Mueller matrix detection device calibration method

A Mueller matrix and detection device technology, which is applied in the calibration field of Mueller matrix detection devices, can solve the problems of not considering the influence of incident light obliquely entering the Mueller matrix detection device error, and unsatisfactory

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

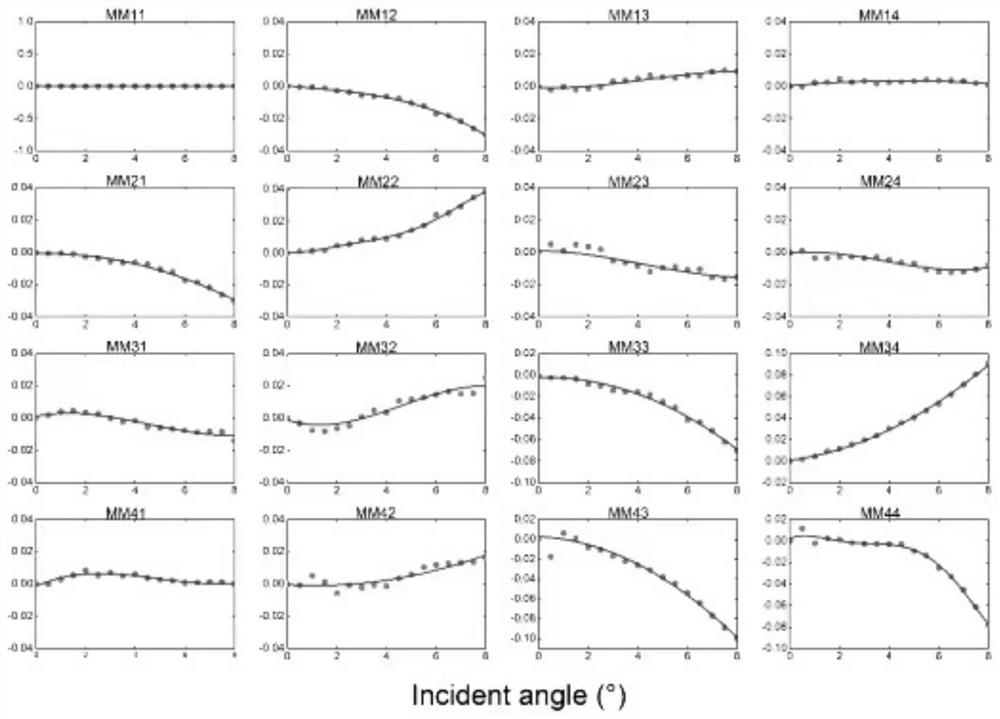

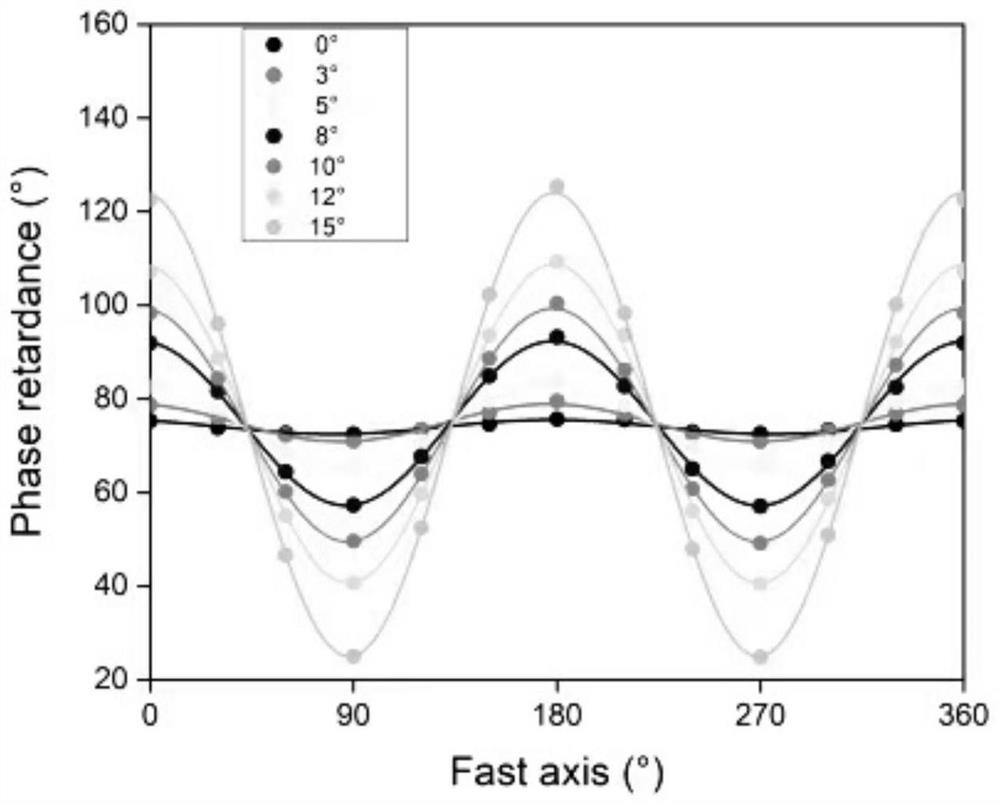

[0046] Based on the fact that the existing Mueller matrix detection device has the wave plate due to improper installation, defects in the processing process or the approximate collimation of the cone beam in the actual optical path, the light is obliquely incident, the applicant uses the existing Mueller matrix detection device The device is transformed into an oblique incidence Mueller matrix detection device, simulating the oblique incidence of incident light to the surface of a quarter-wave plate, and observing the change trend of the Mueller matrix elements of the sample measured under oblique incidence conditions, so as to determine the oblique incidence of light influences.

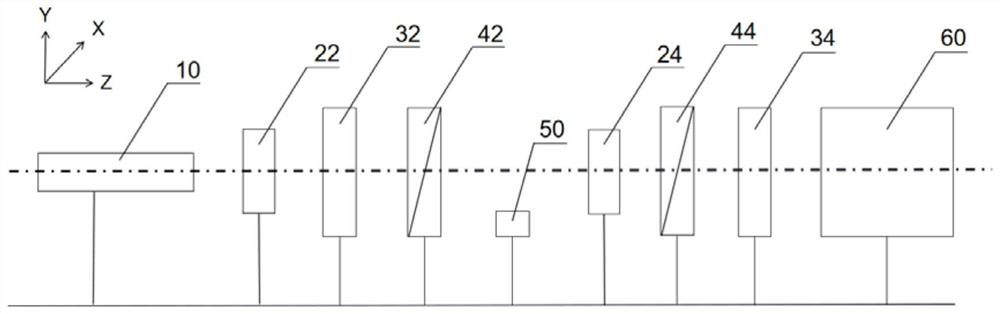

[0047] see figure 1 , figure 1 It is a structural schematic diagram of an oblique incidence Mueller matrix detection device for simulating oblique incidence of light in the present invention. The oblique incidence Mueller matrix detection device comprises a light source 10, a collimator lens 24, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com