Winding AC resistance measurement method and system

A technology of AC resistance and measurement method, applied in the direction of measurement device, measurement of electrical variables, measurement of resistance/reactance/impedance, etc., can solve problems such as increasing the difficulty of project implementation, lack of space, and restricting applications, and expand the measurement frequency range. , the effect of improving the degree of coupling and reducing the difficulty of implementation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

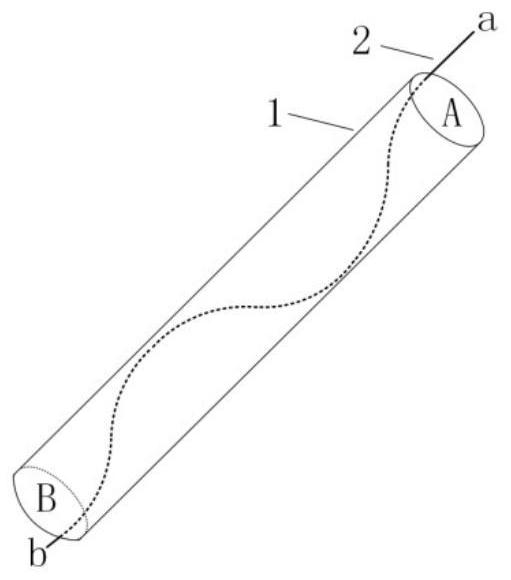

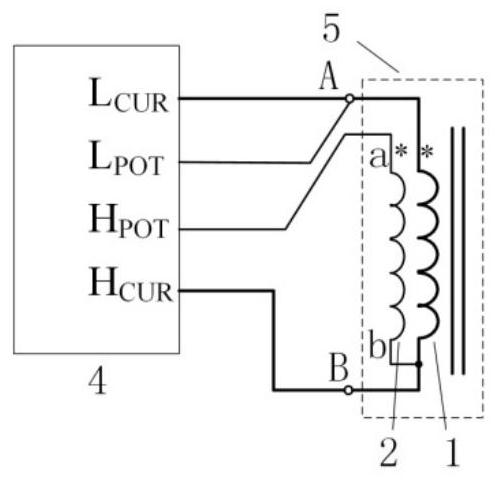

[0051] Example 1, such as figure 1 The schematic diagram of the tested winding and auxiliary winding is shown, the tested winding 1 is a multi-strand enameled stranded wire (Litz wire), the auxiliary winding 2 is a randomly selected single-strand wire in the tested winding 1, and the auxiliary winding 2 and the The other strands in winding 1 are insulated from each other. Since there is no need to additionally arrange auxiliary windings in the magnetic component under test, the difficulty of engineering implementation is reduced. The two ends of the measured winding 1 are respectively B and A, and the two ends of the auxiliary winding 2 are respectively b and a. Terminal a of winding 2 has no direct electrical connection. Due to the tight twisting of the winding 1 under test, the coupling degree between the auxiliary winding 2 and the winding 1 under test is much greater than that when an additional auxiliary winding is arranged, which can be used for high-precision measurem...

Embodiment 2

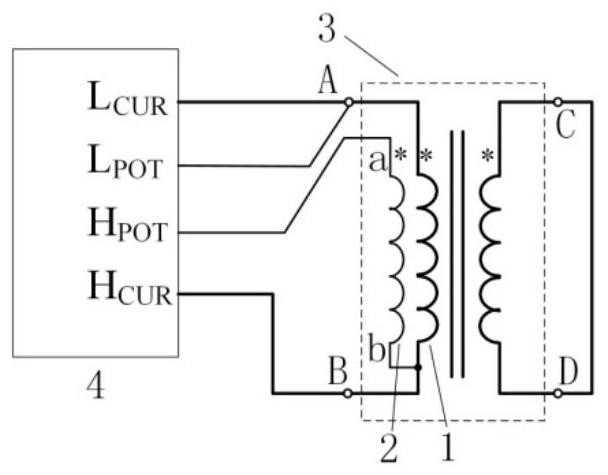

[0053] Example 2, image 3 An embodiment of measuring the AC resistance of a transformer winding by the method of the present invention is shown, and the embodiment includes an impedance measuring instrument 4 and a transformer under test 3 . The other windings in the tested transformer 3 except the tested winding 1 and the auxiliary winding 2 are short-circuited.

[0054]Compared with the prior art, the present invention has the following advantages: (1) It is unnecessary to arrange additional auxiliary windings in the magnetic element under test, which reduces the difficulty of engineering implementation; It is suitable for high-precision measurement of AC resistance of high-power windings, and at the same time expands the measurement frequency range.

[0055] Those skilled in the art should understand that the embodiments of the present application may be provided as methods, systems, or computer program products. Accordingly, the present application may take the form of ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com