Hole lamp processing technology

A processing technology and hole lamp technology, used in lighting and heating equipment, lighting devices, light sources, etc., can solve the problems of uneven surface of lamp sockets, affecting the lighting effect of LED lights, etc., to prevent unevenness and prevent drill chips from falling. , the effect of narrowing the gap

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

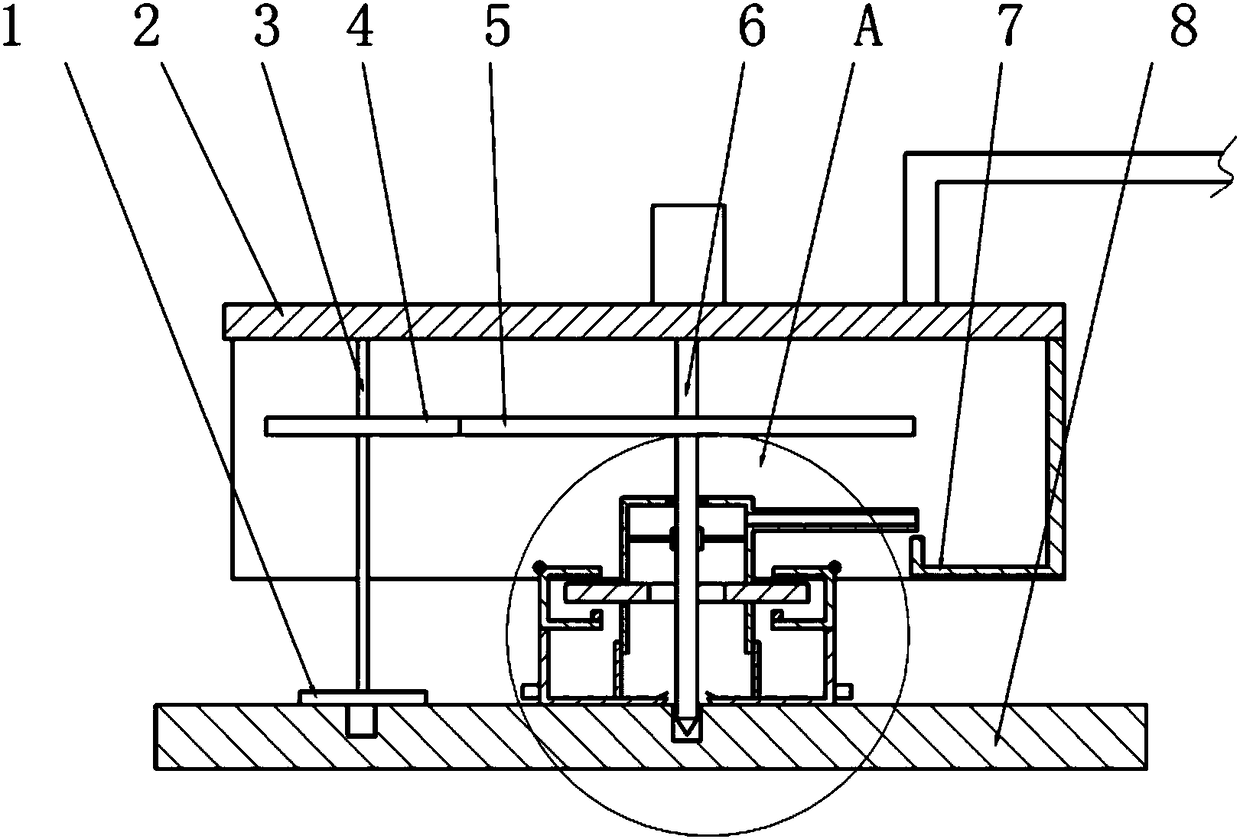

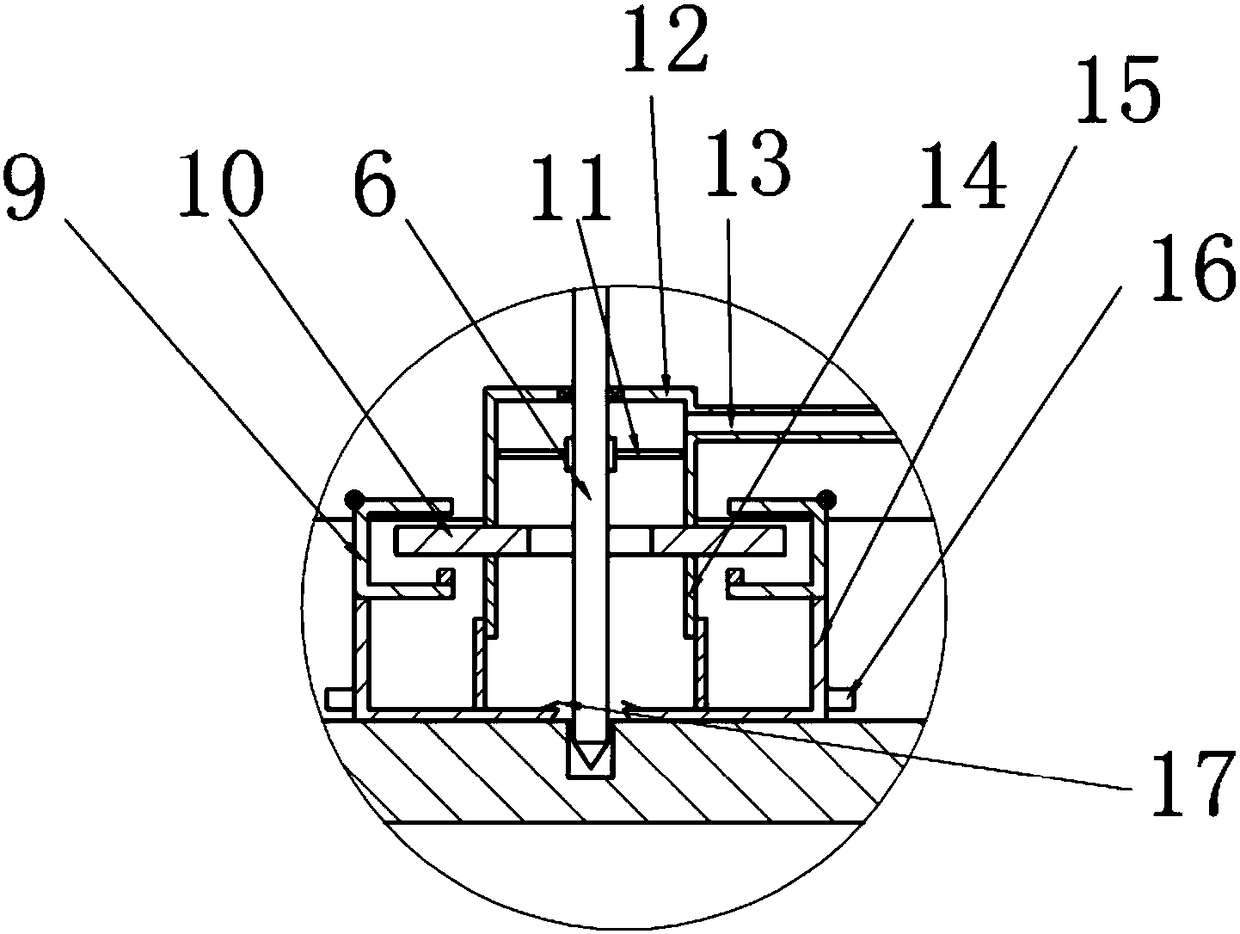

[0026] Example: such as figure 1 and figure 2 As shown, the drilling machine used in this embodiment includes a frame 2 on which a motor-driven drill 6 is rotatably connected. A cylindrical chip suction cover 12 is rotatably connected to the drill bit 6 , and the chip suction cover 12 is fixedly connected to the frame 2 . The bottom of the dust suction cover 12 is fixedly connected with a fixed plate 10, and the bottom of the fixed plate 10 is fixedly connected with a telescopic cover 14 that can be stretched up and down. The fixed plate 10 is provided with a through hole, and the drill bit 6 passes through the through hole and the telescopic sleeve in sequence.

[0027] The two sides of fixed plate 10 are provided with rotatable clamping block 9, and clamping block 9 has opening, and fixed plate 10 both sides are positioned at opening, and clamping block 9 is rotatably connected on the frame 2, and the bottom of clamping block 9 is fixedly connected with cross-sectional sh...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com