Uniform, accurate and high-precision titanium tetrachloride feeding method

A technology of titanium tetrachloride and feeding method, which is applied in the field of uniform, accurate and high-precision titanium tetrachloride feeding, can solve the problems of deviation, unstable material speed, and difficulty in quality stability, and achieves improved stability and stable transmission. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

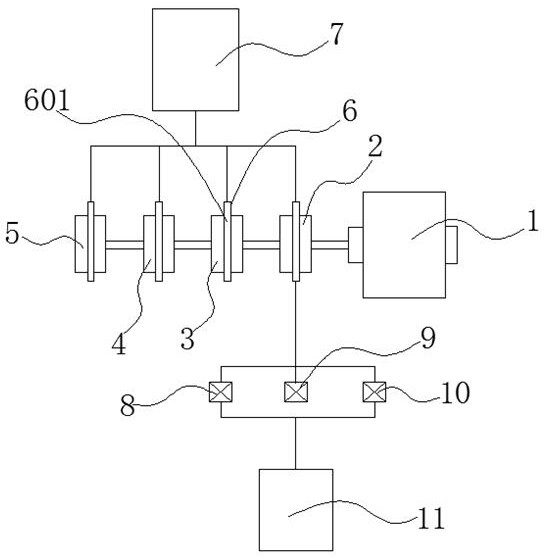

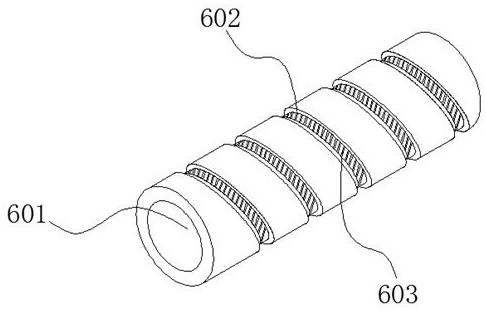

[0027] see Figure 1 to Figure 2 , the present invention provides a technical solution: a uniform, accurate and high-precision titanium tetrachloride feeding method, including the following devices: peristaltic pump 1, valve head A2, valve head B3, valve head C4, valve head D5, special material Pipe 6, storage tank 7, feed valve A8, feed valve B9, feed valve C10 and reactor 11, and the left side of the peristaltic pump (1) are connected with valve head A2, valve head B3, and valve head C4 in sequence from right to left , valve head D5, and the ends of valve head A2, valve head B3, valve head C4, and valve head D5 are all connected with a special material pipe 6, one end of the special material pipe 6 is connected with a storage tank 7, and the special material pipe 6 is another One end is respectively connected with feed valve A8, feed valve B9, and feed valve C10 from left to right, and one end of feed valve A8, feed valve B9, and feed valve C10 is connected with reactor 11 t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com