High-speed elevator tensioning device

A tensioning device, high-speed elevator technology, applied in transportation and packaging, springs/shock absorbers, elevators, etc., can solve the problems of excessive wire rope swing, affecting the normal operation of the speed limiter, and vibration of the tensioning device. Avoid excessive swing effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The present invention is further illustrated in conjunction with the accompanying drawings and specific embodiments.

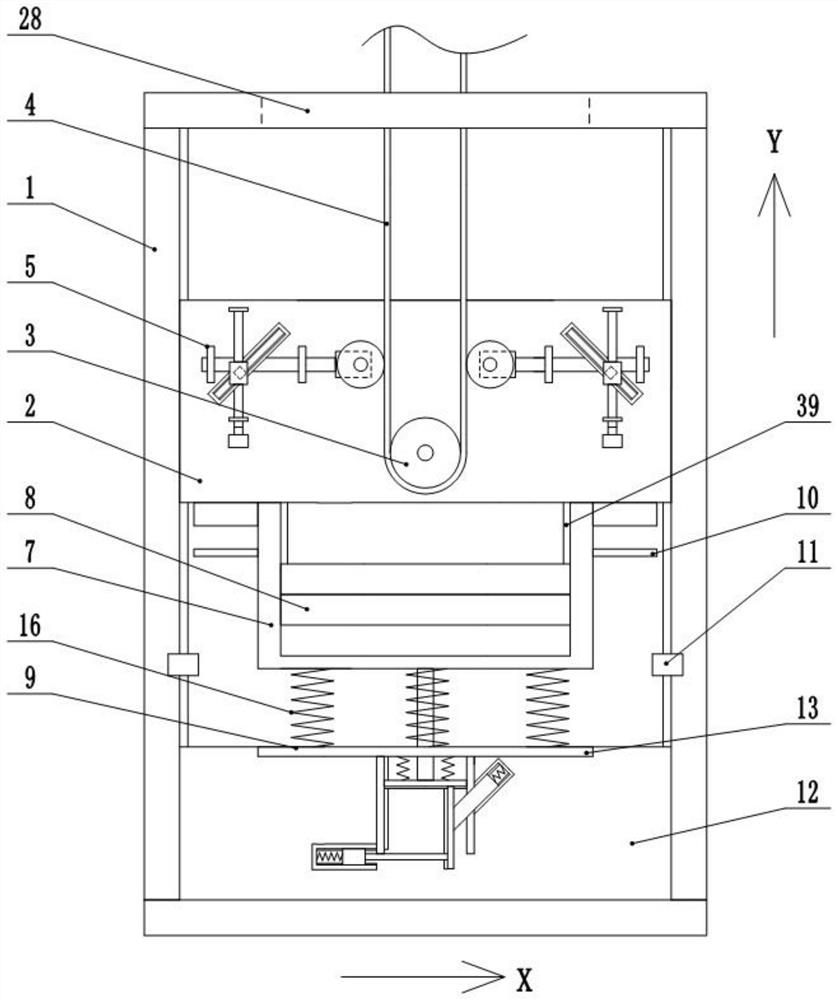

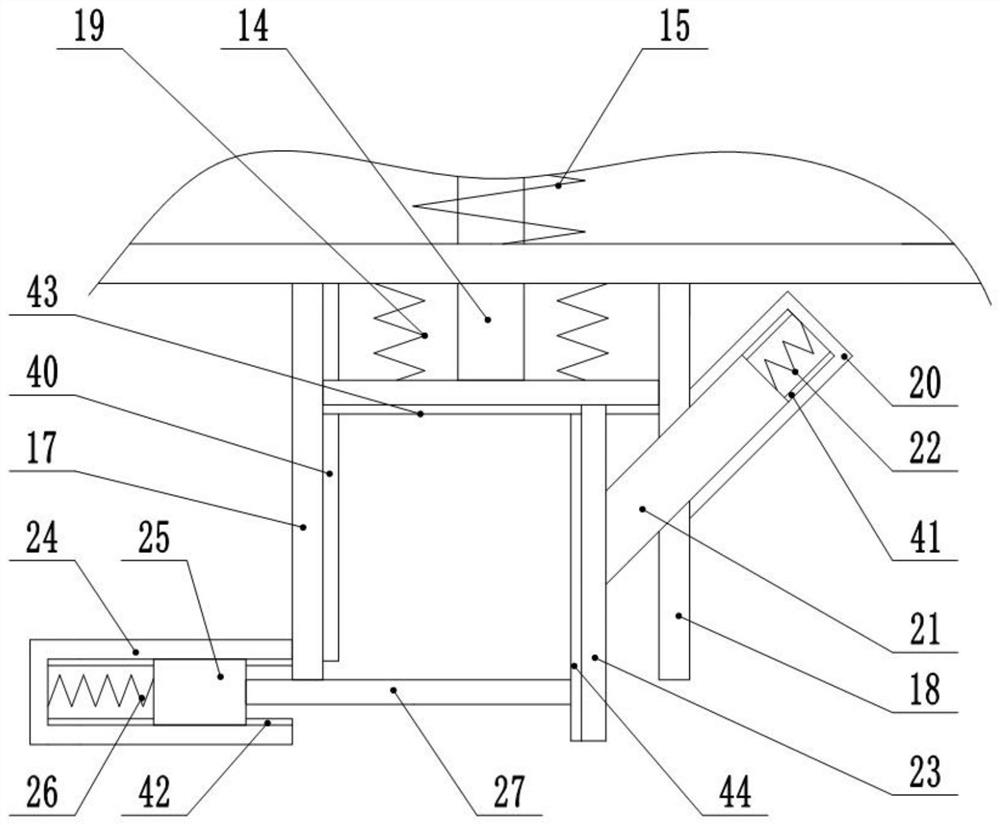

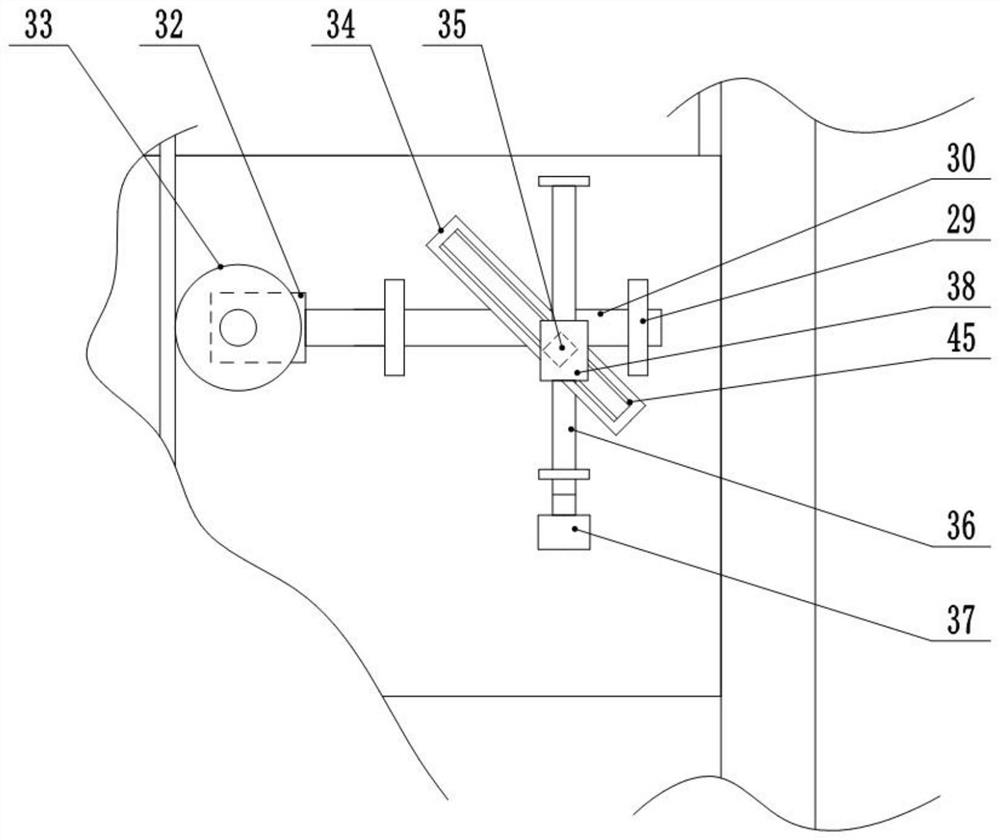

[0026] A high-speed elevator tensioning device, including a frame 1, a translational plate 2 that is moved within the outer frame 1, and is rotatably mounted on the translational plate 2 by the rolling bearing. 3, bypassing the tensioner 3 and tensioned Wheel 3 frictionally driven wire rope 4, wire rope 4 passes through the outer frame 1, mounted on the tension wheel 3 and is located on the pair of adjustment assembly 5 on the left and right tensioning wheel 3, and is mounted on the bottom of the translation plate 2 by the bolt. Box 7, movingly mounted a plurality of kings 8 on the inner frame 7, mounted on the shock absorbing assembly 9 at the bottom of the outer frame 1, and the inside of the inner frame 7 is mounted on both sides of the left and right side, and the outer frame 1 is left. A proximity switch 11 is installed on the side.

[0027] The dampin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com