Fruit harvesting all-in-one machine

A fruit harvesting and integrated machine technology, which is applied in the direction of picking machines, harvesters, agricultural machinery and implements, etc., can solve the problems of inconvenient use, unadjustable vibration strength and amplitude of trees, lack of fruit harvesting integrated machines, etc., and achieve improvement High working efficiency and harvesting efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

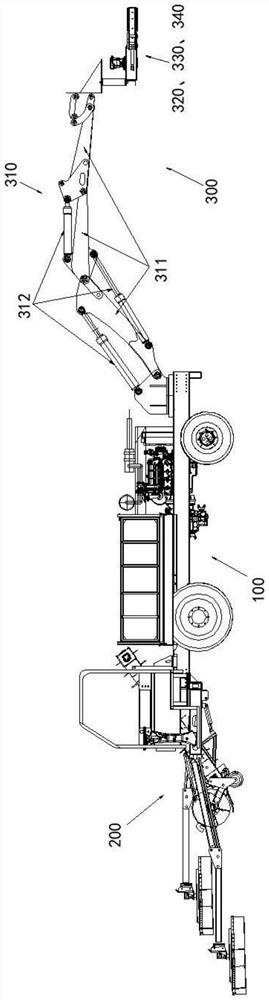

[0027] Such as figure 1 As shown, the integrated fruit harvesting machine of this embodiment includes a mobile platform 100, a pick-up mechanism 200 and a clamp vibration mechanism 300;

[0028] The pick-up mechanism 200 and the clamp vibration mechanism 300 are all installed on the mobile platform 100, and structures such as hydraulic pumps, transmission systems and cabs are also installed on the mobile platform 100; the pick-up mechanism 200 is used to pick up fruits, branches and Leaves and fruits are separated from them. The specific composition and working principle of the picking mechanism 200 have been disclosed in the patent "A Fruit Picking Machine";

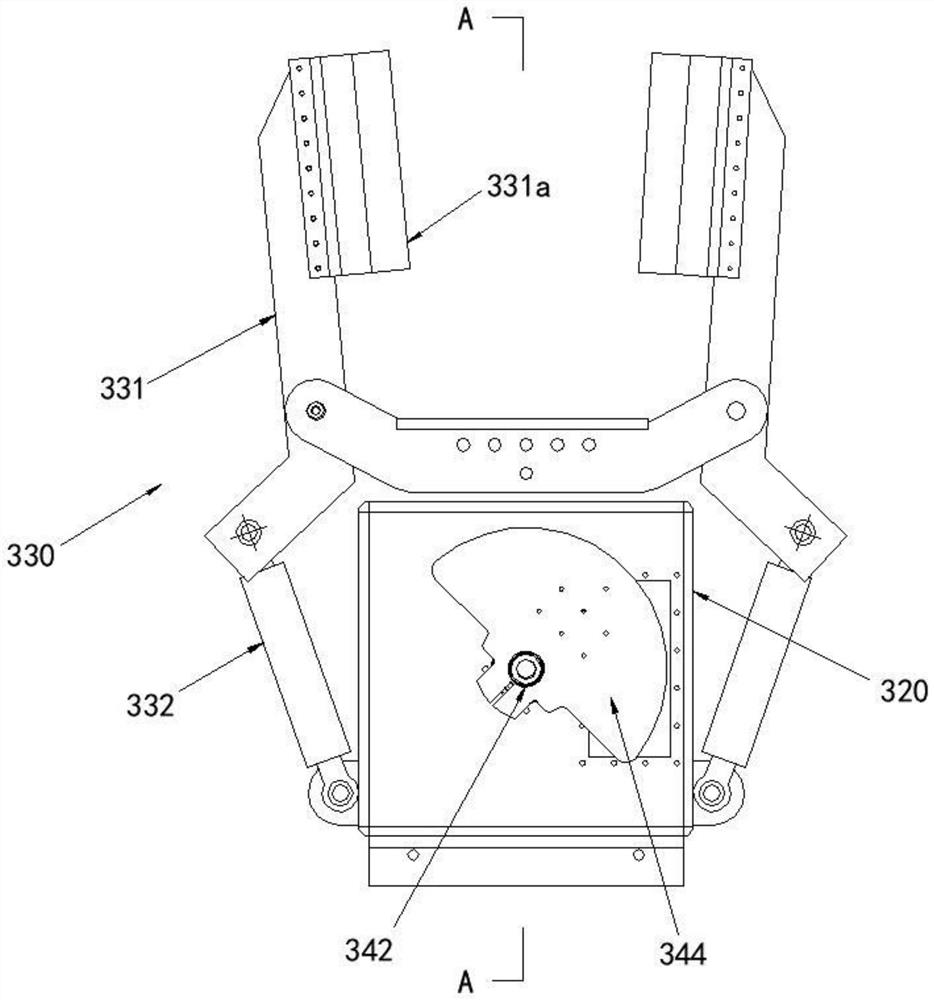

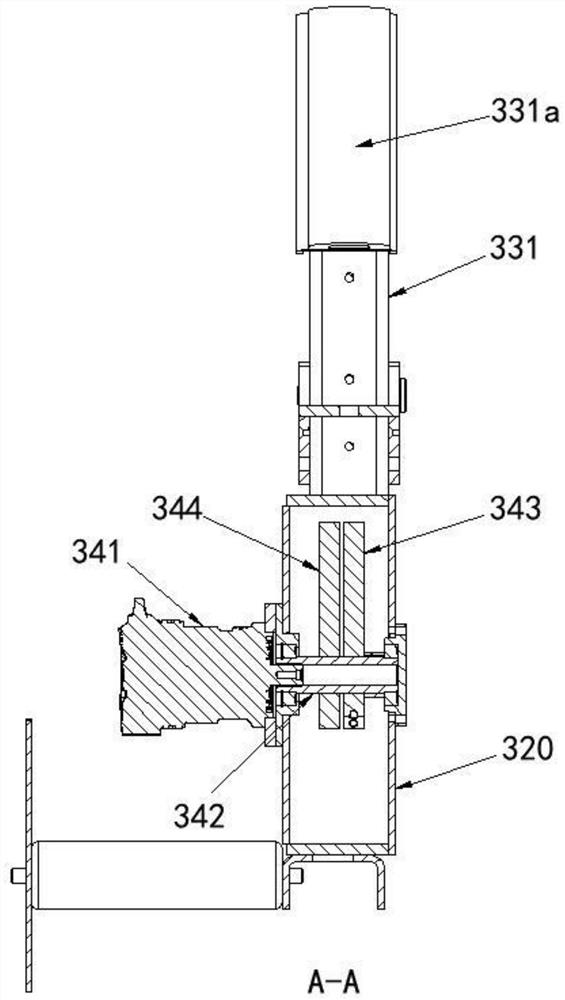

[0029] The holding clamp vibration mechanism 300 includes an adjusting arm assembly 310, a frame 320, an holding clamp assembly 330, and a vibrating assembly 340. The adjusting arm assembly 310 includes three booms 311 and three third hydraulic cylinders 312, and the three booms 311 are hinged in turn. The three third ...

Embodiment 2

[0039] Such as Figure 4 to Figure 7 As shown, this embodiment is basically the same as Embodiment 1, except that the vibration assembly 340 is the only difference. In this embodiment, the second eccentric block 344 is no longer locked by a locking lever, and the vibration assembly 340 also includes the second rotating shaft 345, pin shaft 346, first hydraulic cylinder 347 and shaft coupling 348; The inside of the first rotating shaft 342 is hollow and the surface of the first rotating shaft 342 is provided with such as Figure 8 As shown in the spiral groove 342a, the second eccentric block 344 is provided with a radial pin hole, the second rotating shaft 345 is located inside the first rotating shaft 342 and is coaxial with the first rotating shaft 342, and the pin shaft 346 passes through the second eccentric block The pin hole on the 344 and the spiral groove 342a on the surface of the first rotating shaft 342 are connected with the second rotating shaft 345; the coupling ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com