Centrifugal gas dehumidification device

A centrifugal, gas technology, used in gas treatment, separation methods, dispersed particle separation, etc., can solve the problems of high energy consumption and low air dehumidification efficiency, and achieve low energy consumption, easy miniaturization and huge manufacturing needs , Efficient dehumidification effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

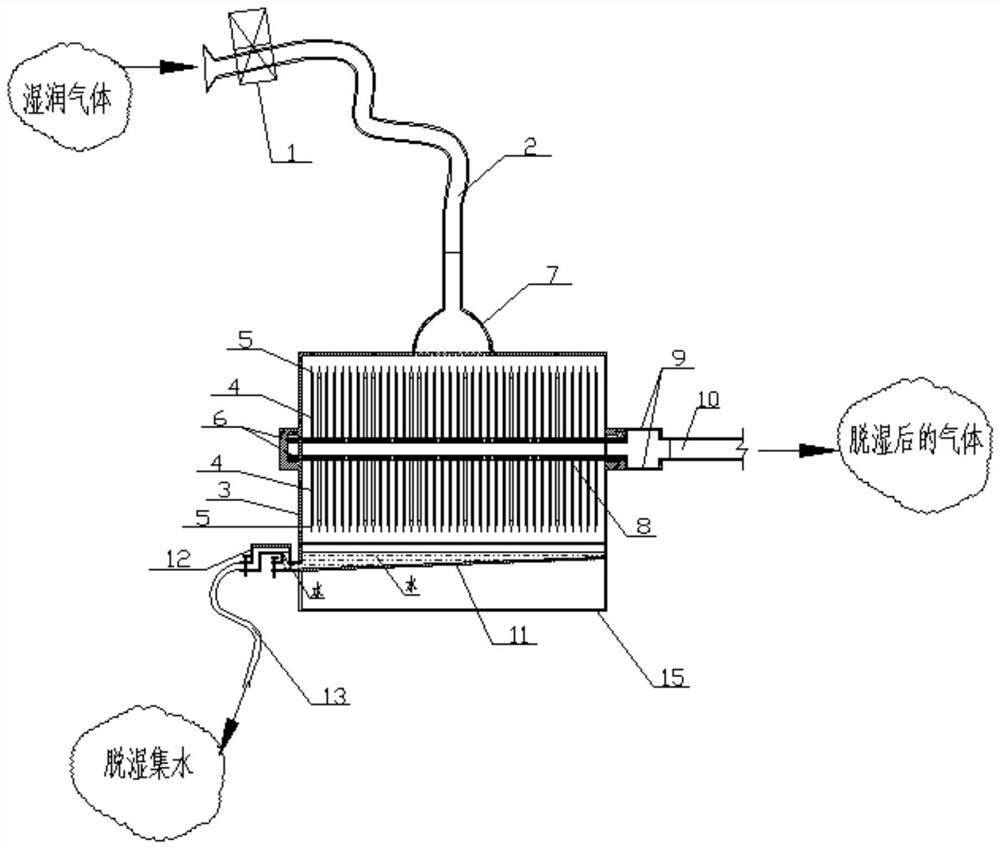

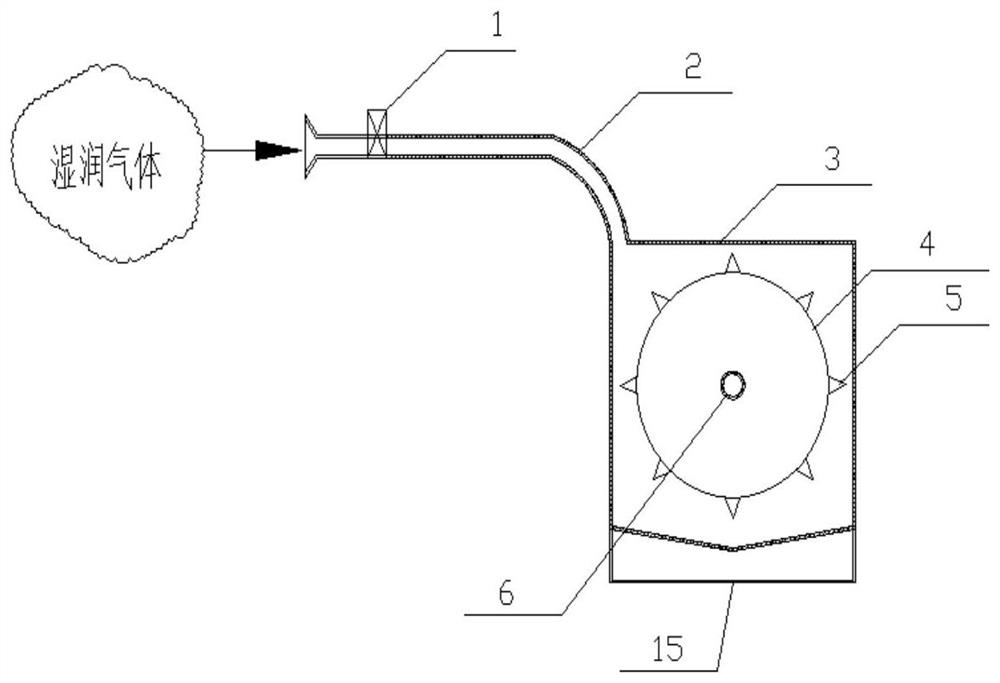

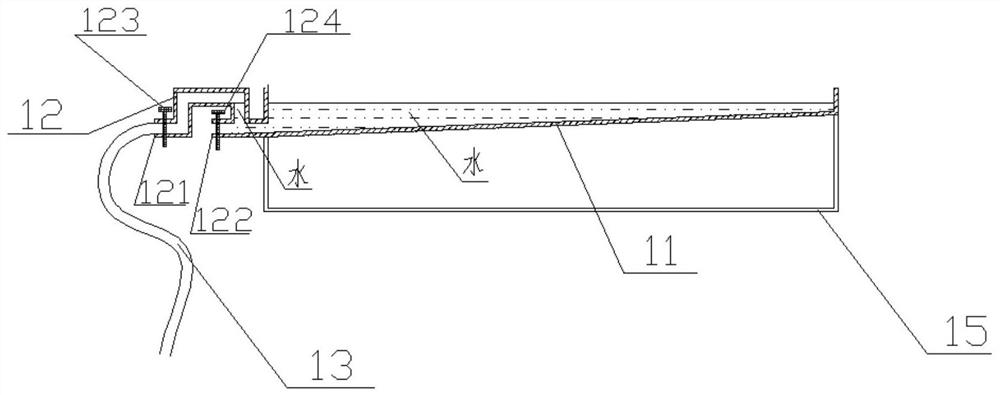

[0029] Embodiment 1: as Figure 1-4 As shown, a centrifugal gas dehumidification device includes an air pump 1, an air guide tube 2, a sealed box 3, a light hard disc 4, a water collecting tip 5, a hollow rotating shaft 6, an expanded air inlet 7, a communication hole 8, Air outlet 9, air outlet conduit 10, sink 11, water outlet 12, water guide pipe 13;

[0030] The air pump 1 is used to pump the gas to be dehumidified in the environment into the dehumidification device. The air pump 1 is connected to the inlet end of the air guide tube 2, and the outlet end of the air guide tube 2 is connected to the expansion air inlet 7, and the expansion air inlet 7 It is connected with the middle part of the top of the sealing box 3, and the inner cavity of the sealing box 3 is provided with a hollow rotating shaft 6 horizontally. Disc 4, the top of each said lightweight hard disc 4 is provided with some water collecting tips 5, and several communication holes 8 are arranged between two ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com