Bevel gear clamping fixture

A technology of helical gears and gears, which is applied in the field of helical gear clamping fixtures, can solve problems such as the difficulty of clamping gears, and achieve the effect of rapid positioning and cutting

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

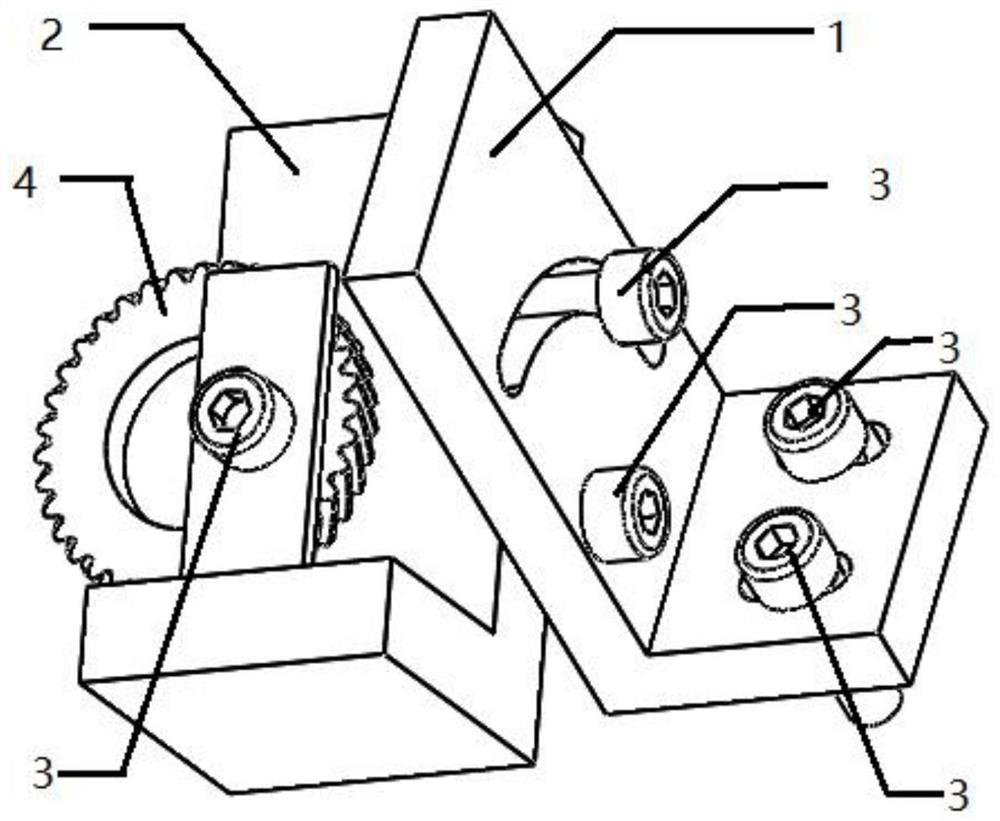

Image

Examples

Embodiment 1

[0023] according to the above figure 1 As shown, a helical gear clamping fixture device is prepared, wherein the L-shaped iron 1 is installed on the wire cutting workbench to ensure verticality, the thickness is 12mm, the height is 100mm, and the base width is 50mm; the diameter of the through hole is 11mm, the center of the circle is 10mm from the side, and the distance The bottom edge is 32mm; the width of the fan-shaped groove on the main plane is 11mm, the center of the fixed through hole is the center, the radius is 20mm, and the arc length is 31mm, which is about 1 / 4 circle; the bottom surface of the L-shaped iron 1 is provided with two through holes with a diameter of 11mm, which are used for bolts The nut is connected with the wire cutting workbench; the L-shaped iron 2 is tightly connected with the L-shaped iron 1, with a thickness of 16mm, a height of 98mm, and a width of the bottom surface of 40mm. There is a through hole for the fixed connection of the helical gear....

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| height | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com