Self-adaptive anti-fogging hot-line work lens and control method thereof

A live working and control method technology, applied in the direction of electric heating devices, electrical components, transparent/reflective heating devices, etc., can solve problems such as lens fogging, and achieve the effect of eliminating potential safety hazards and clear vision

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

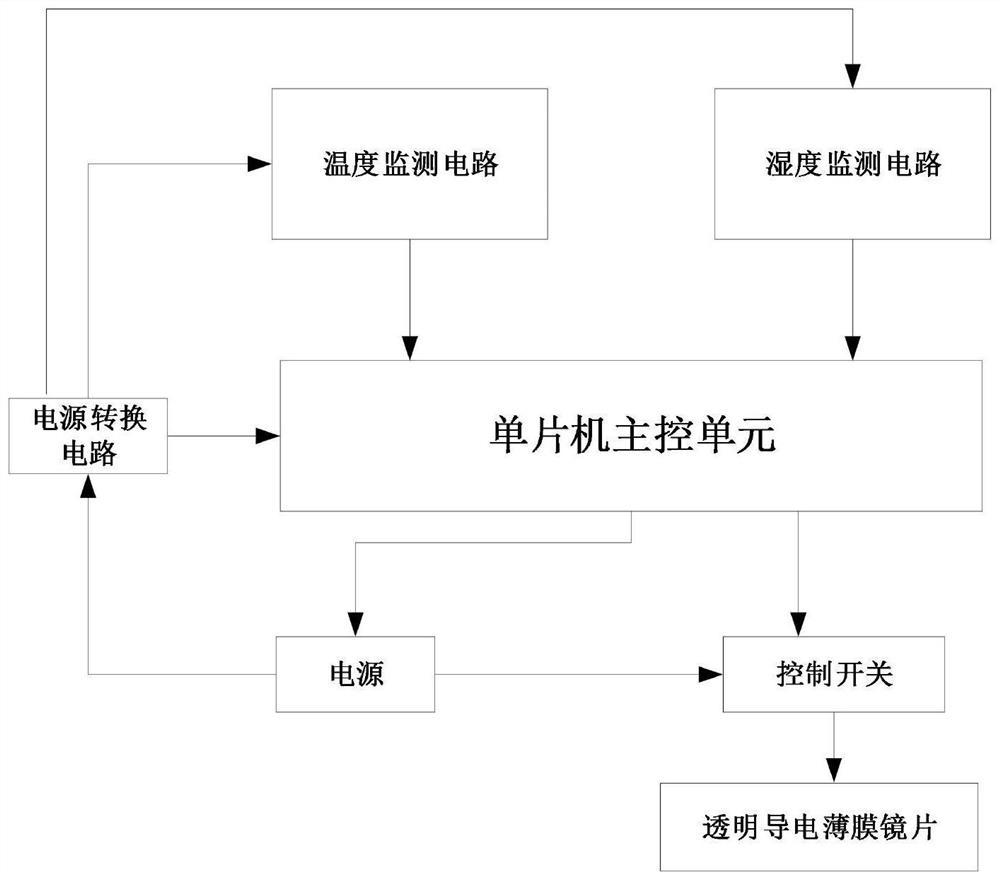

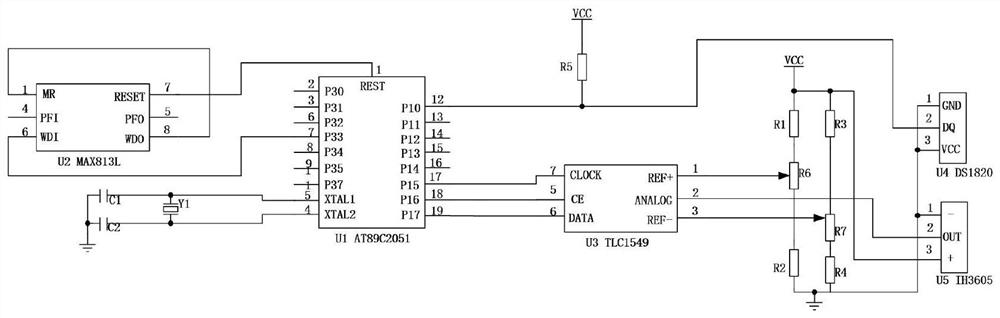

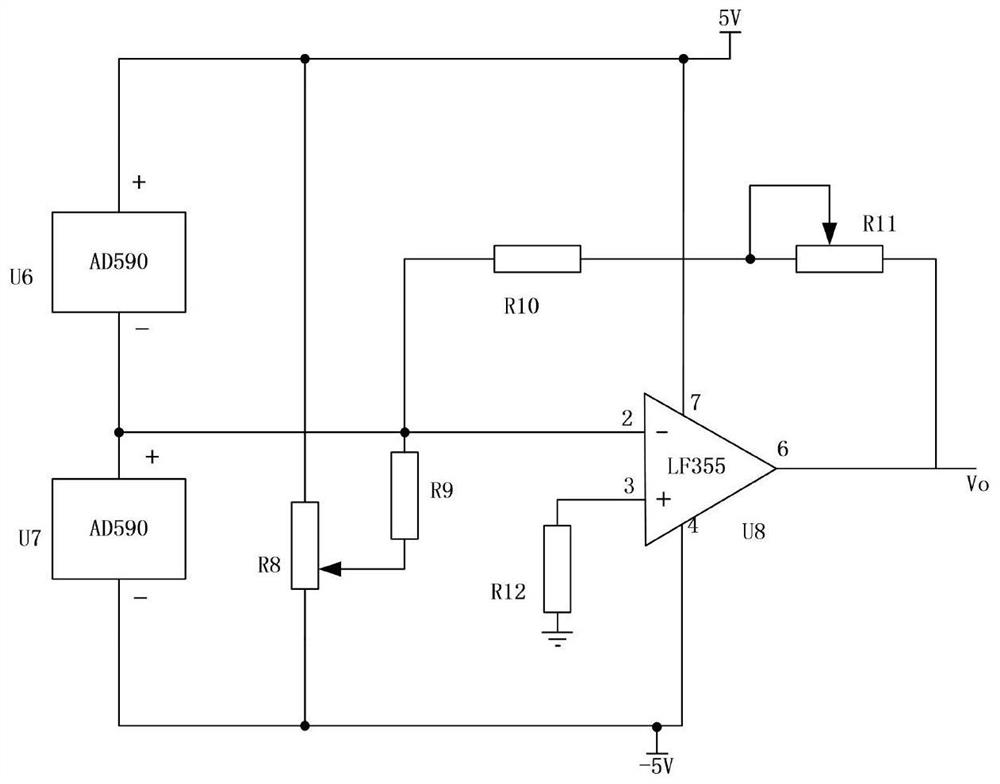

[0044] A self-adaptive anti-fog liveline operation, such as figure 1 As shown, it includes a transparent conductive film lens, a mirror frame, a power supply, a control switch, a temperature monitoring circuit, a humidity monitoring circuit, a power conversion circuit, and a single-chip main control unit. The power supply is a battery pack, and the control switch is a thyristor switch.

[0045] The battery pack is used to provide the required DC power for the temperature monitoring circuit, humidity monitoring circuit, single-chip microcomputer main control unit and transparent conductive film lens; the single-chip microcomputer main control unit adopts AT89C2051.

[0046] The output end of the temperature monitoring circuit is connected with the input end of the single-chip main control unit, the output end of the humidity monitoring circuit is connected with the input end of the single-chip main control unit, the output end of the single-chip main control unit is connected wi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com