Pneumatically actuated vehicle seat assemblies

A technology for vehicle seats and seat components, which is applied to vehicle seats, movable seats, vehicle parts, etc., and can solve the problems of easy-to-wear moving parts, complex and heavy actuation systems, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

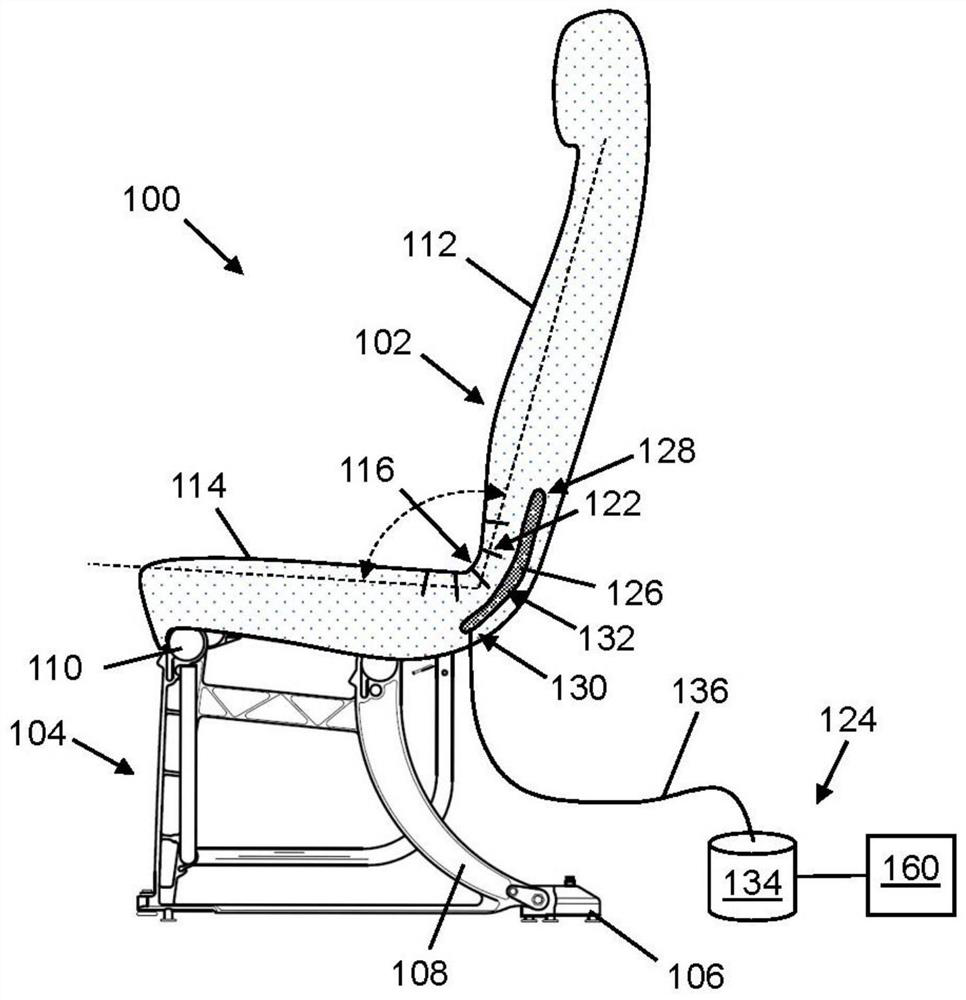

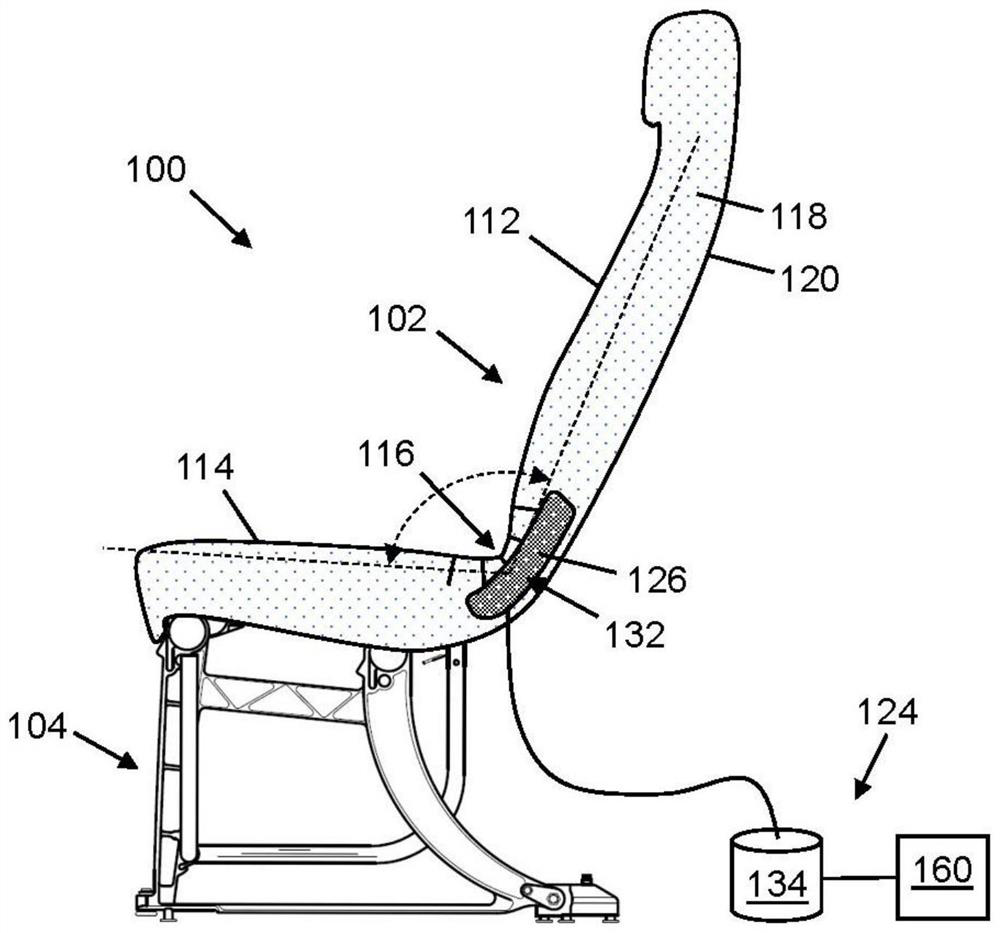

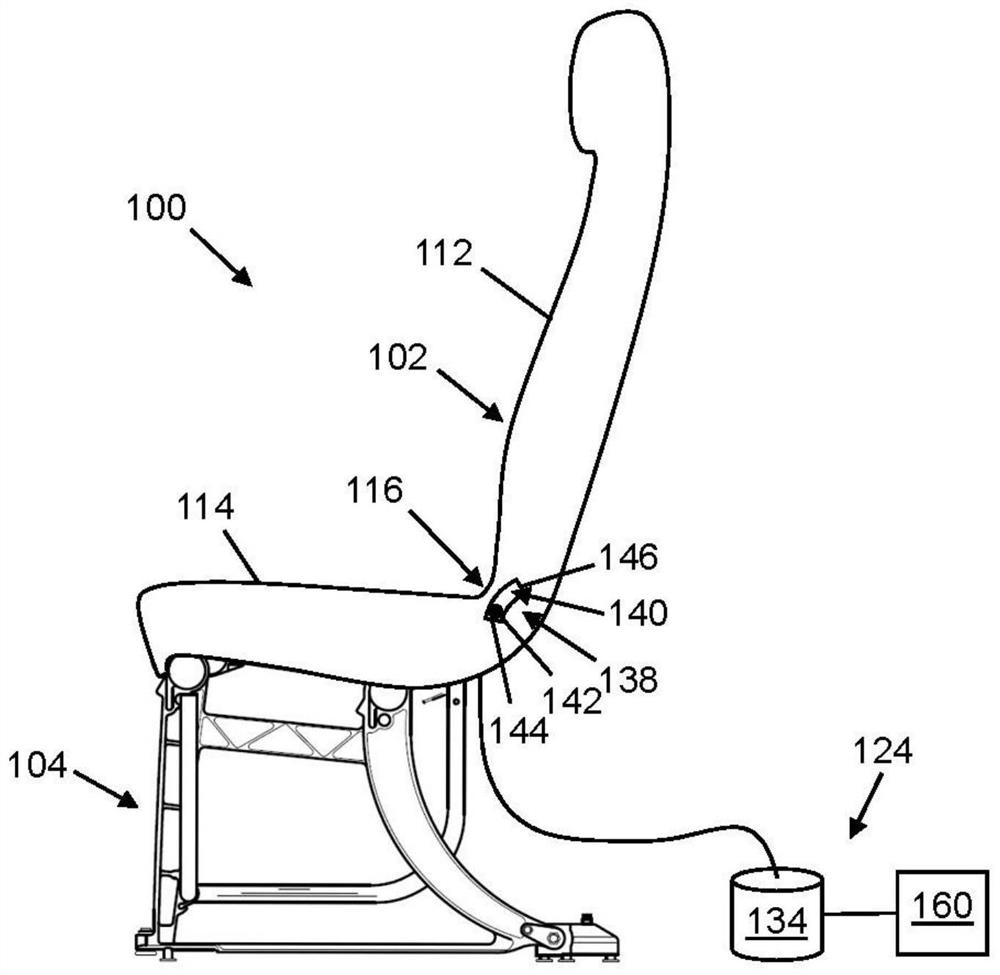

[0035] The following description, taken in conjunction with the accompanying figures, is intended to describe various illustrative embodiments of the disclosed subject matter. Specific features and functions are described in conjunction with each illustrative embodiment; however, it will be apparent to one skilled in the art that the disclosed embodiments can be practiced without each of these specific features and functions. Aspects, features or functions described in conjunction with one embodiment are intended to be applicable to additional embodiments described below unless the aspect, feature or function is explicitly stated to be incompatible with such additional embodiments.

[0036]Exemplary embodiments disclosed herein relate to seat assemblies that include an actuation system for achieving predictable component movement without the need for mechanical and / or electromechanical actuators. The actuation systems disclosed herein include pneumatic or "soft" actuators that...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com