Method for treating workpiece through water jet

A technology of water jet and workpiece, applied in the direction of jetting device, etc., can solve the problems of small processing surface, poor processing uniformity and low work efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

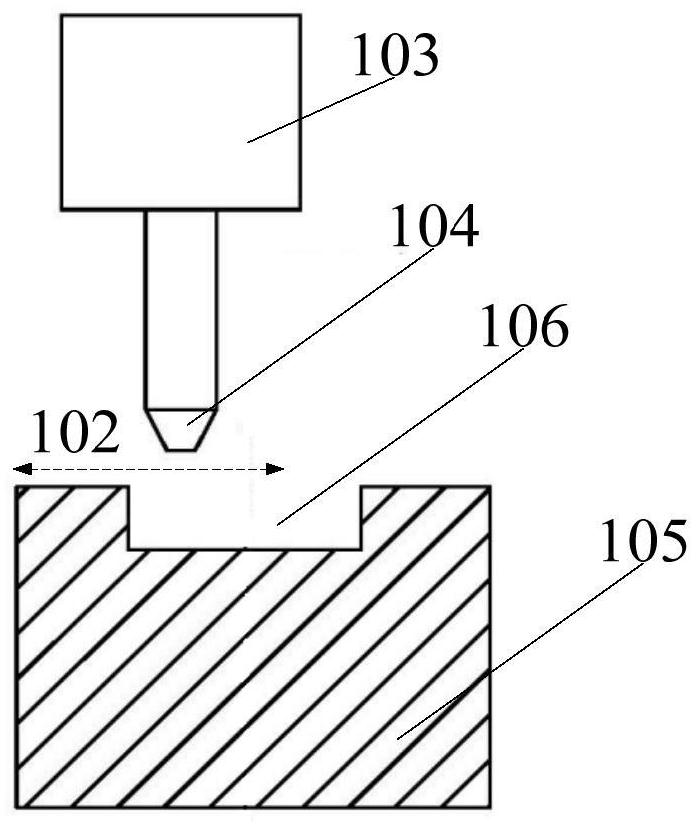

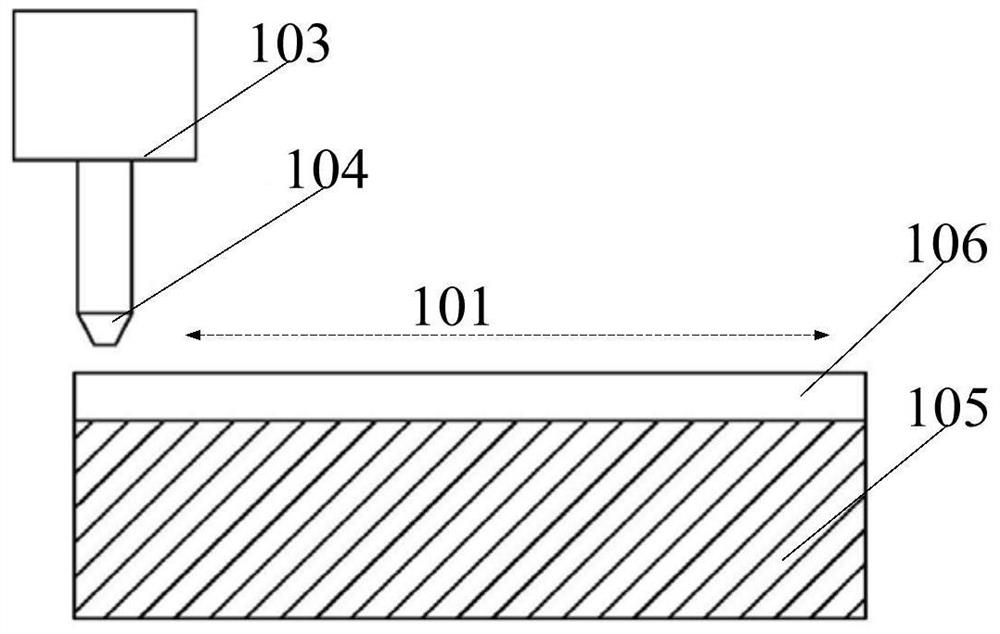

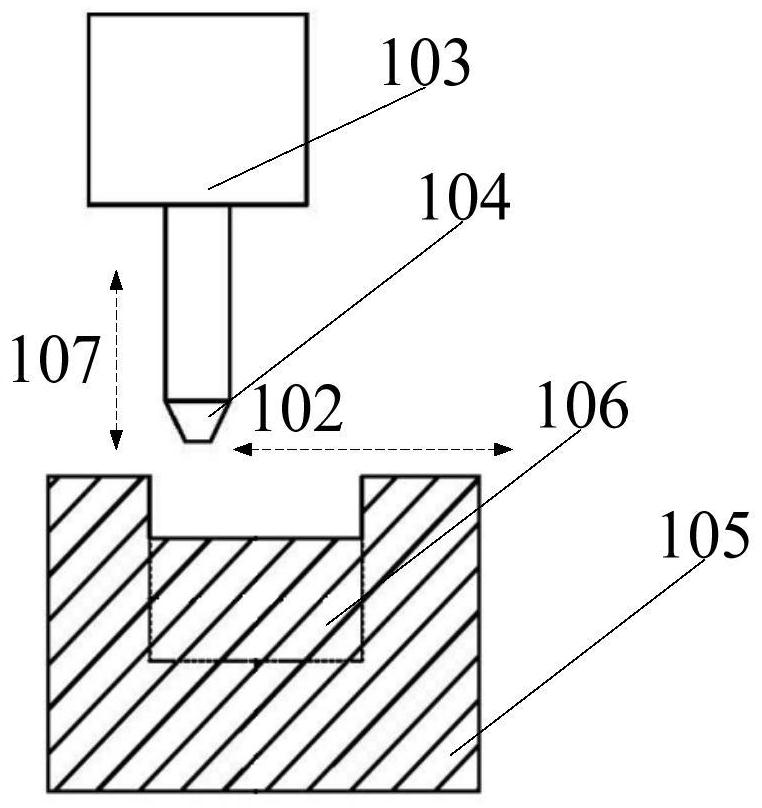

[0053] Taking the cleaning of the surface of the workpiece 105 to be processed as an example for illustration, it is first necessary to measure the size of the pretreatment area 106 on the surface of the workpiece 105 to be processed; specifically, measure the length of the pretreatment area 106 as L, measure The width of the pre-treatment area 106 is denoted as H and the thickness of the pre-treatment area 106 is measured as W. Then, the diameter of the nozzle 104 of the spray gun 103 was set to 1.2 mm.

[0054] combine figure 1 and figure 2 As shown, if it is judged that the thickness W of the pretreatment area 106 is zero, and the width H of the pretreatment area 106 is less than the diameter of the nozzle 104 of the spray gun 103, then a group of spray gun groups 100 can be used, and the spray gun group 100 has a Spray gun 103, has a nozzle 104 on the spray gun 103 to carry out water jet treatment to be processed workpiece, concrete processing method is as follows:

[...

Embodiment 2

[0062] The method for treating workpieces with water jets in this second embodiment is an improvement on the basis of the above-mentioned embodiments. The technical content disclosed in the above-mentioned embodiments will not be described repeatedly, and the content disclosed in the above-mentioned embodiments also belongs to the content disclosed in this second embodiment. .

[0063] In this embodiment, the measurement of the pretreatment area 106 and the setting of the diameter of the nozzle 104 of the spray gun 103 are based on the first embodiment.

[0064] In order to further improve the cleaning efficiency of the water jet, in this embodiment, a group of spray gun groups 100 are adopted, the spray gun group 100 has a spray gun 103, and the spray gun 103 has two nozzles 104 for water jet treatment of workpieces to be processed, specific processing Methods as below:

[0065] to combine Figure 6 As shown, drive the spray gun group 100 to move linearly along the first di...

Embodiment 3

[0067] The method for treating workpieces with water jets in the third embodiment is an improvement on the basis of the above-mentioned embodiments. The technical content disclosed in the above-mentioned embodiments will not be described repeatedly, and the content disclosed in the above-mentioned embodiments also belongs to the content disclosed in the third embodiment. .

[0068] In this embodiment, the measurement of the pretreatment area 106 and the setting of the diameter of the nozzle 104 of the spray gun 103 are based on the first embodiment.

[0069] On the basis of embodiment two, in order to further improve the cleaning work efficiency of water jet, in this embodiment, adopt a group of spray gun group 100, have a spray gun 103 on the spray gun group 100, have three nozzles 104 on the spray gun 103 to carry out water Jet treatment of workpieces to be processed, the specific processing methods are as follows:

[0070] to combine Figure 7 As shown, drive the spray gu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com