A variable curvature conventional plow

A plough-type plough and variable curvature technology, applied in ploughs, agricultural machinery and implements, applications, etc., can solve the problems of high adhesion, short service life, large working resistance, etc., and achieve the effect of reducing resistance and reducing contact probability.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

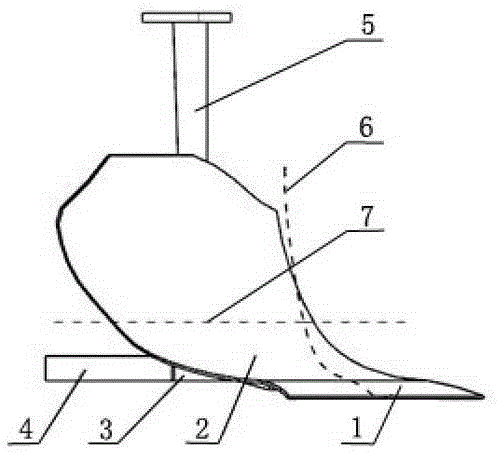

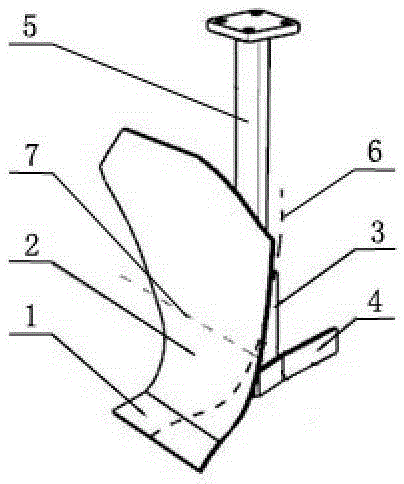

[0023] like figure 2 , 3 As shown, a variable-curvature mower plow includes a plowshare 1, a plowboard 2, a plow holder 3, a plow side plate 4 and a plow post 5. It is fixedly connected with the plow column 5, and a plow side plate 4 is arranged on the plow holder 3 along the direction of the plow plow.

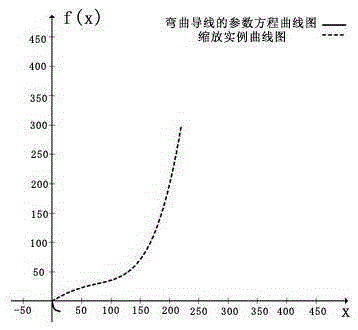

[0024] Among them, the upper surface of the plow share 1 and the plow wall 2 constitutes a curved surface of the plow body that touches the soil, and the curved surface of the plow body is formed by the continuous movement of the straight element line 7 parallel to the horizontal plane on the curved wire 6 according to a certain element line angle. , the curved wire 6 is given by the parametric equation , where the value range of x is 0~18. Further, the curved wire 6 is a curve segment obtained by scaling the same ratio in the x and f(x) directions respectively within the range of x from 0 to 18 mm.

[0025] like Figure 5 As shown, it is the parametric equation curve ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com