A measurement method of rail level irregularity based on single-axis gyroscope

A technology of unevenness and measurement methods, applied in the direction of measuring devices, instruments, etc., can solve the problems of poor detection accuracy and data completion, slow information transmission speed, and high labor intensity of workers, so as to achieve convenient implementation, low engineering construction difficulty and low cost. low effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

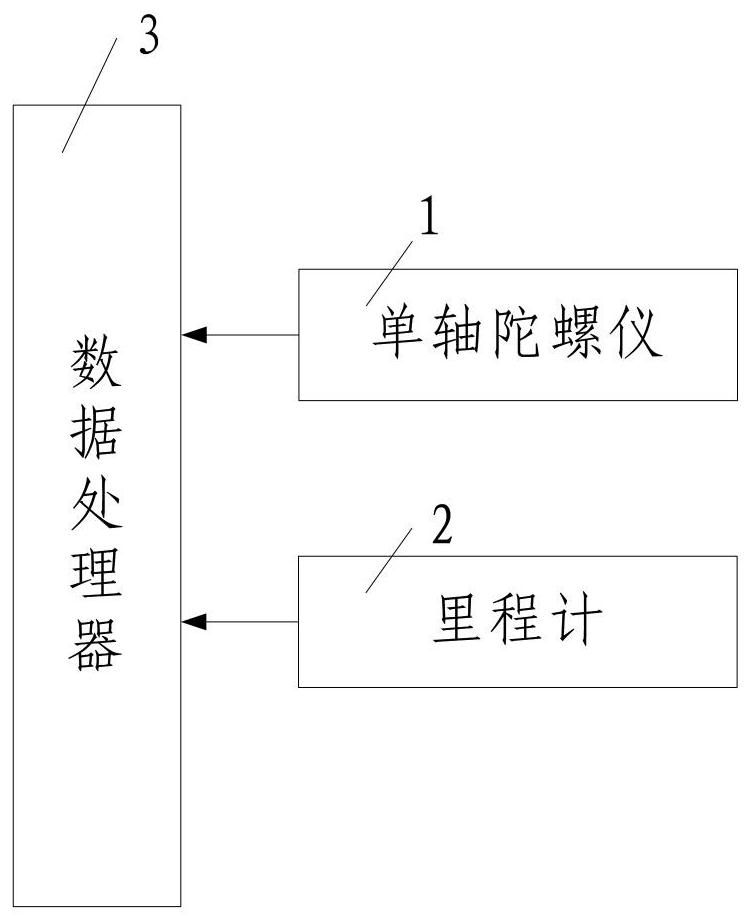

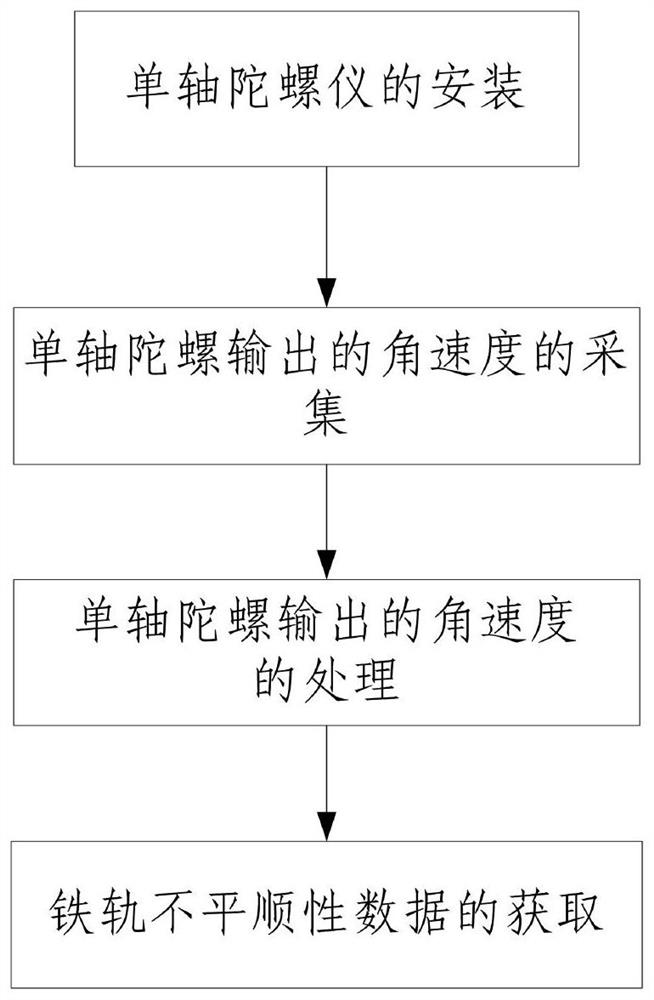

[0053] Such as figure 1 and figure 2 A method for measuring the unevenness of rail tracks based on a single-axis gyroscope includes the following steps:

[0054] Step 1. Installation of single-axis gyroscope:

[0055] Step 101, fixing the single-axis gyroscope 1 on the rail inspection vehicle; wherein, the angle between the measurement axis of the single-axis gyroscope 1 and the moving direction of the rail inspection vehicle is 0° or 180°;

[0056] Step 102, placing the rail inspection car equipped with the single-axis gyroscope 1 on the rail to be tested;

[0057] Step 2. Acquisition of the angular velocity output by the single-axis gyroscope:

[0058] Step 201, the rail inspection car is stationary for 5 minutes to 10 minutes for the ath time; wherein, the speed and angular velocity of the rail inspection car are both zero; a is a positive integer, and a≥1;

[0059] Step 202, when the rail inspection vehicle is still for the a-th time, the data processor 3 collects the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com