Intelligent forging equipment and forging method thereof

A kind of equipment and intelligent technology, which is applied in the direction of metal processing equipment, manufacturing tools, forging/pressing/hammer devices, etc., can solve the problems of reducing the labor intensity of the staff, time-consuming and labor-intensive forging parts, and unfavorable problems, so as to reduce labor costs and achieve good results. Application prospects and the effect of improving work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

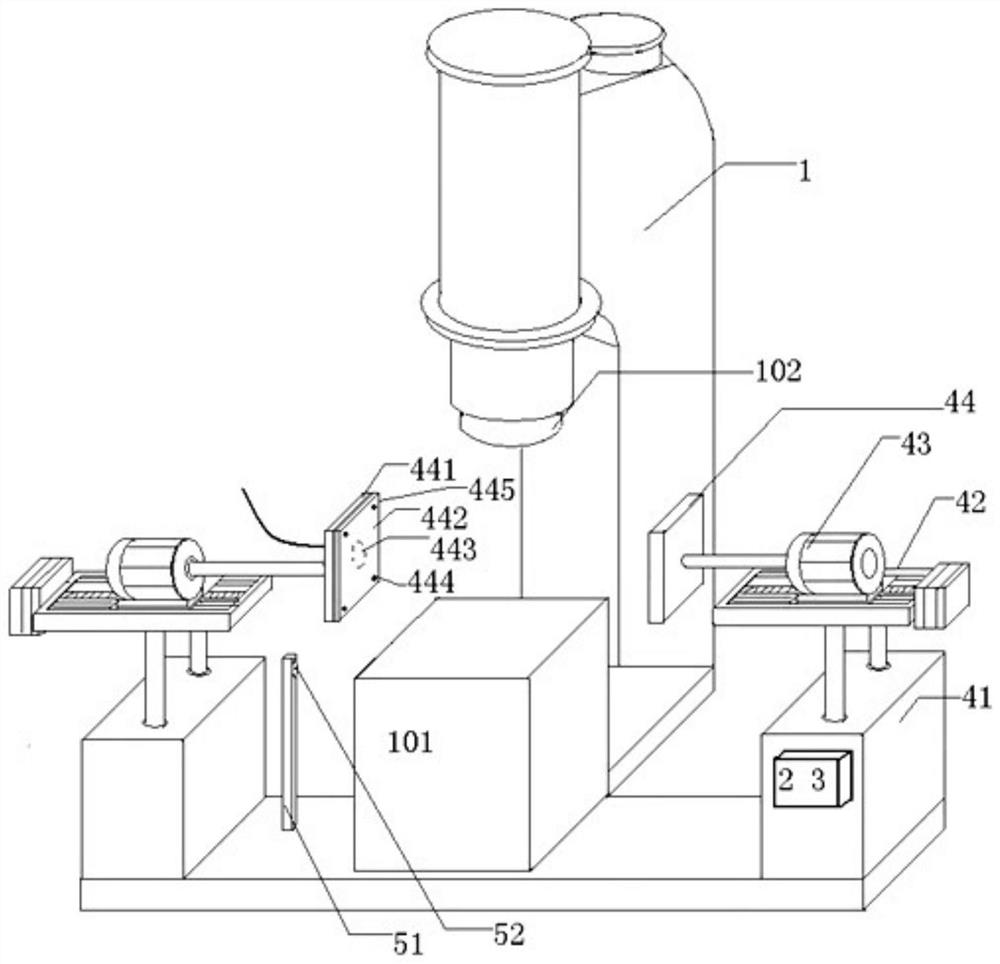

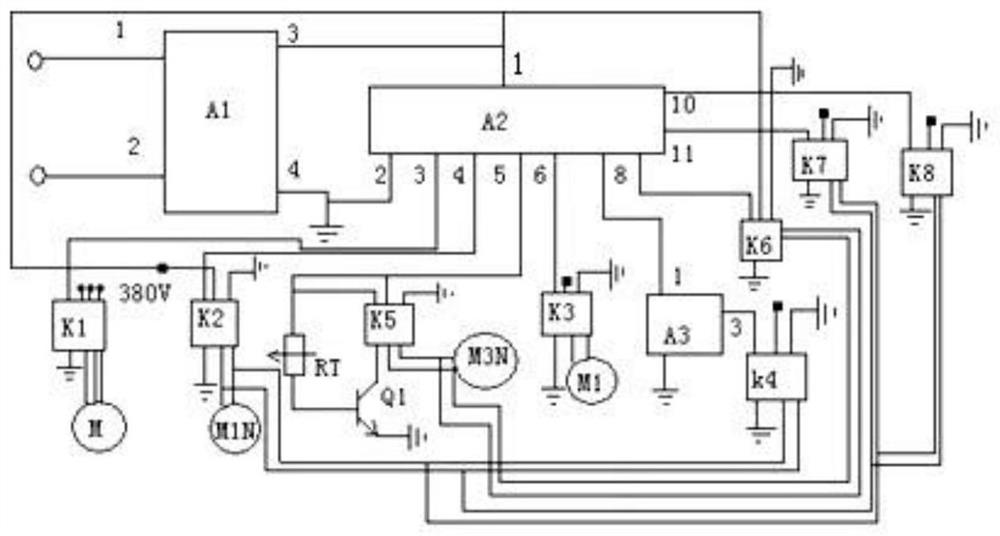

[0019] figure 1 , 2 As shown, an intelligent forging equipment includes a forging equipment body 1 using an air hammer as the forging power, a stabilized power supply 2; it also has a height detection mechanism, an overturning mechanism and a control circuit 3; there are two sets of the overturning mechanism, Each set of overturning mechanisms includes an electric push rod type lifting platform 41, an electric screw rod linear slide 42, a motor reduction mechanism 43 and a top plate 44; The screw nuts are installed on the upper ends of the two piston rods of the electric push rod lifting platform 41, the motor reduction mechanism 43 is installed horizontally on the upper end of the sliding block of the electric screw linear slide table 42 through the screw nuts, and the middle part of one side of the top plate 44 is installed through the screw nuts Before the power output shaft of the motor reduction mechanism 43; the lower ends of the housings of the electric push rod type l...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com