A variable curvature excavator bucket

A technology of variable curvature and machine shovel, applied in mechanically driven excavators/dredgers, earth movers/shovels, construction, etc., can solve the problems of complex mechanism design, unfavorable soil loosening, and large working resistance, etc. Achieve the effect of solving the large working resistance, changing the soil movement mode, and improving the ability to enter the soil

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

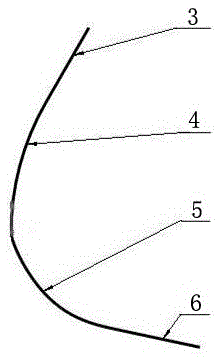

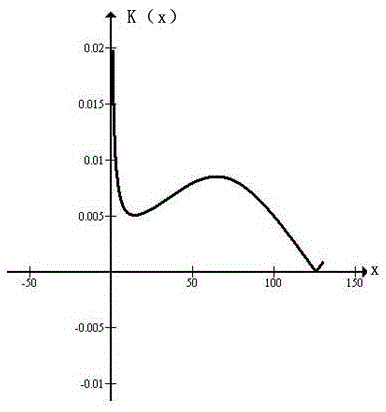

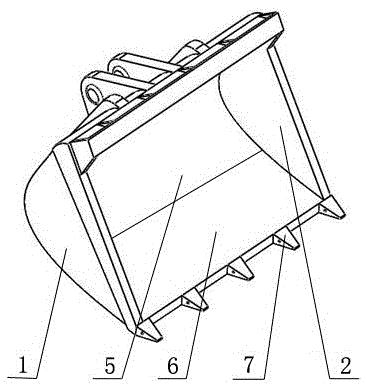

[0021] A variable-curvature excavator bucket, mainly related to the soil-contacting curved surface of the bucket, especially the inner contour of the curved surface. The bucket is composed of four parts, which are as follows from front to back: bucket front wall plate 6, bucket bottom plate 5 , bucket rear wall plate 4 and overflow prevention plate 3, the curve forms corresponding to each part successively are: straight line, compound curve type with variable curvature, arc shape and straight line type. That is: the soil contact curve of the bucket front wall plate 6 is a straight line, and its curvature is constant 0; the soil contact curve of the bucket bottom plate 5 is a variable curvature equation curve, and its curvature changes as follows: figure 2 As shown; the soil contact curve of the bucket rear wall plate 4 is a circular arc curve, and its curvature is the reciprocal 1 / r of the arc radius r; the soil contact curve of the overflow prevention plate 3 is linear, and i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com