Multi-point testing device and testing method based on autocollimator

An autocollimator and testing device technology, which is applied to measurement devices, optical devices, instruments, etc., can solve the problems of low testing efficiency of MEMS micromirror chips and high cost of packaging and testing, so as to improve production and testing efficiency and reduce packaging and testing. cost, the effect of reducing the overall test time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

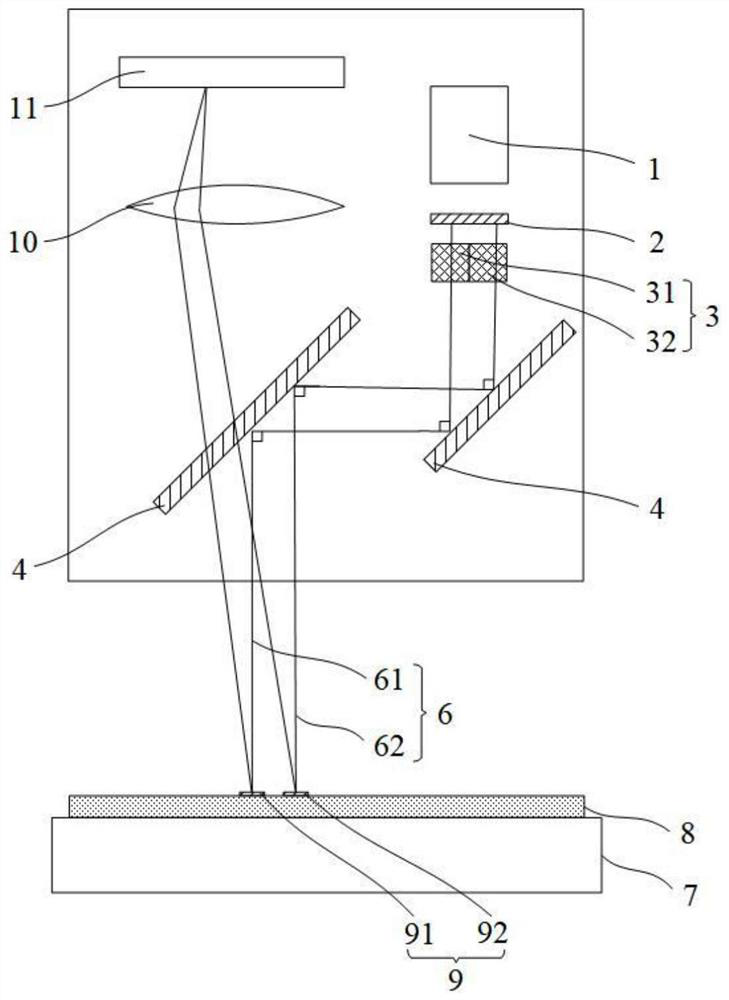

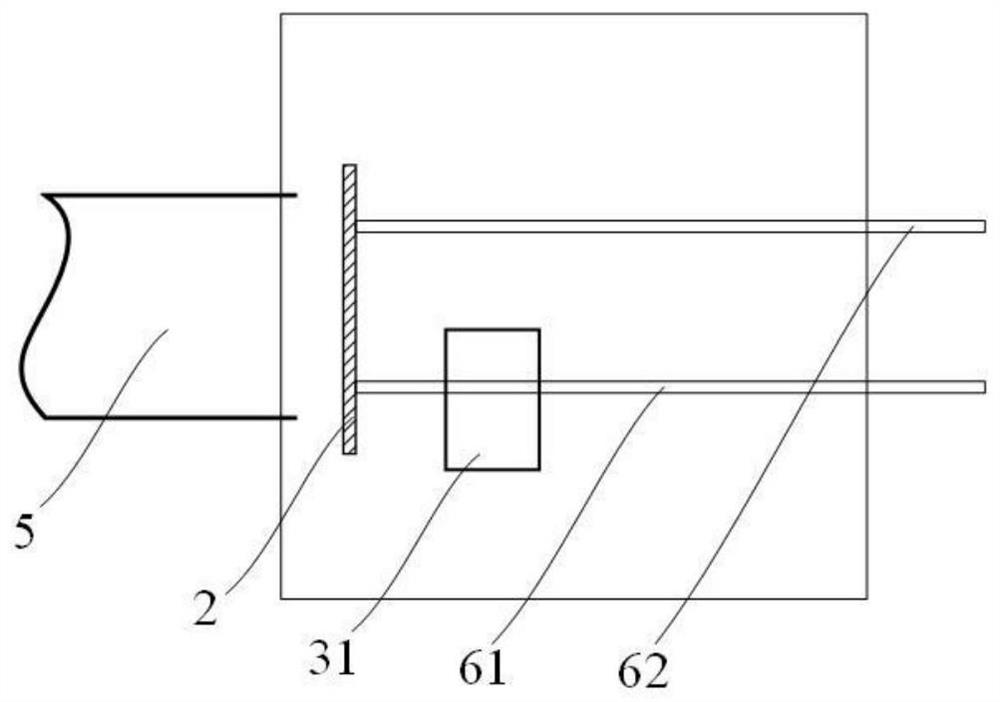

[0069] see figure 1 and figure 2 , the spatial optical switch 3 in the autocollimator-based multi-point testing device provided in this embodiment is composed of only one optical switch (the first optical switch 31). The parallel laser beam 5 produced by the beam expanding and collimating laser light source 1 emits two laser beams through the diaphragm 2, which are respectively the first laser beam 61 and the second laser beam 62, and an optical switch is arranged on the optical path of any one of the laser beams, In this embodiment, one first optical switch 31 is arranged on the optical path of the first laser beam 61 . In addition, the test sequences of the two chips to be tested are different.

[0070] The first optical switch 31 is closed, the first laser beam 61 is blocked by the first optical switch 31, and the second laser beam 62 is not blocked by the optical switch, first test the second laser beam 62 points to the second chip 92 under test. After the test is com...

Embodiment 2

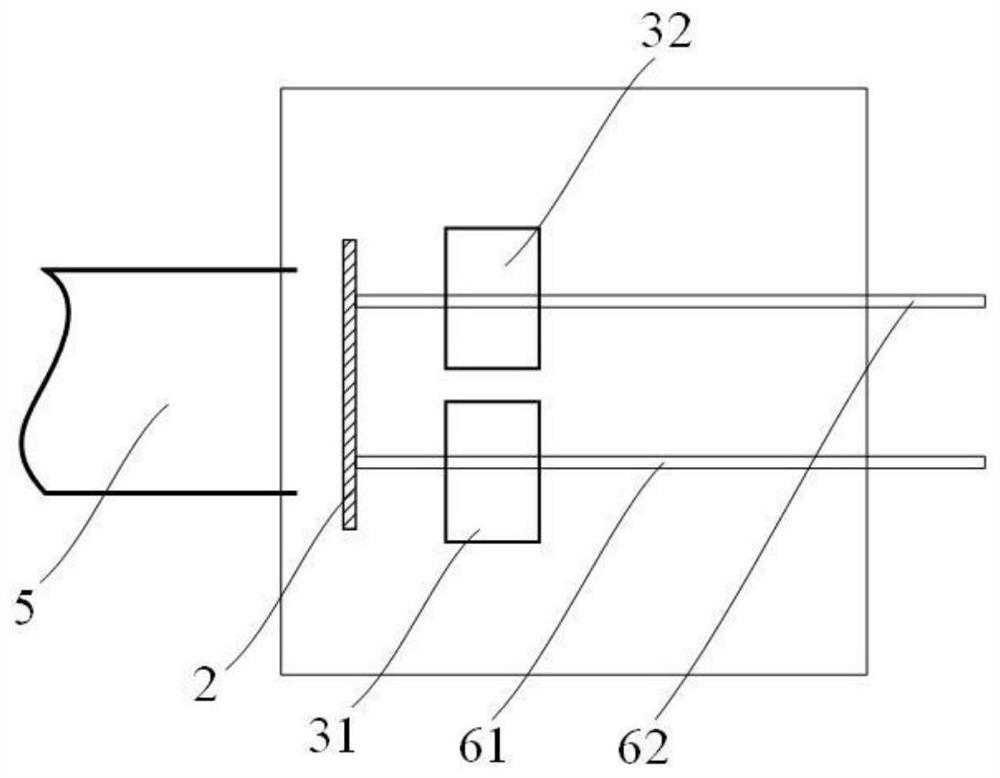

[0072] see figure 1 and image 3 , the spatial optical switch 3 in the autocollimator-based multi-point testing device provided in this embodiment is composed of two optical switches, namely a first optical switch 31 and a second optical switch 32 . The parallel laser beam 5 produced by the beam expanding and collimating laser light source 1 emits two laser beams through the diaphragm 2, which are respectively the first laser beam 61 and the second laser beam 62, and a light beam is respectively arranged on the optical path of the two laser beams. The switches are the first optical switch 31 and the second optical switch 32 respectively. In addition, the test sequences of the two chips to be tested are the same.

[0073] At a certain moment, the first optical switch 31 is turned on, and the second optical switch 32 is turned off to test the first chip under test 91 pointed to by the first laser beam 61; and at the next moment, the first The optical switch 31 is turned off, ...

Embodiment 3

[0075] see figure 1 , Figure 4 and Figure 5 , the spatial optical switch 3 in the autocollimator-based multi-point testing device provided in this embodiment is composed of four optical switches. The parallel laser beam 5 produced by the beam expanding and collimating laser light source 1 emits four beams of laser light through the diaphragm 2, and an optical switch is respectively arranged on the optical path of each laser beam, which are respectively denoted as the first optical switch 31 and the second optical switch. 32. The third optical switch 33 and the fourth optical switch 34. In addition, the test sequences of the four chips to be tested are the same, and the four chips to be tested can be tested sequentially. The difference between this embodiment and the second embodiment is only that the number of laser beams and corresponding lights is increased, and the test method is the same, and will not be repeated here.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com