Cylindrical heater

A cylindrical heater and a cylindrical technology, applied in the direction of heating elements, heating element shapes, ohmic resistance heating, etc., can solve the problems of more manufacturing processes and low heating efficiency, and achieve the effect of easy installation and operation and high heating efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

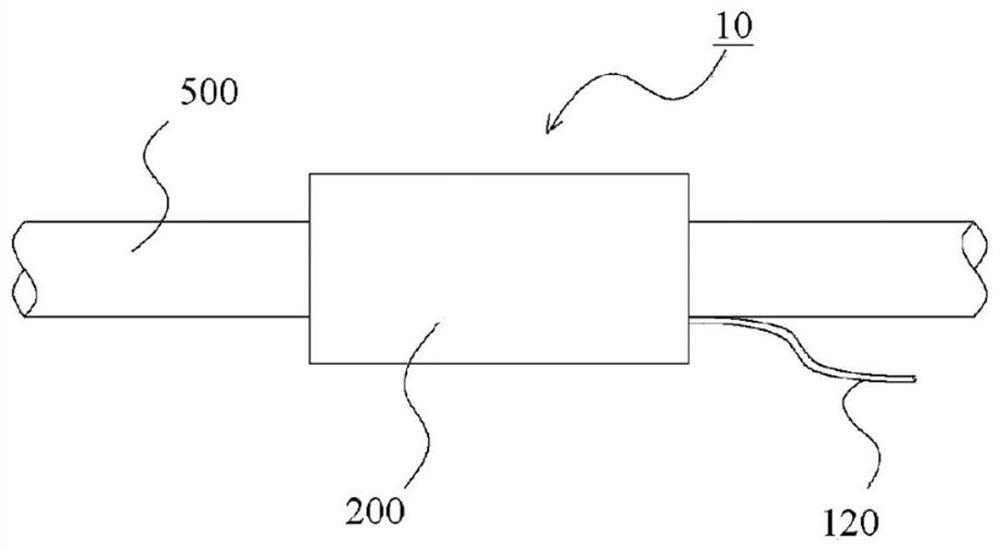

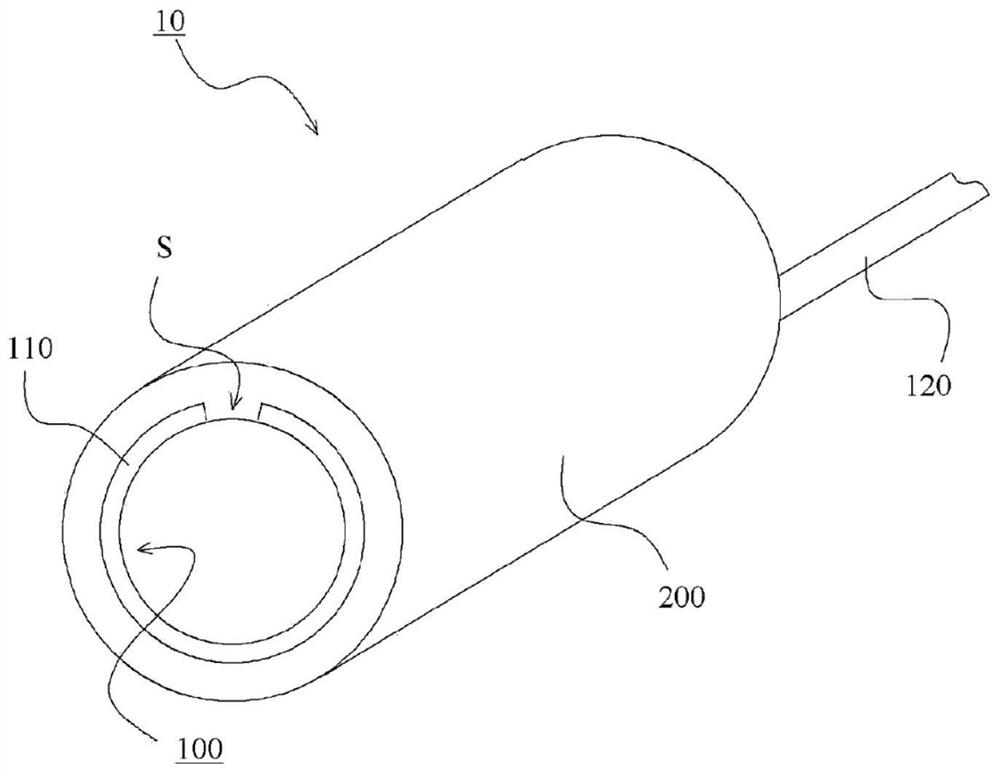

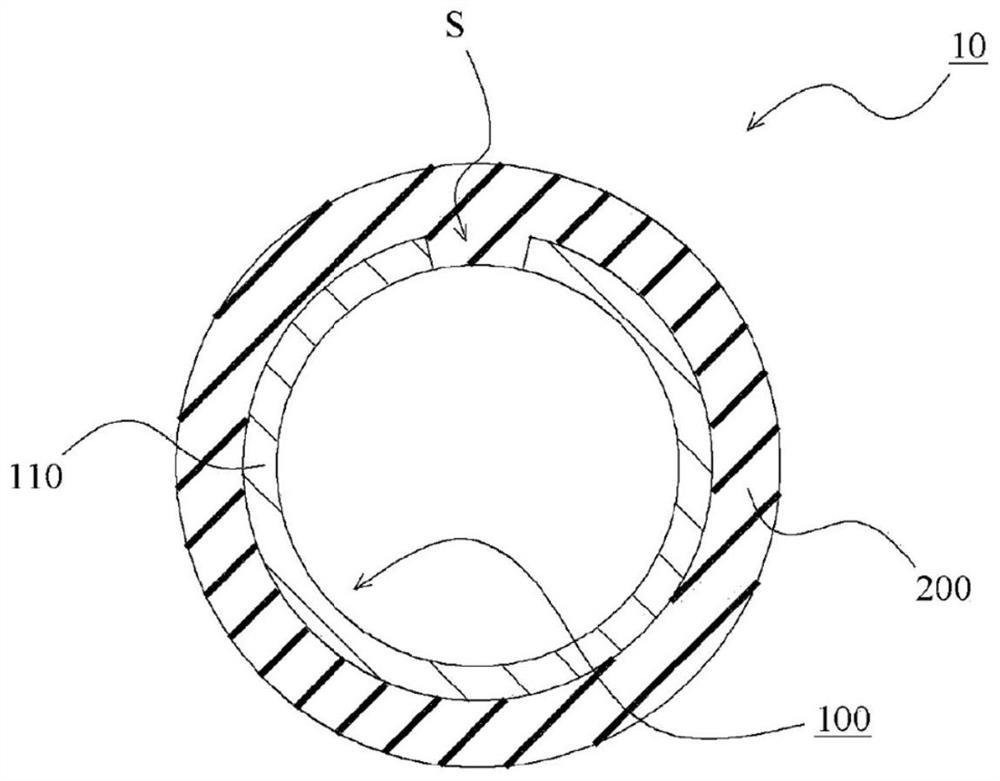

[0027] refer to Figure 1 to Figure 5 , the cartridge heater according to the embodiment of the present invention will be described. figure 1 It is an external view showing an example of use of the cartridge heater in the embodiment of the present invention, and shows the vicinity of the cartridge heater attached to the heating object. figure 2 is a perspective view of a cartridge heater in an embodiment of the present invention. image 3 is a schematic sectional view of a cartridge heater in an embodiment of the present invention. In addition, the cartridge heater in this embodiment is cylindrical, image 3 , shows a cross-sectional view of the cartridge heater taken along a plane perpendicular to the central axis of the cylinder. Figure 4 and Figure 5 It is a manufacturing process diagram of the cartridge heater in the Example of this invention.

[0028] (Examples of use of cartridge heaters)

[0029] like figure 1 As shown, the cartridge heater 10 in this embodi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com