Supply of sheet stock material for a dunnage conversion machine and a method of converting same into a dunnage product

A technology of sheet materials and converting machines, applied in the direction of thin material processing, cardboard items, winding strips, etc., can solve difficult and time-consuming problems

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

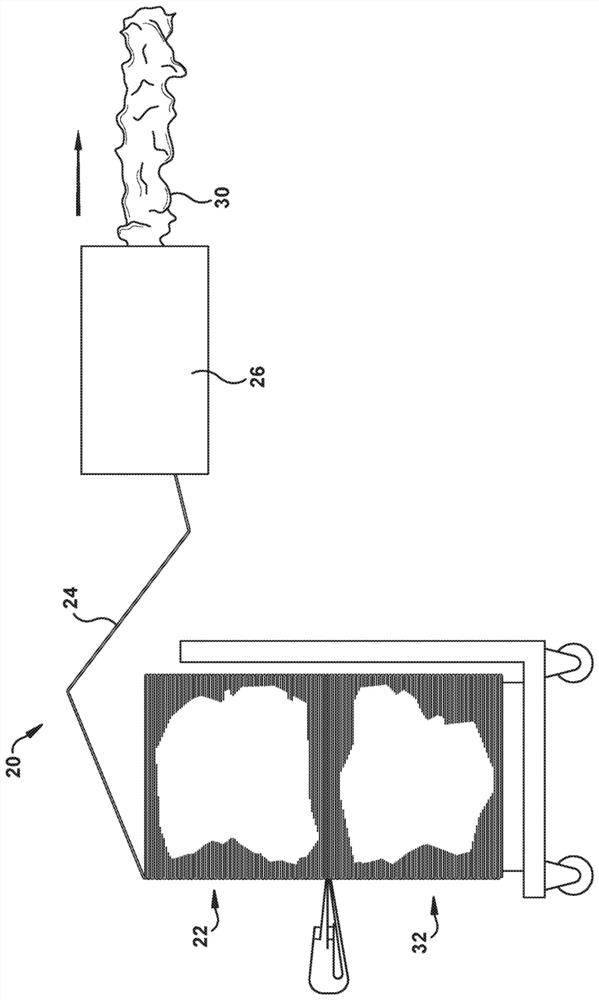

[0053] Referring now to the drawings, first to the attached figure 1 , shows a dunnage conversion system 20 comprising a supply 22 of C-folded sheet material 24 and a dunnage conversion machine 26 of the present invention. The illustrated conversion machine 26 takes sheet material 24 from the supply 22 and converts the sheet material 24 into a dunnage product 30 having a lower density than the unconverted sheet material 24 . Exemplary dunnage conversion machines are disclosed in US Patent Nos. 5,123,889, 5,607,383, and 6,015,374, each of which is incorporated herein by reference.

[0054] The present invention provides a supply 22 of reduced width C-folded sheet material 24 for a dunnage conversion machine 26 that can be easily spliced to another supply 32 of sheet material 24 and discloses the use of A method for splicing together continuous supplies 22 and 32 of such sheet material.

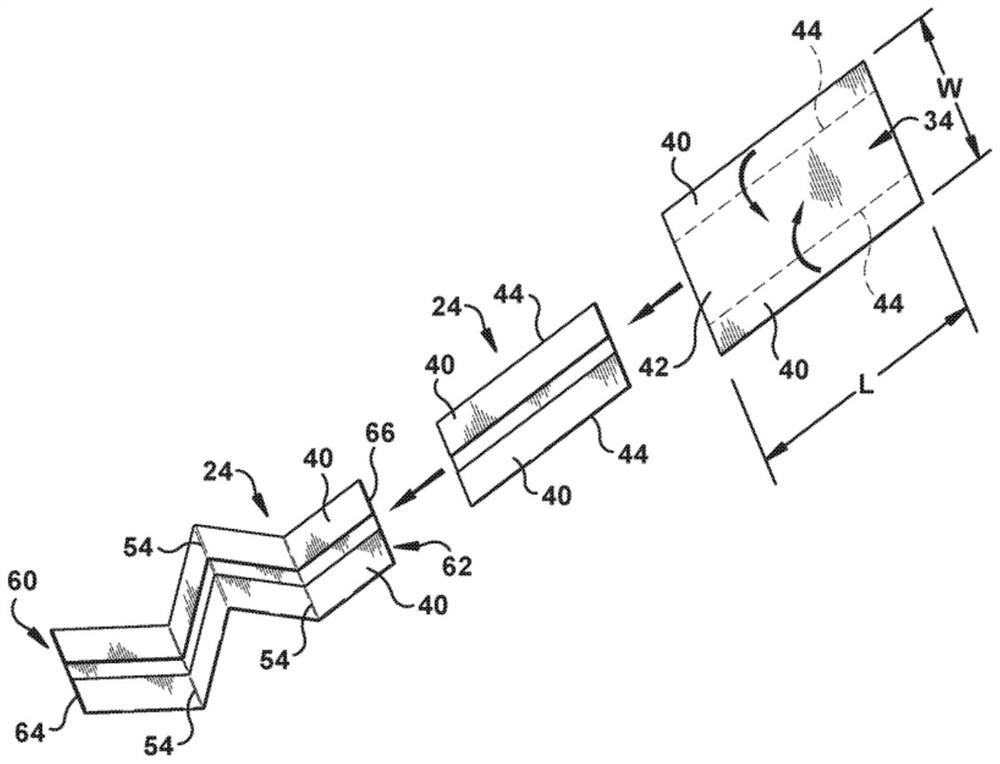

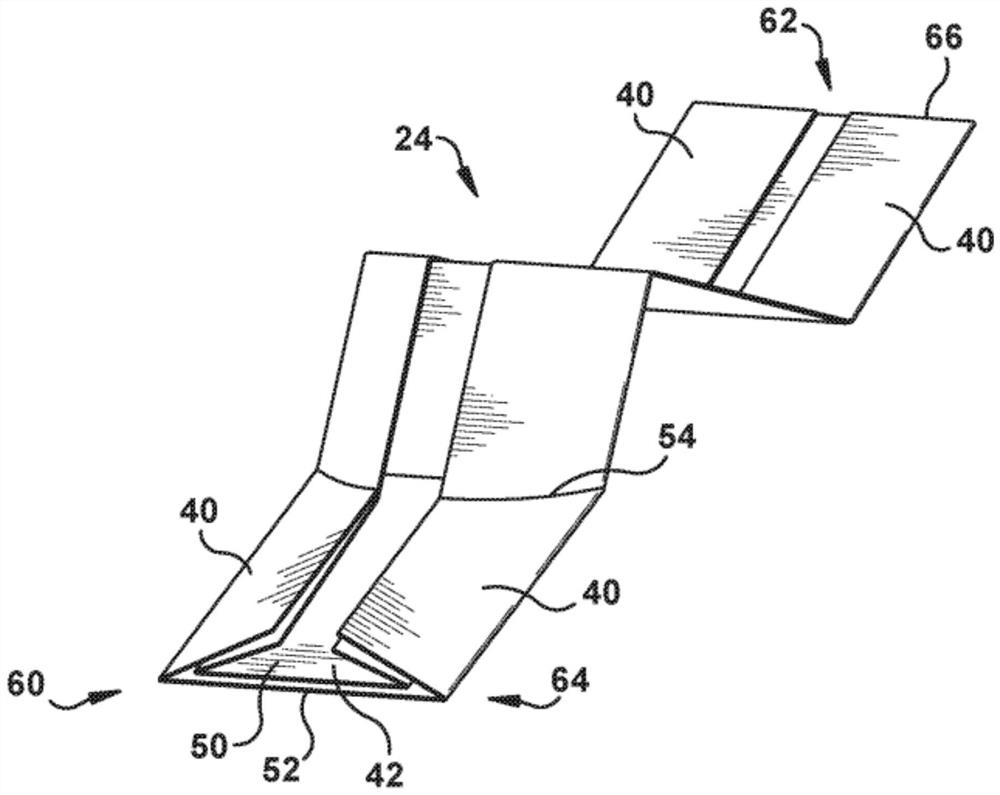

[0055] The C-folded sheet material 24 may comprise paper, such as kraft paper of variou...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com