Paper box opening cutting process and box opening device

A cutting process and carton technology, applied in packaging, papermaking, transportation and packaging, etc., can solve problems such as burrs, blade wear, defective products, etc., achieve smooth cutting effect, prolong passivation period, and reduce the probability of burr phenomenon. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0027] This embodiment provides a solution to make the cutting effect of the box mouth more smooth and beautiful.

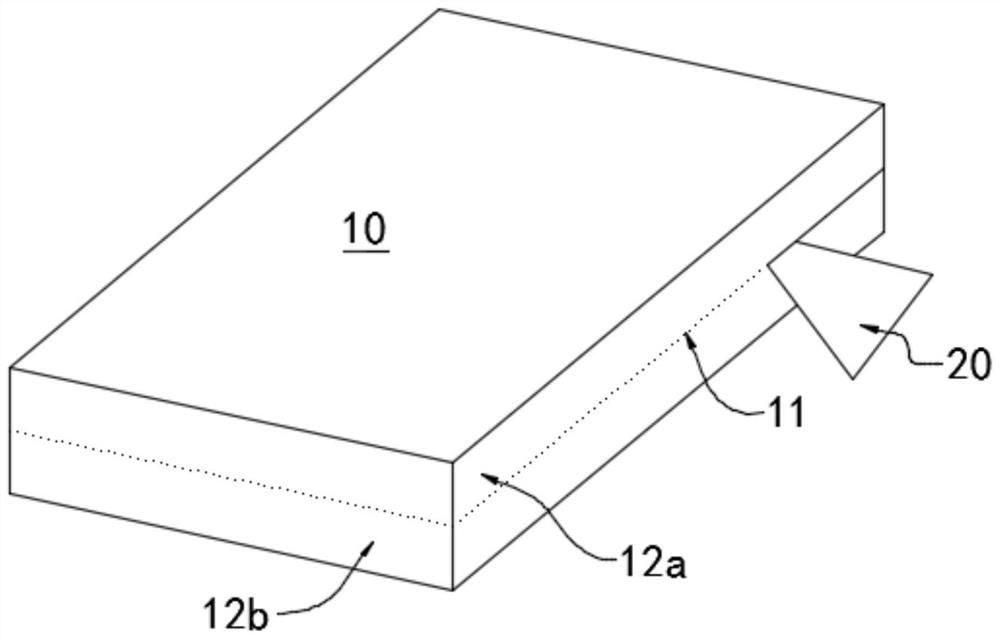

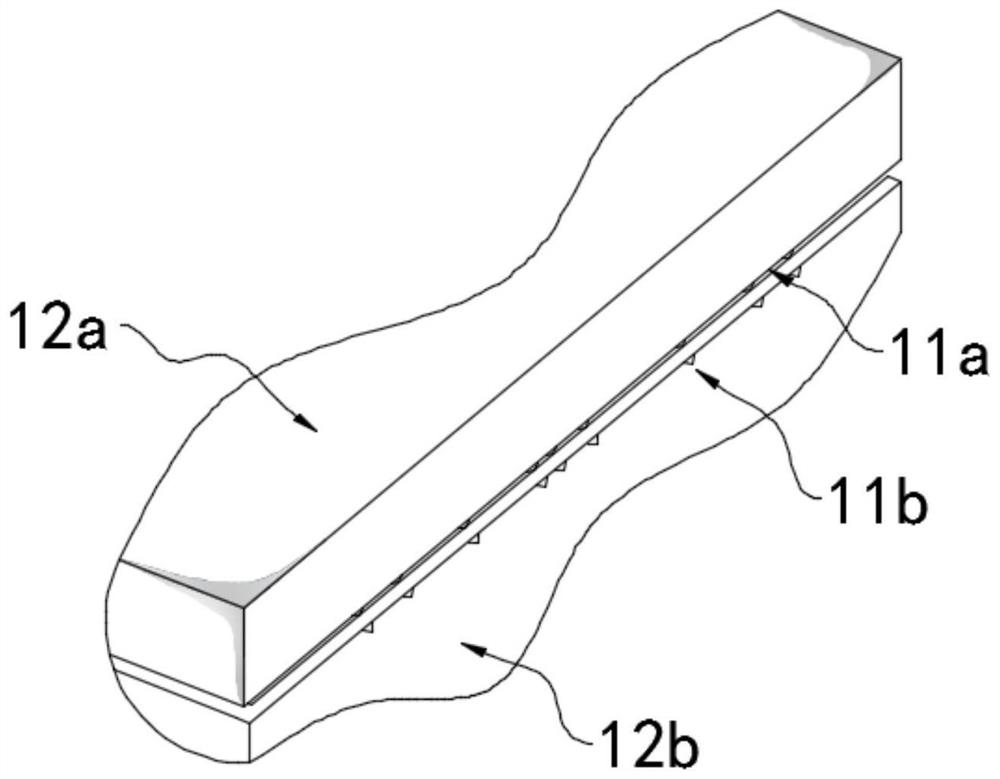

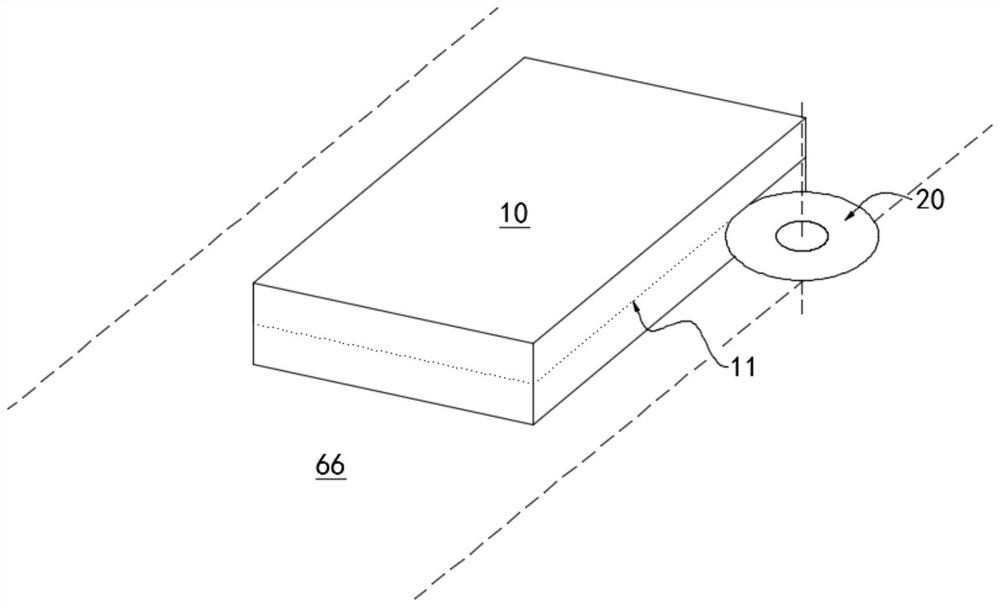

[0028] Such as image 3 As shown, the incoming material of the carton 10 is block-shaped, and its thickness faces four different directions. The carton is conveyed on the conveying path 66, and the surface to be cut of the carton is the surface in three directions of the thickness surface, towards the edge of the conveying path 66; a cutter 20 is set on the edge of the conveying path 66, when the carton is along the conveying path 66 when advancing, the cutting knife 20 cuts the paper material to be cut along the roll of the surface to be cut close to it; wherein, the cutting knife 20 can rotate.

[0029] Measure the size of the box type in advance, adjust the width of the conveying path 66, make the carton 10 keep walking in a straight line on the conveying path, and adjust the degree of slight extrusion between the blade of the cutter 20 and a cut surface of t...

Embodiment 2

[0034] This embodiment provides a solution to make the cutting effect of the box mouth more smooth and beautiful, and also has the convenience of automatic processing.

[0035] Such as Figure 4 , the conveying path 66 is configured as at least two, one conveying path 66a is provided with cutters on both side edges, and the other conveying path 66b is provided with a cutter on one side edge, and the two conveying paths are perpendicular to each other. The carton can pass through the conveying path 66a first, so that its two faces to be cut are cut on this conveying path 66a, and at the end of this path, keep its posture unchanged, and then be cut on another conveying path 66b for the second time. Three sides to be cut.

[0036] The form of pushing the carton on the conveying path can have many forms, such as two vertically arranged chain plates or two pushing block structures to continue pushing the box to change its walking direction.

Embodiment 3

[0038] This embodiment provides a solution to make the cutting effect of the box mouth more smooth and beautiful, and also provides a cutting knife assembly with high straightness and low cost.

[0039] Figure 5 It is the first embodiment of the cutter assembly, which has the cheapest cost and is the easiest to assemble and disassemble. The cutter assembly includes a cutter 20, a connecting shaft 21, a bearing 22, a bushing 23 and a mounting seat 24. The connecting shaft 21 is radially provided with a boss, and the cutter 20 is set on the connecting shaft and is stuck on one side by the boss. One side is supported by the inner ring 22a of the bearing 22, and the connecting shaft 21 is tightened from the upper end to realize the fixed connection between the connecting shaft 21, the cutter 20 and the inner ring 22a of the bearing, and the bushing 23 connects the outer ring 22b of the bearing 22 to the mounting seat 24 fixed directly or indirectly. When the carton is in contac...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com