Oil painting brush cleaning device

A technology for cleaning devices and oil paint brushes, which can be used in decorative art and painting tools to solve the problems of brush hair falling off and uneven painting layers, and achieve the effect of preventing uneven layers

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0028] Figure 1 to Figure 6 Shown:

[0029] The invention provides an oil paint brush cleaning device,

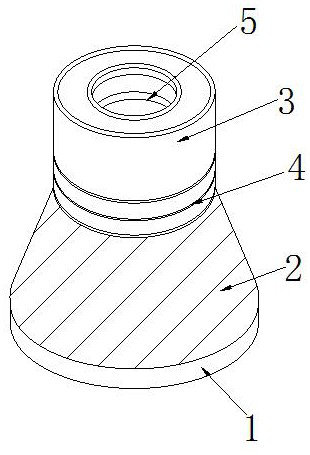

[0030] Its structure includes a positioning seat 1, a cleaning cylinder 2, a positioning channel 3, a connecting shaft 4, and an insertion end 5. 4 is embedded in the lower end of the positioning channel 3, and the insertion end 5 is integrated with the positioning channel 3.

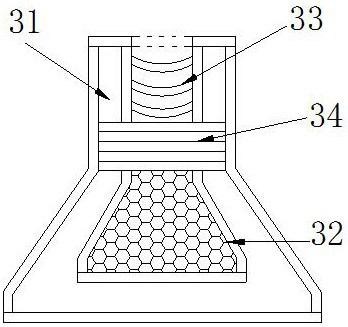

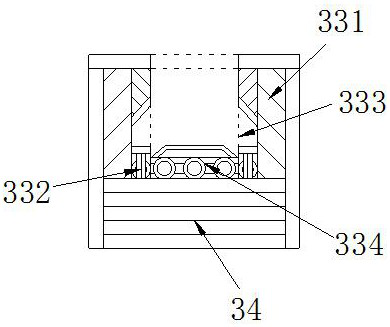

[0031] The positioning passage 3 is provided with an installation groove 31, a partition dish 32, an insertion passage 33, and a balance weight 34. The installation groove 31 communicates with the partition dish 32, and the insertion passage 33 is installed on the upper end of the partition dish 32. The balance The block 34 is embedded in the lower end of the insertion channel 33. The balance block 34 is in a solid state and forms a cuboid shape. The balance block 34 can be effectively fixed on the upper end of the partition dish 32 through its solid state and cuboid shape and is stable. Insert c...

Embodiment 2

[0039] Figure 7 to Figure 9 Shown:

[0040] The invention provides an oil paint brush cleaning device,

[0041] Its structure comprises that described partition dish 32 is provided with hole 321, chassis 322, partition net 323, disassembly block 324, and described hole 321 communicates with chassis 322, and described partition net 323 is installed on the upper end of chassis 322, and described disassembly block 324 Embedded on both sides of the partition net 323, the disassembly block 324 is provided with one piece on both sides of the lower end of the partition net 323. The disassembly block 324 can effectively play a role in the subsequent disassembly and maintenance of the partition net 323 through its own quantity. Shortcut effect.

[0042] Wherein, the chassis 322 is provided with an outer frame c1, a groove c2, a concentration block c3, and a guide block c4. The outer frame c1 and the groove c2 are integrated, and the concentration block c3 is embedded in the groove c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com