Negative pressure suction front end and negative pressure suction system

A negative pressure and suction device technology, applied in the field of negative pressure equipment, can solve the problems of poor adsorption effect and low adsorption efficiency, and achieve the effects of complete treatment, elimination of harmful pollution, and guarantee of clarity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

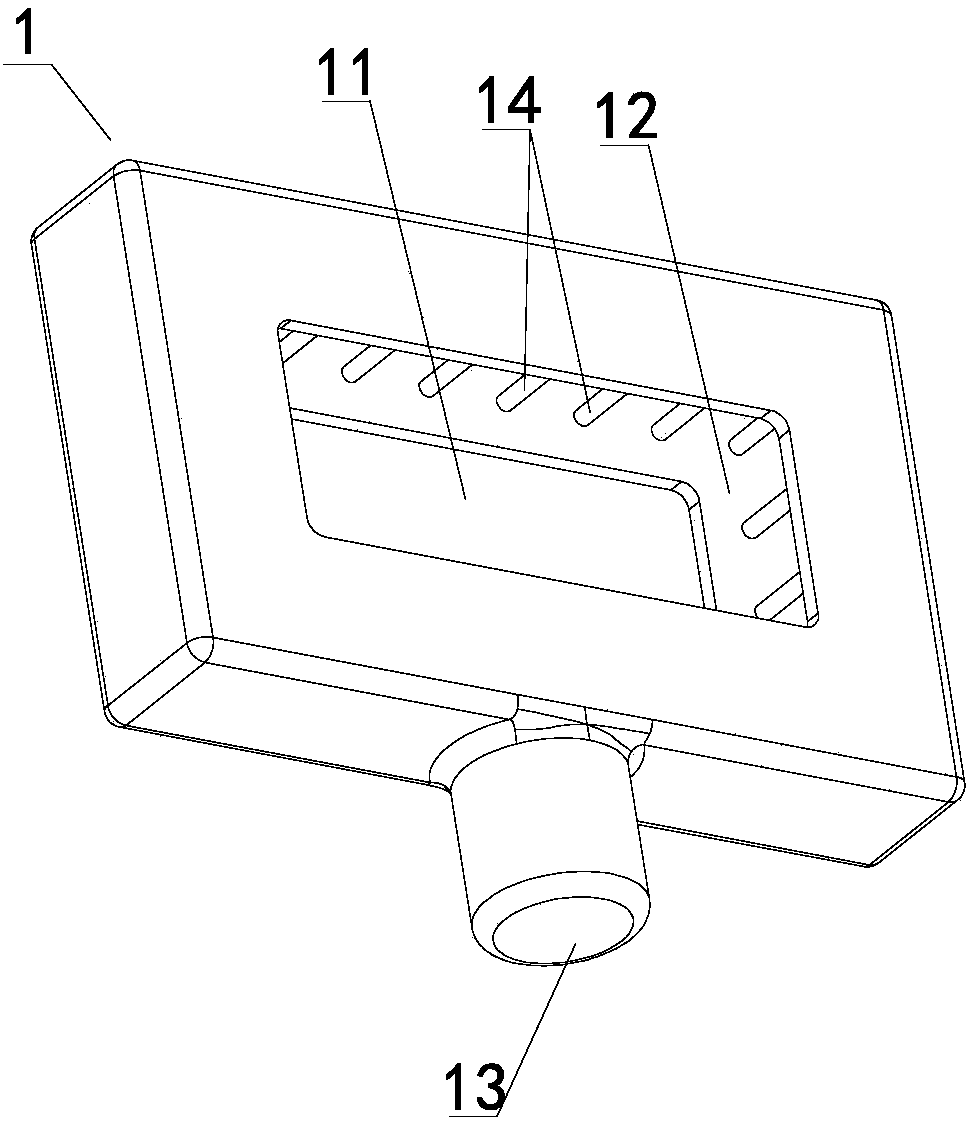

[0040] combine Figure 1-Figure 2 As shown, a negative pressure suction front end provided in Embodiment 1 of the present invention may include a suction cabin 1; the suction cabin 1 may have a ring structure, and the side of the suction cabin 1 facing the area surrounded by the ring structure is provided with a suction port 12, The suction chamber is also provided with a discharge port 13 for communicating with a negative pressure source. Wherein, the area surrounded by the above-mentioned annular structure can form the operating channel 11 for surgery, and the suction port 12 is set towards the operating channel 11, which can absorb smoke, particles and odors at the surgical wound in time.

[0041] In the specific operation, the present invention can provide the necessary passages required for surgical wound operation through the above-mentioned operation channel 11, which can effectively meet the actual needs; the setting of the negative pressure source through the above-me...

Embodiment 2

[0052] The substantial difference between the second embodiment and the first embodiment lies in: the specific setting of the operation channel is different.

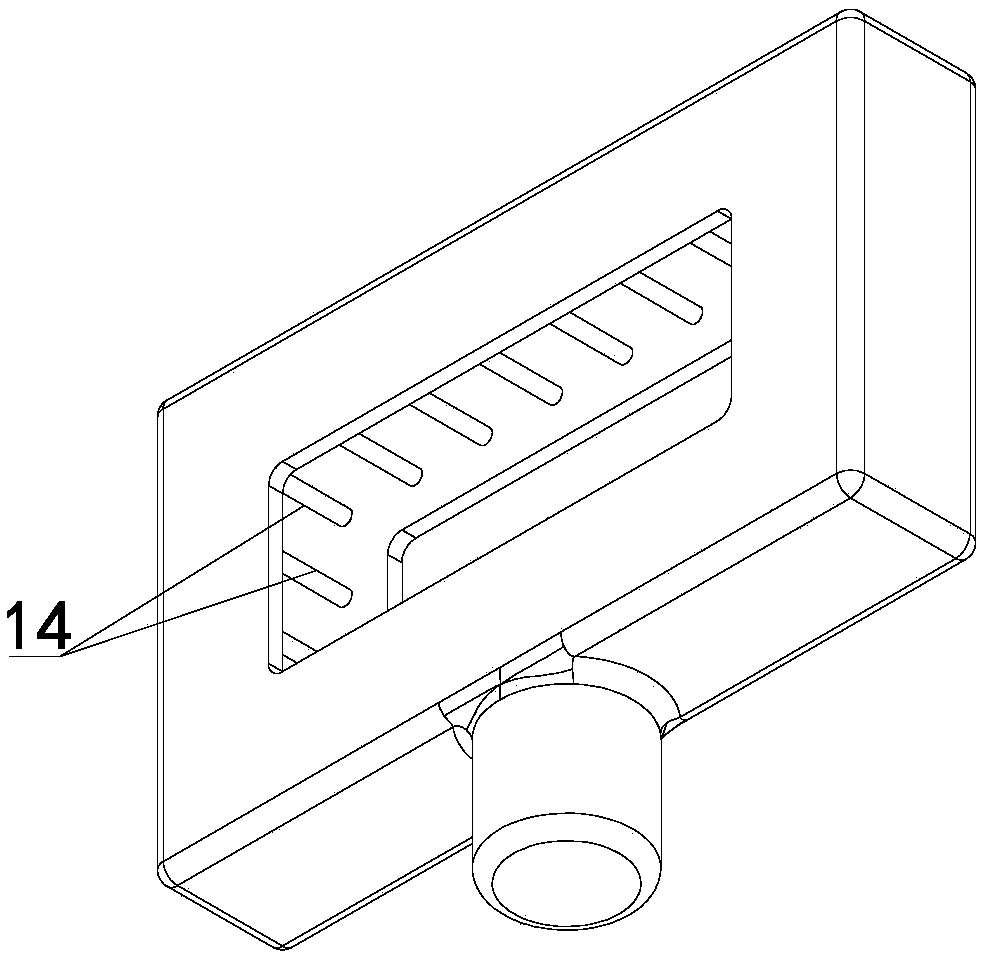

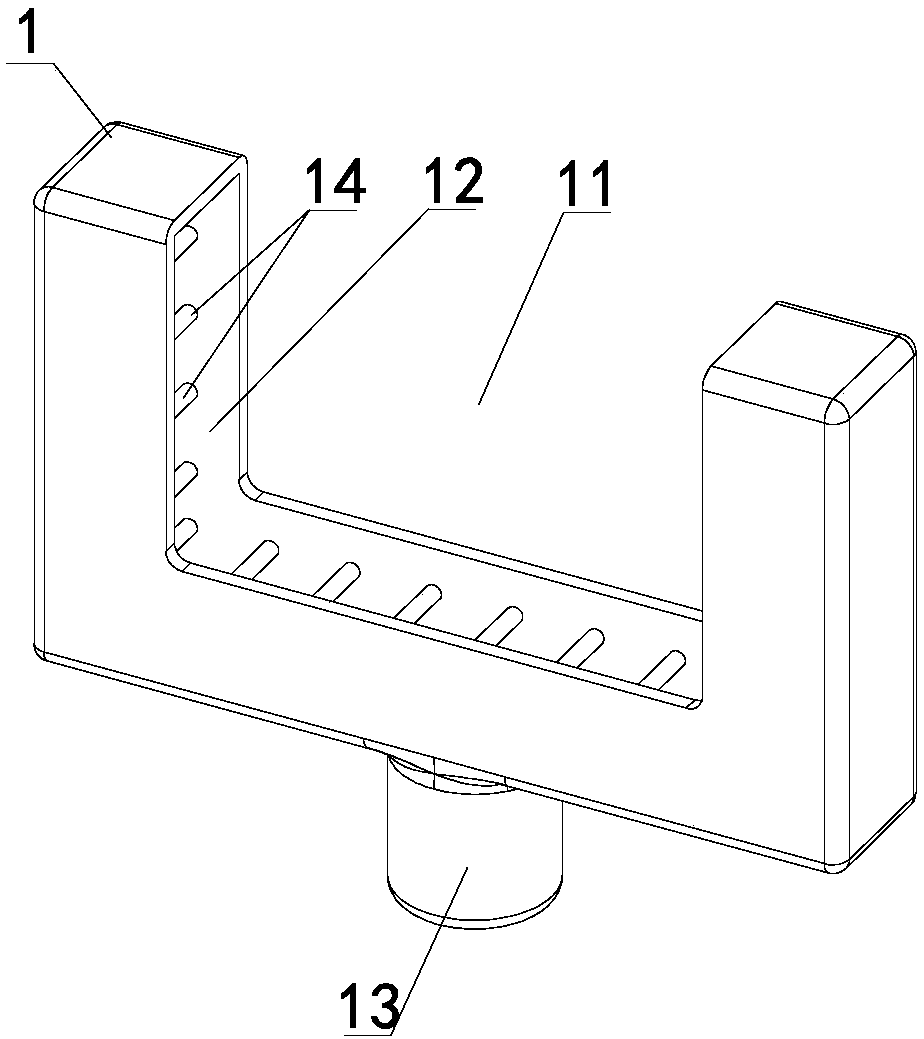

[0053] combine Figure 3-Figure 4 As shown, in the negative pressure suction front end provided in the second embodiment of the present invention, the main structure is similar to that of the first embodiment, the suction cabin 1 also has a ring structure, and the side of the suction cabin 1 facing the area surrounded by the ring structure is provided with a suction port 12. The suction chamber is also provided with a discharge port 13 for communicating with a negative pressure source. For the specific description of the above structure, please refer to the description in Embodiment 1. This embodiment aims to illustrate the difference between the two.

[0054] In this embodiment, the above-mentioned annular structure is a split ring, that is, the above-mentioned operation channel 11 has an opening area partially contai...

Embodiment 3

[0057] The substantial difference between the third embodiment and the first embodiment lies in: the specific setting of the suction cabin is different.

[0058] A negative pressure suction front end provided in Embodiment 3 of the present invention has a main structure similar to that of Embodiment 1. The suction cabin also has a ring structure. The side of the suction cabin facing the area surrounded by the ring structure is provided with a suction port, and the suction cabin is also provided with a suction port. There is a discharge port for connecting with a negative pressure source. For the specific description of the above structure, please refer to the description in Embodiment 1. This embodiment aims to illustrate the difference between the two.

[0059] In this embodiment, the above-mentioned suction chamber may include a porous material and a film wrapped outside the porous material; wherein, the above-mentioned porous material may preferably be a polyurethane sponge....

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com