Adjustable manual lifting table

An adjustable technology for lifting tables, applied in the field of lifting tables, can solve the problems of slow adjustment speed, easy to rust, and danger, and achieve the effect of saving time and effort in the operation process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

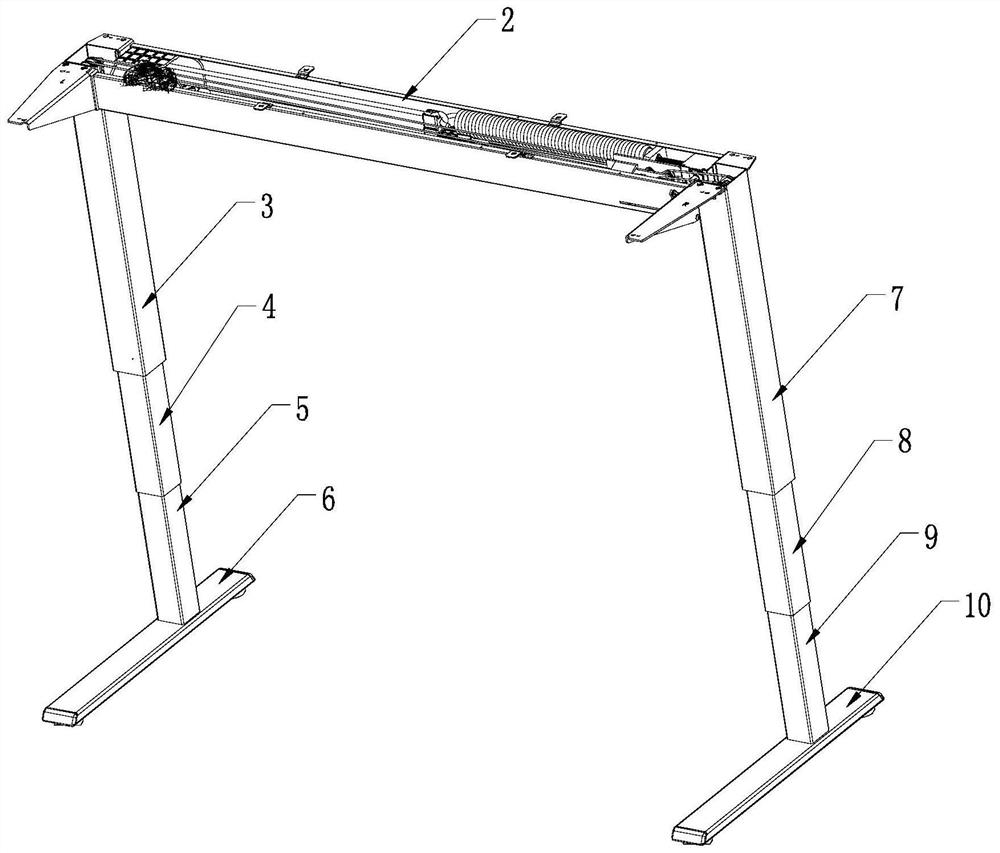

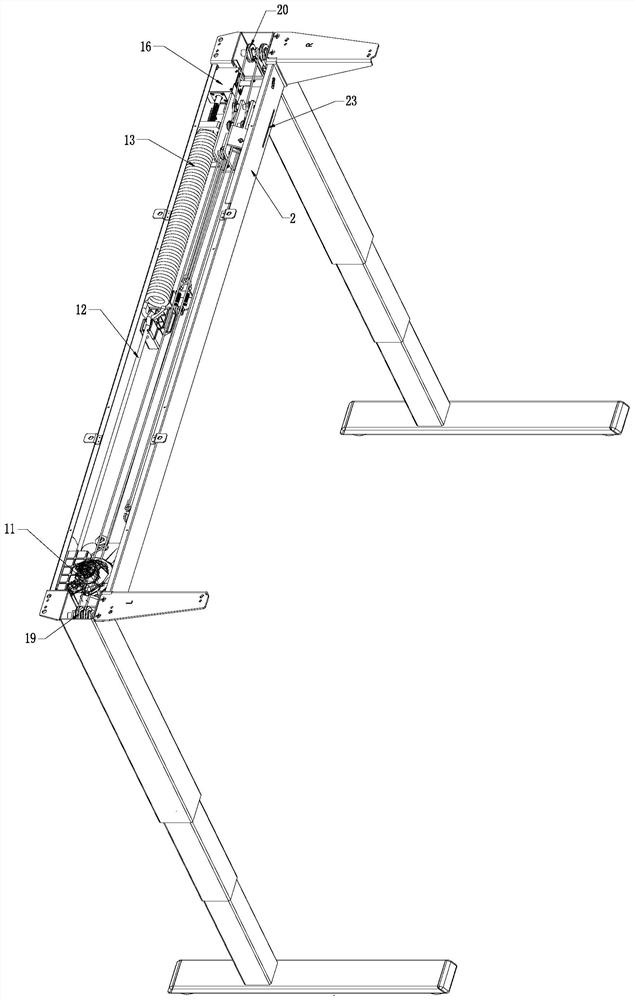

[0046] The present invention will be further described below according to the accompanying drawings.

[0047] Such as Figure 1 to Figure 24As shown, the upper end of the crossbeam 2 is connected to the work surface 1, and the left and right sides of the lower end of the crossbeam 2 are respectively connected to the left lifting table leg assembly and the right lifting table leg assembly; Connect one end of the cam disc drive rope 12, the other end of the cam disc drive cord 12 is connected to the cam disc assembly 11; the other end of the driving spring 13 is connected to the spring tension regulator 16; 21 and one end of the auxiliary steel rope 22, the other end of the active steel rope 21 is divided into two routes, respectively connected to one end of the left active rope 17 and the right active rope 18, and the other end of the auxiliary steel rope 22 is divided into two routes, respectively connected to the left auxiliary rope 14 and the right auxiliary rope 15; the le...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com