Acrylic material for mirror surface as well as preparation method and use method of acrylic material

A technology of acrylic and raw materials, applied in the direction of chemical instruments and methods, layered products, metal layered products, etc., can solve the problems of mirror image deformation, non-compliance with the requirements of mirror acrylic plates, etc., and achieve the effect of preventing unevenness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

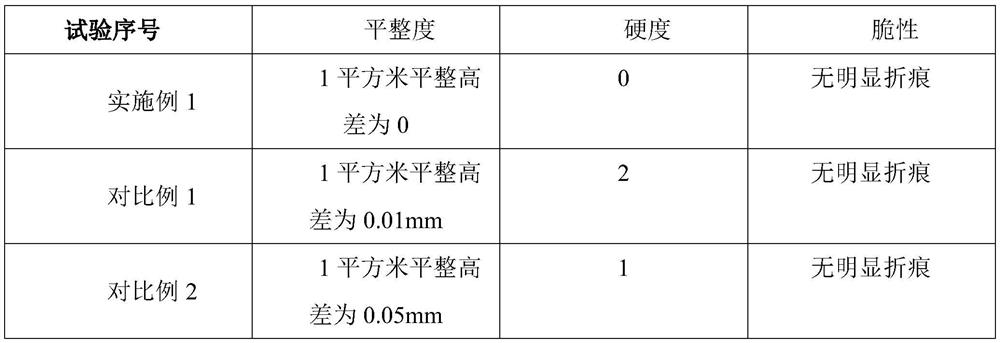

Examples

Embodiment 1

[0039] A kind of acrylic material for mirror disclosed in this embodiment comprises the following raw materials, polymethyl methacrylate 50%, epoxy silane 20%, maleimide 10%, α-methacrylic acid 5%, initiator 0.1%, cross-linking agent 0.2%.

[0040] In this embodiment, the initiator is selected from azobisisocarbonitrile.

[0041] In this embodiment, the crosslinking agent is selected from ethylene glycol dimethacrylate, ethylene glycol dimethacrylate and 2,2-dimethyl-1,3-propanediol dimethacrylate mixtures in esters.

[0042] The preparation method of the acrylic material for the above-mentioned mirror surface comprises the following steps:

[0043] S1: Put methyl methacrylate, epoxy silane, maleimide, α-methacrylic acid, initiator and cross-linking agent into the reactor and pass nitrogen to remove oxygen, then pass hot water at 70°C to continue Reacted for 15 minutes to obtain a solid content of 40% methyl methacrylate prepolymer;

[0044] S2: Pour the methyl methacrylat...

Embodiment 2

[0054] A kind of acrylic material for mirror disclosed in this embodiment comprises the following raw materials, polymethyl methacrylate 60%, epoxy silane 30%, maleimide 15%, α-methacrylic acid 6%, initiator 1%, crosslinking agent 2%.

[0055] In this embodiment, the initiator is selected from azobisisoheptanonitrile.

[0056] In this embodiment, the crosslinking agent is selected from a mixture of ethylene glycol dimethacrylate and 2,2-dimethyl-1,3-propanediol dimethacrylate.

[0057] The preparation method of the acrylic material for the above-mentioned mirror surface comprises the following steps:

[0058] S1: Put methyl methacrylate, epoxy silane, maleimide, α-methacrylic acid, initiator and cross-linking agent into the reactor and pass nitrogen to remove oxygen, then pass hot water at 80°C to continue Reaction 0min, obtaining solid content is 50% methyl methacrylate prepolymer;

[0059] S2: Pour the methyl methacrylate prepolymer prepared in S1 into a flat mold, then p...

Embodiment 3

[0069] An acrylic material for a mirror disclosed in this embodiment comprises the following raw materials: 55% polymethyl methacrylate, 25% epoxy silane, 12% maleimide, 5.5% α-methacrylic acid, initiator 0.9%, crosslinking agent 1%.

[0070] In this embodiment, the initiator is selected from a mixture of azobisisoheptanonitrile and azobisisoheptanonitrile.

[0071] In this embodiment, the crosslinking agent is selected from ethylene glycol dimethacrylate.

[0072] The preparation method of the acrylic material for the above-mentioned mirror surface comprises the following steps:

[0073] S1: Put methyl methacrylate, epoxy silane, maleimide, α-methacrylic acid, initiator and cross-linking agent into the reactor and pass nitrogen to remove oxygen, then pass hot water at 75°C to continue Reaction 20min, obtain solid content and be 45% methyl methacrylate prepolymer;

[0074] S2: Pour the methyl methacrylate prepolymer prepared in S1 into a flat mold, then press mold and cool ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com