Valveless piezoelectric pump with separated driving structure and flow resistance structure and working method of valveless piezoelectric pump

A valveless piezoelectric pump and drive structure technology, which is applied to the components of pumping devices for elastic fluids, pumps with flexible working elements, pumps, etc. Problems such as poor fluidity and limited difference in flow resistance can achieve the effects of easy processing, strong reverse flow resistance and improved cooling performance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0037] Specific embodiments of the present invention have been described above. It should be understood that the present invention is not limited to the specific embodiments described above, and those skilled in the art may make various changes or modifications within the scope of the claims, which do not affect the essence of the present invention.

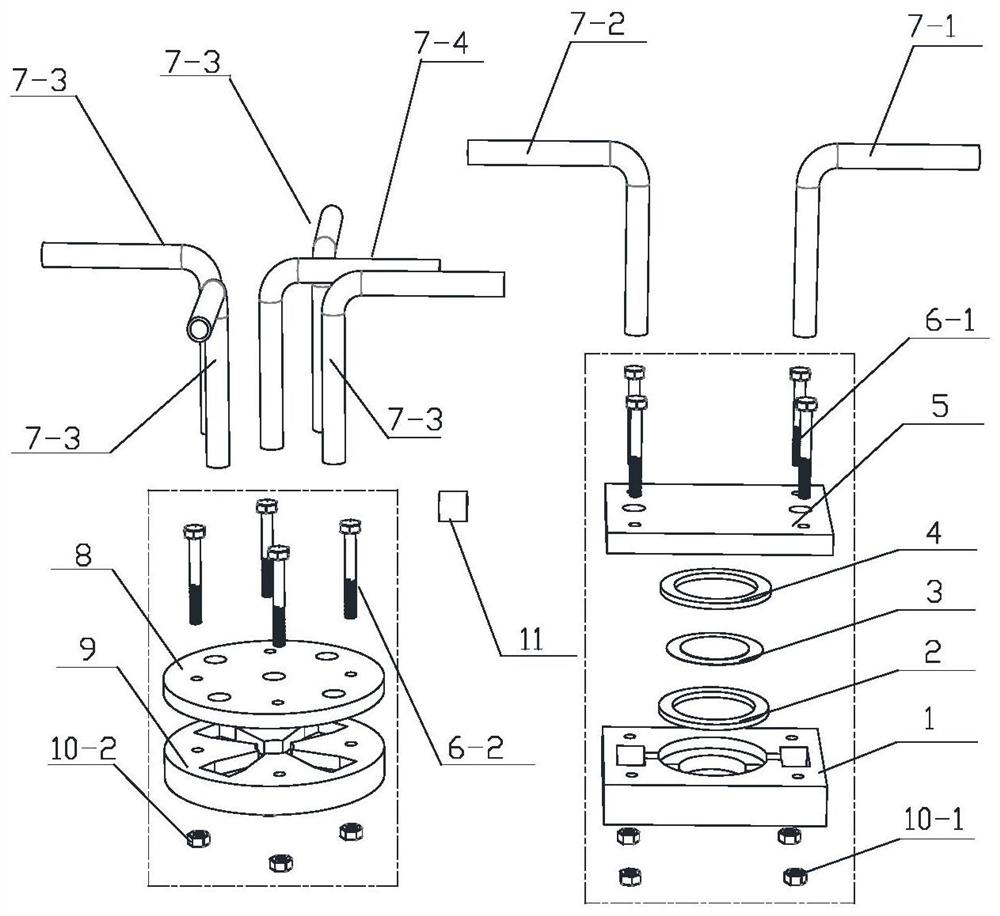

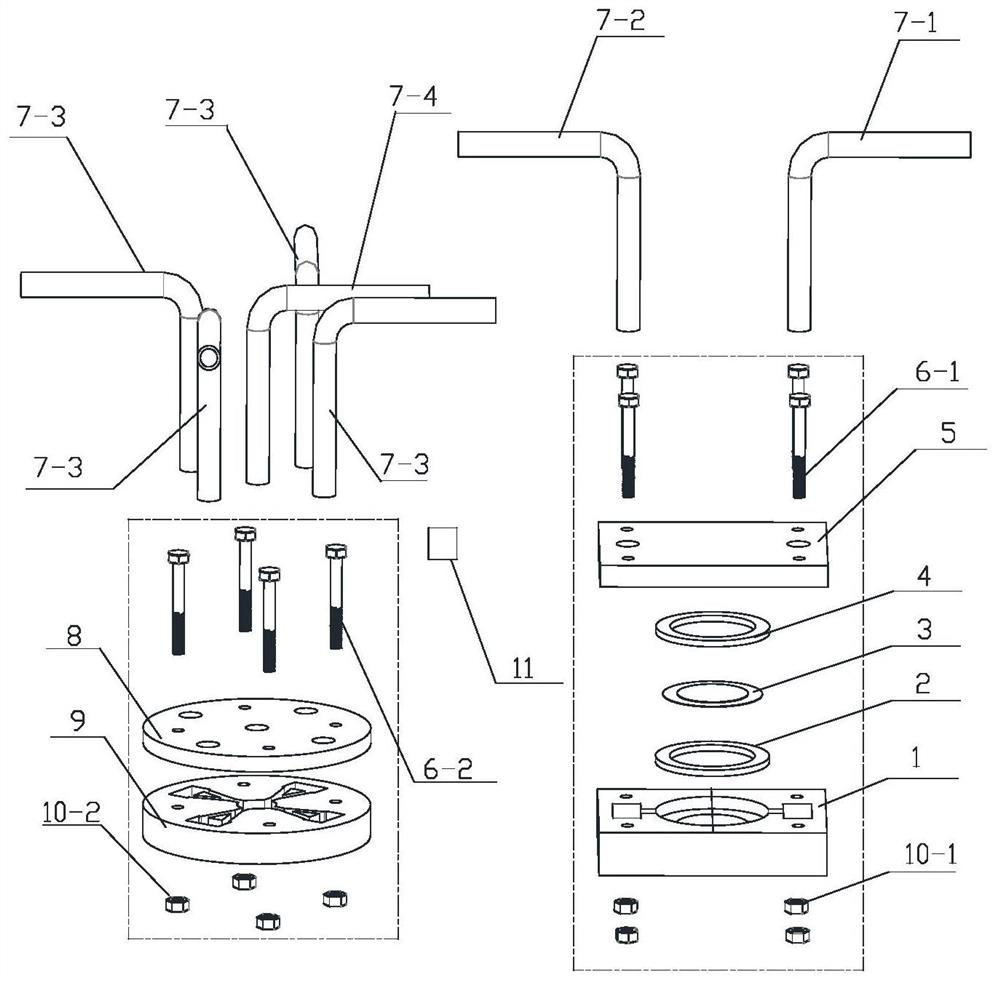

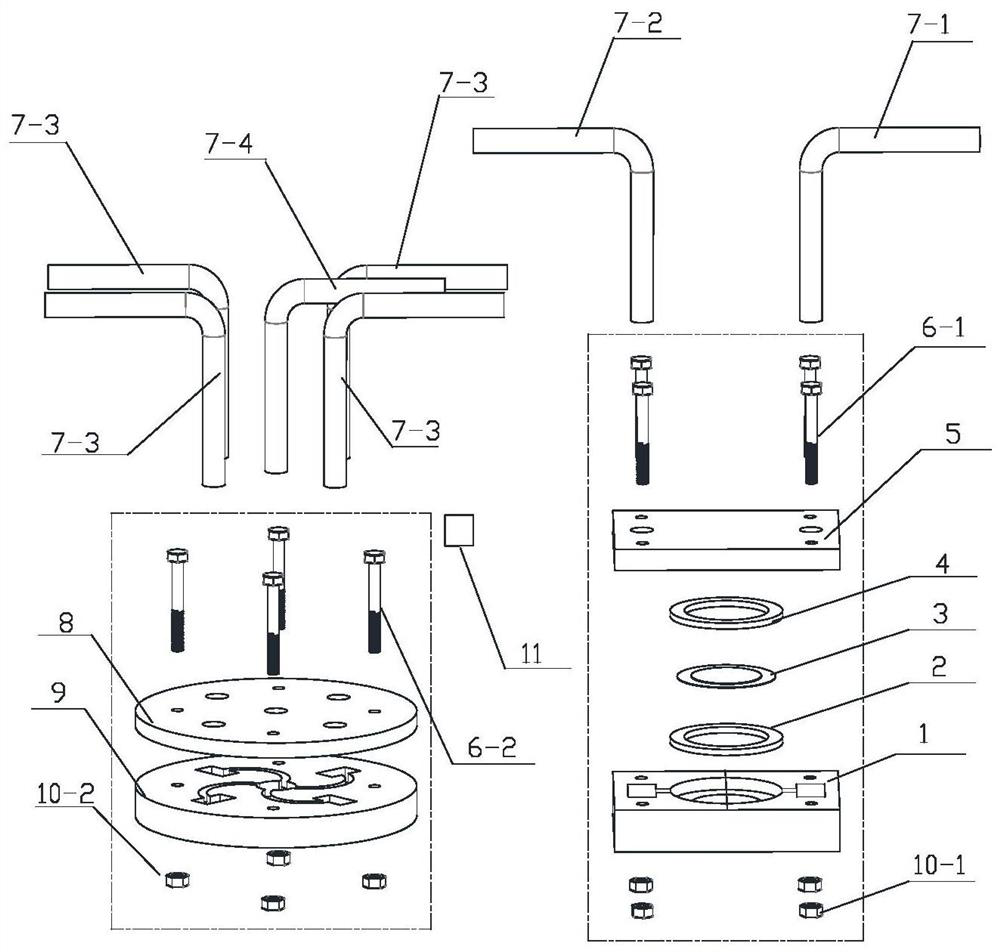

[0038] Such as Figure 1 to Figure 4 As shown, a valveless piezoelectric pump with separated drive and flow resistance structure, including drive structure, water inlet pipe I7-1, water outlet pipe I7-2, flow resistance structure, water inlet pipe II7-4 and multiple outlet pipes II7- 3;

[0039] The driving structure includes the pump base I1, the piezoelectric vibrator 3 and the pump cover I5, such as Figure 5 As shown, the middle of the pump base I1 is provided with a liquid chamber 1-5 and a pump chamber 1-4 from bottom to top, the piezoelectric vibrator 3 is placed in the pump chamber 1-4, and the piezoelectric vibrator 3 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com