Bearing bush inner wall polishing device for high-end manufacturing

It is a high-end technology in the bearing bush, which is used in grinding drive devices, grinding/polishing safety devices, manufacturing tools, etc. It can solve problems such as affecting the grinding effect, spreading of the bushing, and inconvenience in fixing, so as to increase the working strength and prevent The effect of falling debris and easy cleaning

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

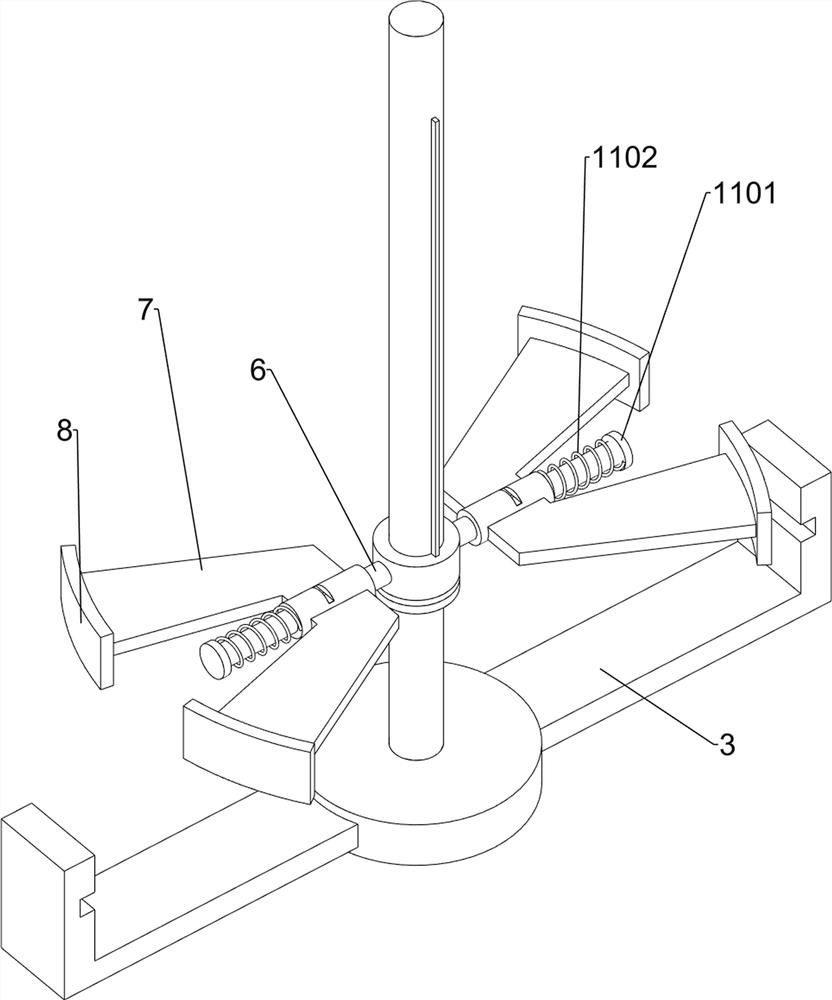

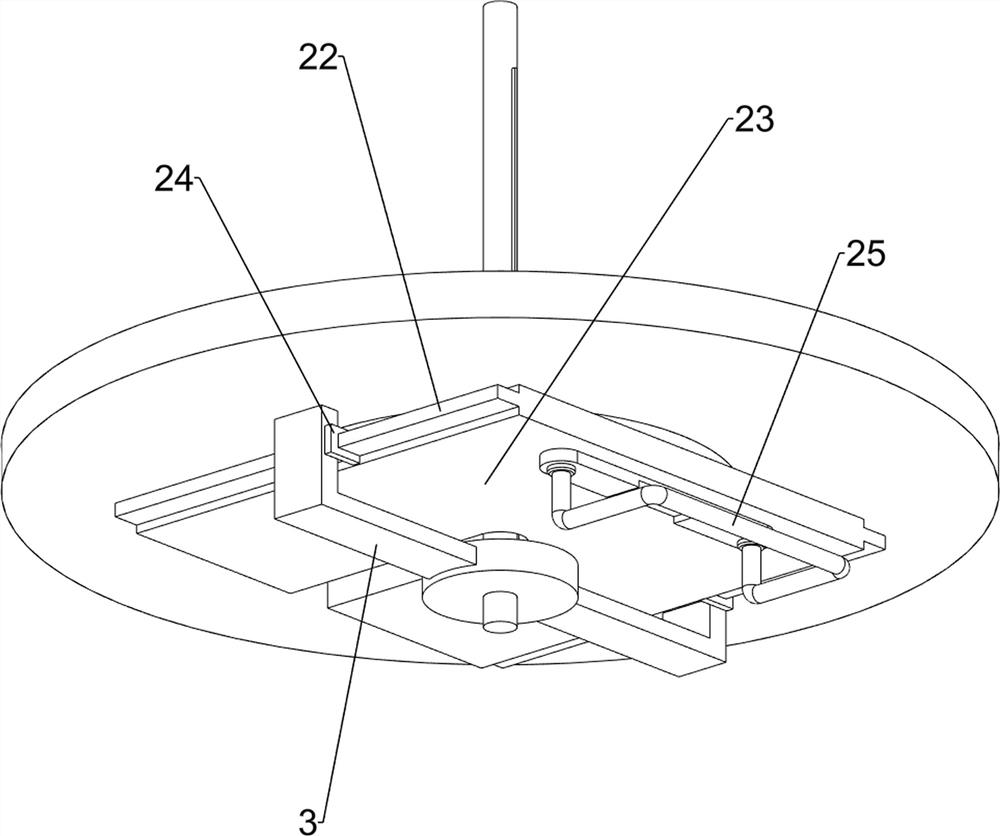

[0026] Such as figure 1 , figure 2 and Figure 6 As shown, a high-end manufacturing bearing inner wall grinding device includes a first bracket 1, a placement plate 2, a first bearing seat 3, a second bearing seat 4, a straight shaft 5, a guide rod 6, a first slider 7, Grinding block 8, second bracket 9, servo motor 10, extruding mechanism 11 and clamping mechanism 12, the first bracket 1 is provided with a placement plate 2, the bottom of the placement plate 2 is provided with a first bearing seat 3, and the top of the placement plate 2 A second bearing seat 4 is provided, and a straight shaft 5 is rotatably arranged between the first bearing seat 3 and the second bearing seat 4, and a guide rod 6 is symmetrically arranged on the straight shaft 5 through a sliding sleeve. The sliding type is provided with a first slider 7, and the front and rear of the two first sliders 7 are provided with a polishing block 8, and the bottom of the placement plate 2 is provided with a seco...

Embodiment 2

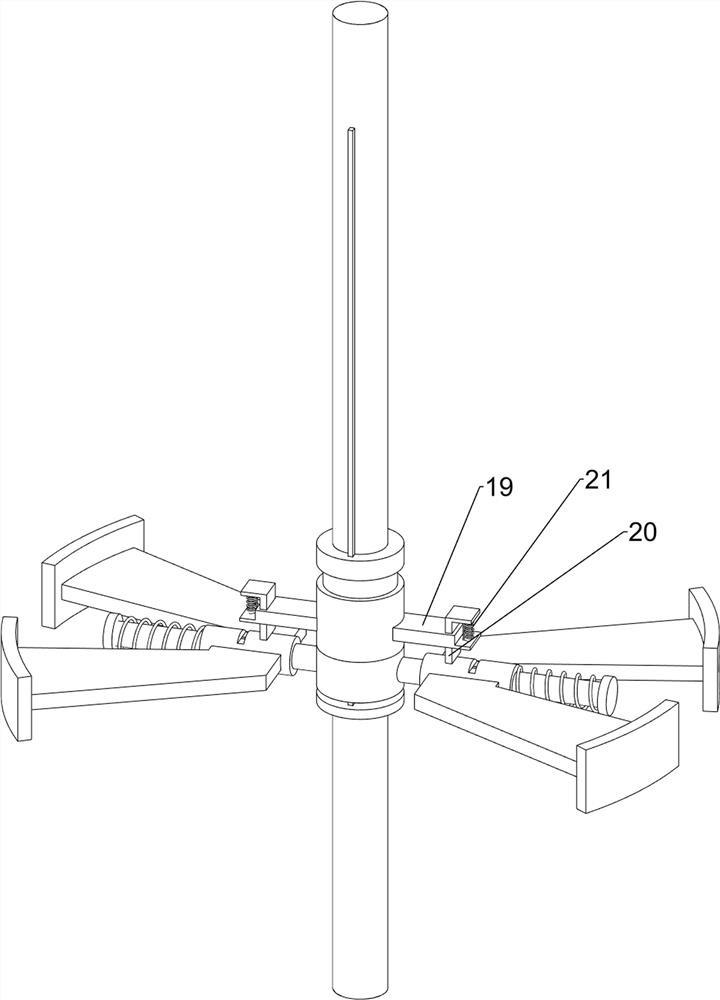

[0029] Such as figure 2 and image 3 As shown, on the basis of Embodiment 1, the extrusion mechanism 11 includes a first fixed block 1101 and a first elastic member 1102, the two guide rods 6 are provided with a first fixed block 1101 at the opposite end, and the two second A first elastic member 1102 is disposed between one side of a fixed block 1101 and one side of the two first sliders 7 .

[0030] When it is necessary to grind the inner wall of the tile shaft, the staff pushes the first slider 7 to slide toward each other on the guide rod 6, the first elastic member 1102 is stretched, and the grinding block 8 moves toward each other, and then the staff places the tile shaft On the placement plate 2, after the placement is completed, the staff rotates the clamping mechanism 12 and moves in opposite directions to clamp the tile shaft. After the tile shaft is clamped, the staff releases the first slider 7, and the first elastic member 1102 resets Drive the first slider 7 t...

Embodiment 3

[0034] Such as Figure 4 , Figure 5 and Figure 6 As shown, it also includes a slide bar 13, a second fixed block 14, a rotating shaft sleeve 15 and a second handle 16, the second bearing seat 4 is provided with a slide bar 13 in a symmetrical sliding manner, and the bottom ends of the two slide bars 13 are all provided with The second fixed block 14 is provided with a rotating shaft sleeve 15 slidingly on the straight shaft 5, and the opposite sides of the two second fixed blocks 14 are connected with the left and right sides of the rotating shaft sleeve 15, and the bottom of the rotating shaft sleeve 15 is connected with the upper part of the sliding sleeve. A second handle 16 is arranged between the top ends of the rods 13 .

[0035] When the tile shaft needs to be polished to different heights, the staff pulls the second handle 16 to drive the slide bar 13 to slide upward on the second bearing seat 4, and the slide bar 13 slides upward to pass through the second fixed b...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com