An underground garage formwork support system

A technology of underground garage and external formwork, applied in the field of building construction, can solve the problems of easy entry of concrete and difficulty in dismantling external hanging formwork, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

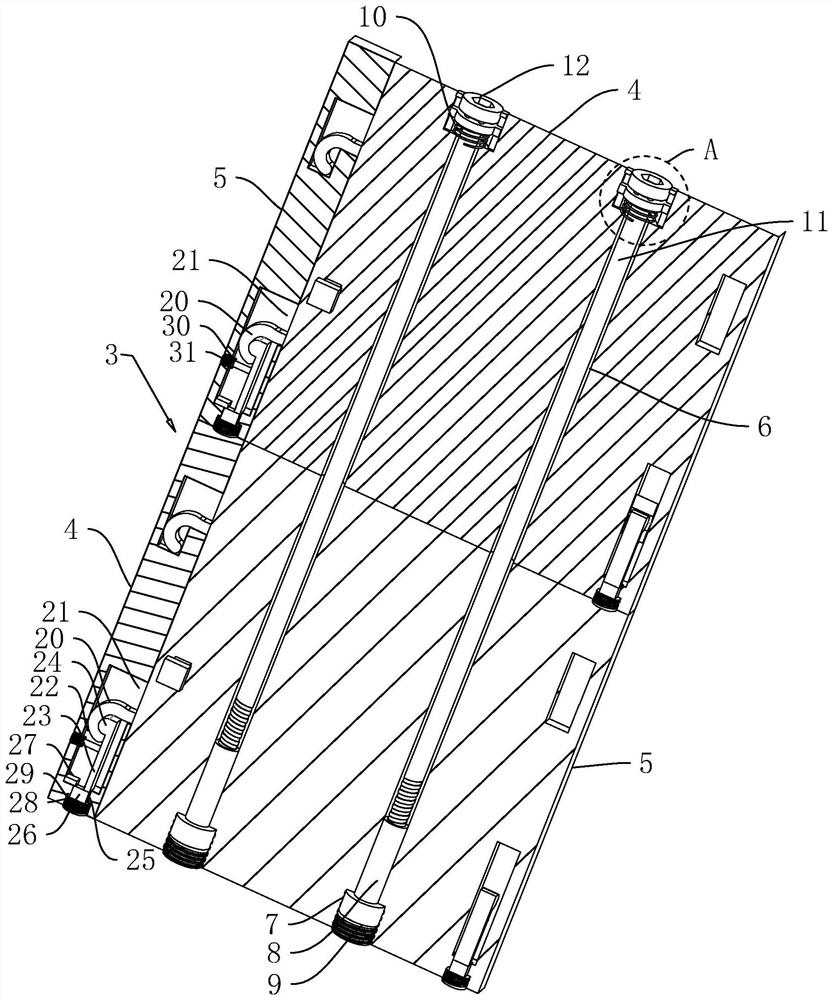

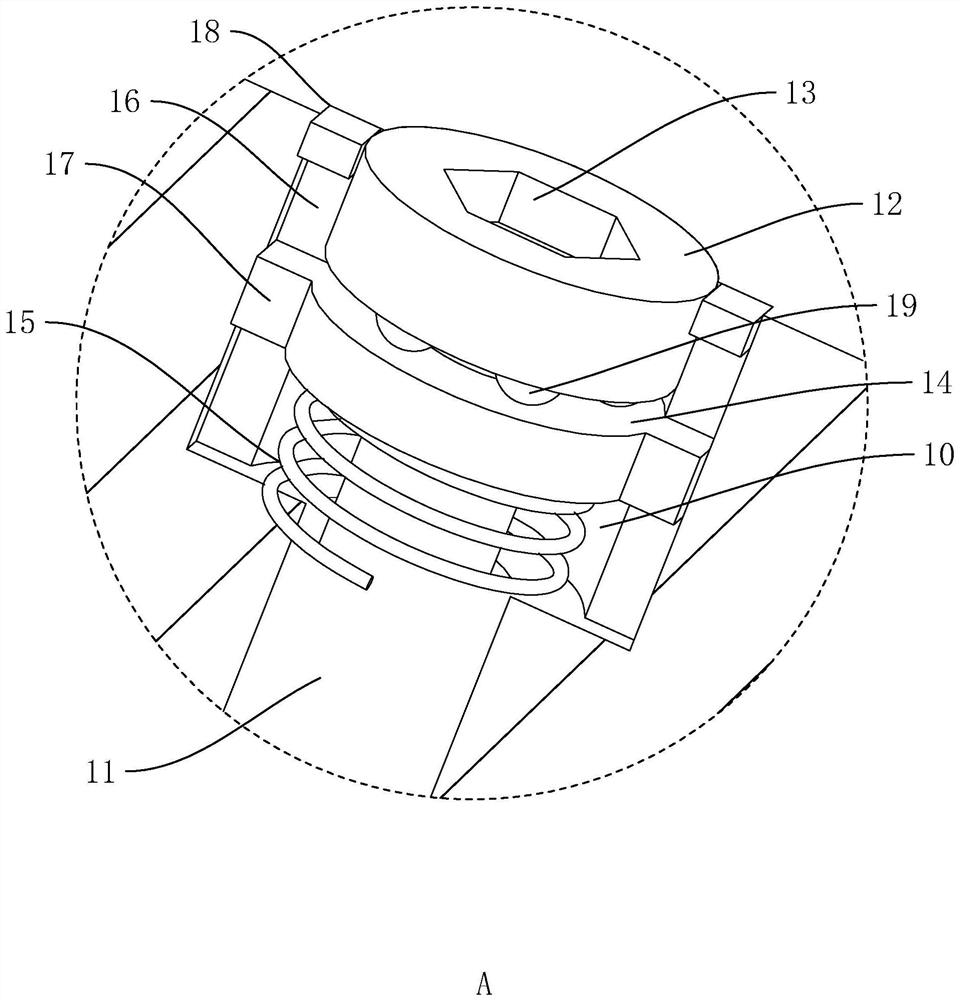

[0035] The following is attached Figure 1-4 The application is described in further detail.

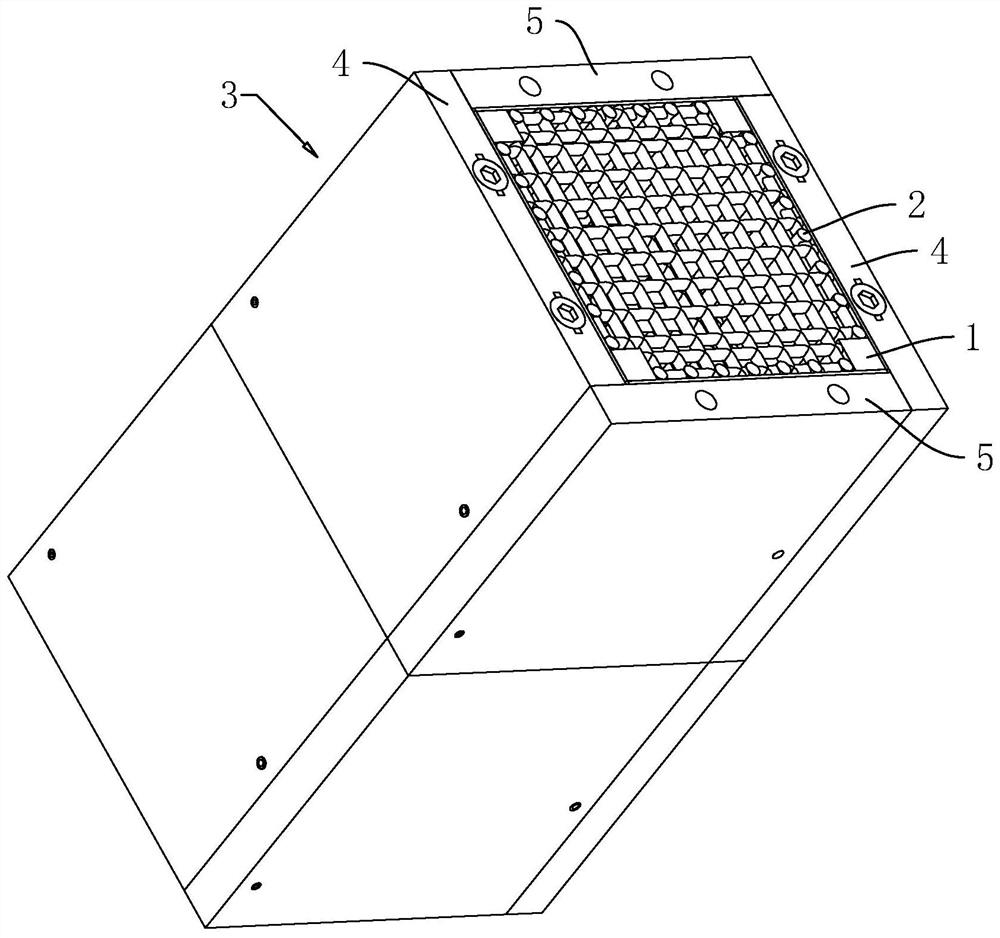

[0036] The embodiment of the present application discloses a formwork support system for an underground garage. refer to figure 1 , including the bracket 1 for fixing the ground, the bracket 1 is located on the four corners of the column to be poured, and the reinforcement cage 2 connecting the bracket 1 is arranged between the brackets 1, and the side wall of the reinforcement cage 2 is flush with the side wall of the bracket 1, forming For the overall structure of the column, concrete is poured into the reinforcement cage 2 to form the column.

[0037] refer to figure 1 and figure 2 , a formwork frame is fixed outside the reinforcement cage 2, the formwork frame is a rectangular frame with a "back" shape in cross section, and the inner wall of the formwork frame abuts against the side walls of the reinforcement cage 2 and the support 1, and the formwork frame is composed of fo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com