Parabolic base resonance type curved surface bulldozing plate and setting method of soil touching curved surface

A technology of parabola and bulldozing blades, which is applied to earth movers/shovels, complex mathematical operations, construction, etc. It can solve problems such as high power consumption and large working resistance of bulldozing blades, and achieve strong adaptability and reduce work Effect of improving resistance and drag reduction performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] The present invention will be further described in detail below in conjunction with the drawings and embodiments, but it is not used as a basis for any limitation on the invention.

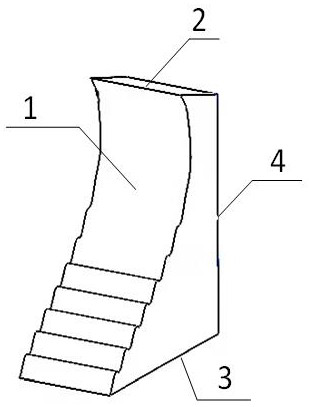

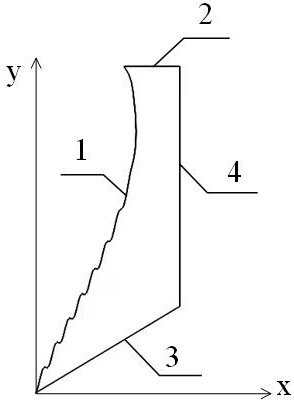

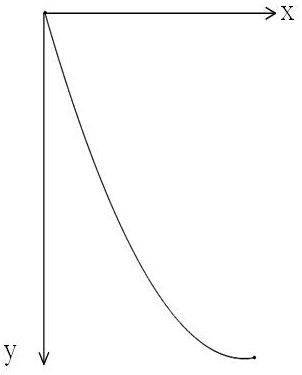

[0029] Referring to the accompanying drawings, a parabolic base resonant curved surface bulldozer is provided with a soil contact surface 1, an upper end surface 2, a lower end surface 3 and a rear end surface 4, the soil contact surface 1 is set opposite to the rear end surface 4, and the soil contact surface An upper end surface 2 is provided between the top of the curved surface 1 and the rear end surface 4, and a lower end surface 3 is provided between the bottom of the soil-touching curved surface 1. During operation, the upper end surface 2 is horizontal, and the angle between the lower end surface 3 and the horizontal plane is 30°. The contour line of the soil-touching surface 1 is a complex curve, and the equation of the complex curve is a parametric equation:

[0030] Among them,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com