Machining platform for high-rise steel structure machining and machining method of machining platform

A technology for processing platforms and steel structures, applied in the direction of manufacturing tools, lifting devices, electrical components, etc., can solve problems such as inconvenience, and achieve the effect of preventing uneven bending, reducing installation steps and use costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

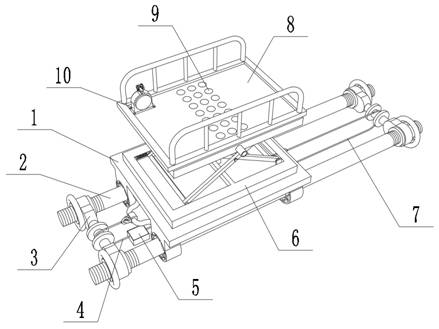

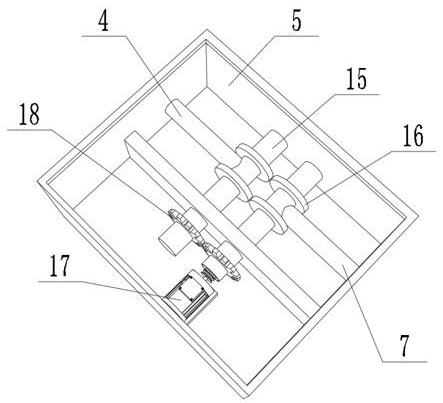

[0042] A processing platform for high-rise steel structure processing, such as figure 1 , 2 , 4 and 5, including a mobile platform 1 and two steel pipes 2; the four corners of the outer wall of the bottom of the mobile platform 1 are respectively welded with a sliding frame 14, and the inner wall on one side of the sliding frame 14 is provided with a sliding opening 28, and the sliding opening 28 is internally provided with Rolling mechanism, each steel pipe 2 is slidably connected to the inside of the two sliding ports 28 through the rolling mechanism, and the two ends of the two steel pipes 2 are respectively welded with threaded rods 19, and the outer walls of the two adjacent threaded rods 19 pass through the mounting holes provided on them respectively. The component is fixed with a limit rod 21, and the outer wall of the limit rod 21 is clamped with two limit plates 22, and the outer walls of two adjacent sliding frames 14 are fixed with the same connecting frame 27, and...

Embodiment 2

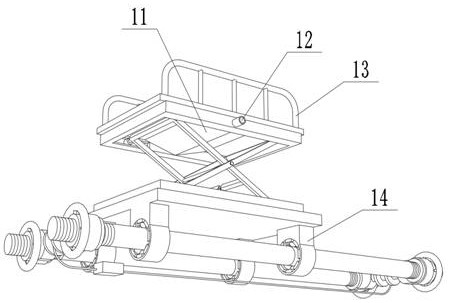

[0048] A processing platform for high-rise steel structure processing, such as figure 1 and 2 As shown, in order to be able to adjust the height; the present embodiment makes the following improvements on the basis of Embodiment 1: the outer wall of the top of the mobile platform 1 is provided with a lifting platform 6, the outer wall of the top of the lifting platform 6 is provided with a working platform 8, and the top of the working platform 8 There are more than two collection ports 9 on the outer wall, a funnel 11 is fixed on the outer wall at the bottom of the working platform 8, the funnel 11 is connected to the collecting port 9, a sewage pipe 12 is clipped on the outer wall of one side of the funnel 11, and the two sides of the outer wall on the top of the working platform 8 are respectively provided Guardrail 13 is arranged, and the outer wall of working platform 8 top is fixed with fixed frame 10 by bolt, and fixed frame 10 interior is provided with adjusting mechan...

Embodiment 3

[0052] A processing method for a processing platform for high-rise steel structure processing, comprising the following steps:

[0053] S1: Pass the two steel pipes 2 through the four corresponding sliding frames 14 in turn, the rotating ball 25 rolls on the inner wall of one side of the groove, the rotating ball 25 is matched with the round cover 30, and under the action of the adjusting spring 29, Push the rotating ball 25 into contact with the steel pipe 2 to prevent the steel pipe 2 from being bent and uneven, which may cause the phenomenon of movement jamming;

[0054] S2: Weld the threaded rod 19 at both ends of the steel pipe 2, then hold the runner 20, and screw the rotating sleeve 23 on the threaded rod 19, thereby completing the connection of the two steel pipes 2;

[0055] S3: Then use rope one 4 and rope two 7 to connect two hanging rings 26, rope one 4 and rope two 7 are respectively located between the two corresponding limit plates 22, rope one 4 and rope two 7 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com