Polyvinyl chloride-free lipophilic polymer based aromatized plastisol

A plastisol and lyophilic technology, applied in ink, household utensils, applications, etc., can solve problems such as the production of aromatic modeling materials that have not been mentioned

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

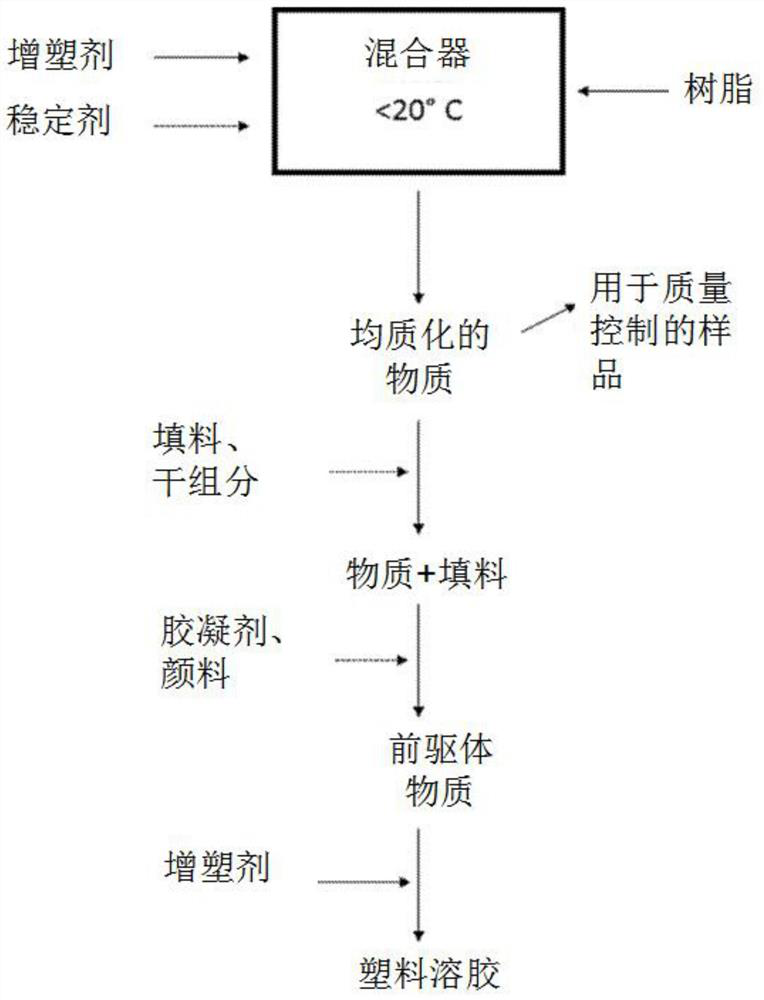

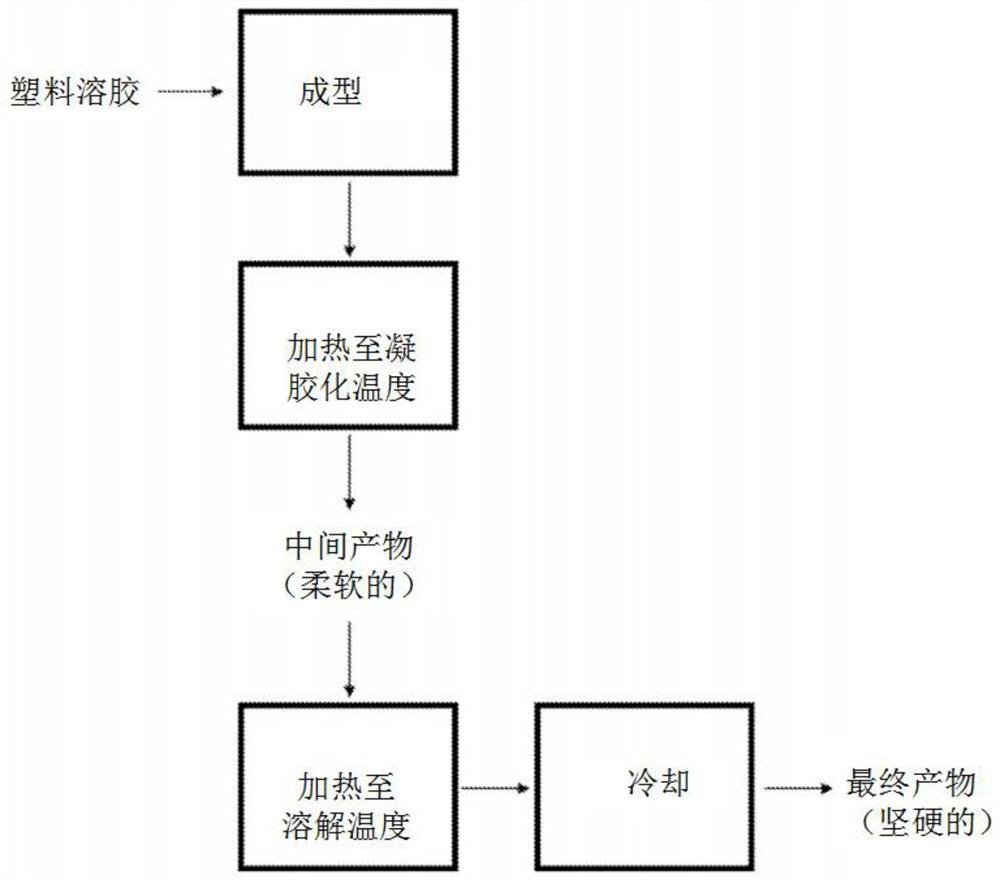

[0059] Suitable polycaprolactone particles of the present invention can be produced according to the method disclosed in US Patent No. 3,632,669. The resulting spray-dried powder is mixed with fillers and pigments, a portion of the plasticizing fragrance material (such as essential oils) is added, followed by the remainder of the fragrance plasticizer premixed with the thixotropic gelling agent. The obtained mass can be molded into blocks or sheets.

[0060] Sufficient shear is required to disperse the plastisol components. At the same time, the duration of the cycle and the shear rate need to be controlled to prevent the generation of excess heat that could prematurely initiate the gelation reaction. It is desirable to keep the temperature below 20°C (eg, by using a cooling jacket, short mixing cycles, and / or limiting mixing rates). Compositions whose viscosity decreases with increasing shear rate can be efficiently prepared at higher speeds. However, this can lead to seve...

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com