Machining method of E-shaped bushing

A processing method and bushing technology, which is applied in the field of E-type bushing processing, can solve problems such as deviation, high eccentricity of plastic lenses, and inability to use the same set of processing and positioning fixtures, so as to avoid eccentricity and improve product quality.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0037] The technical scheme of the present invention is further described below by the examples:

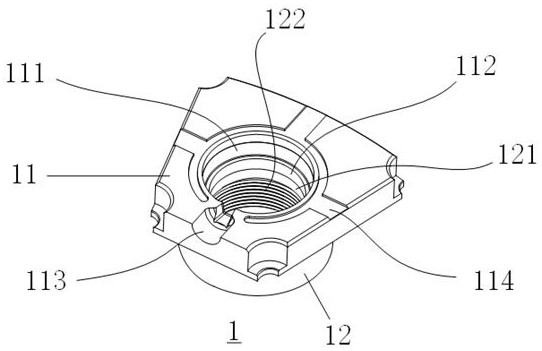

[0038] The present invention provides an E-type bushing, such as figure 1 As shown, the E-type bushing 1 has a special-shaped plate 11 and a positioning cylinder 12, the special-shaped plate 11 is fixed on the upper end of the positioning cylinder 12, the inside of the special-shaped plate 11 has a cavity 111 and a positioning channel 112, and the upper surface of the special-shaped plate 11 has glue The port 113 and the flow channel 114, the positioning cylinder 12 is cylindrical, the interior of the positioning cylinder 12 has a truncated channel 121 and an inner thread 122, and the truncated channel 121 is located on the upper side of the inner thread 122.

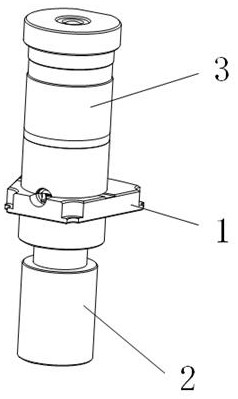

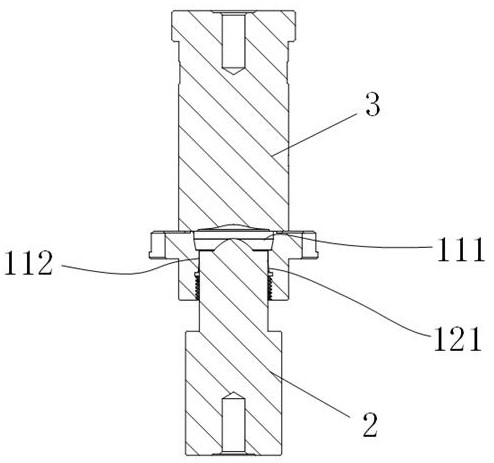

[0039] combine figure 2 and image 3 As shown, during the use of the E-type bushing 1, the internal thread 122 engages with the bolts in the mold, thereby fixing the E-type bushing 1, and the upper end of the lower mold...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com