A celery stick auxiliary cutting machine

A technology of cutting machine and lifting rod, which is applied in metal processing and other directions, can solve the problems of time-consuming and labor-intensive, inaccurate control of mouth opening, etc., and achieve the effect of reducing manual operation, facilitating cutting and fast collection

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

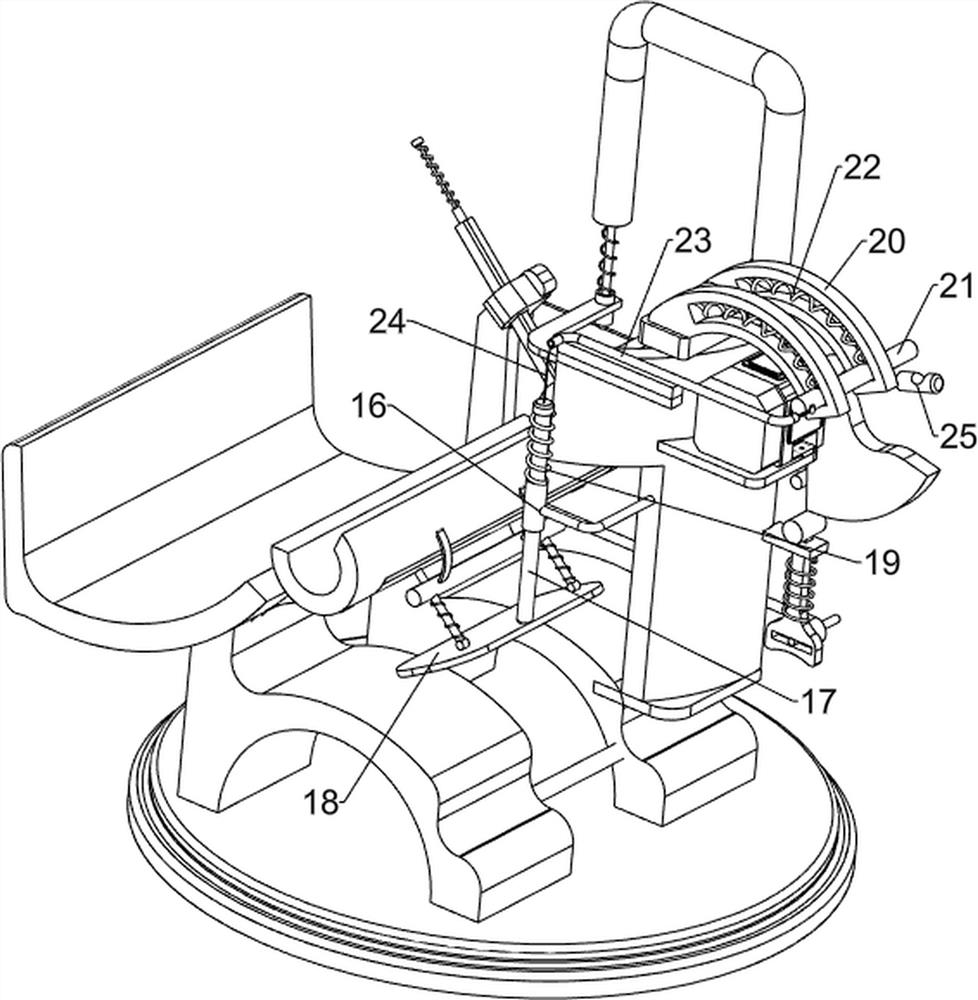

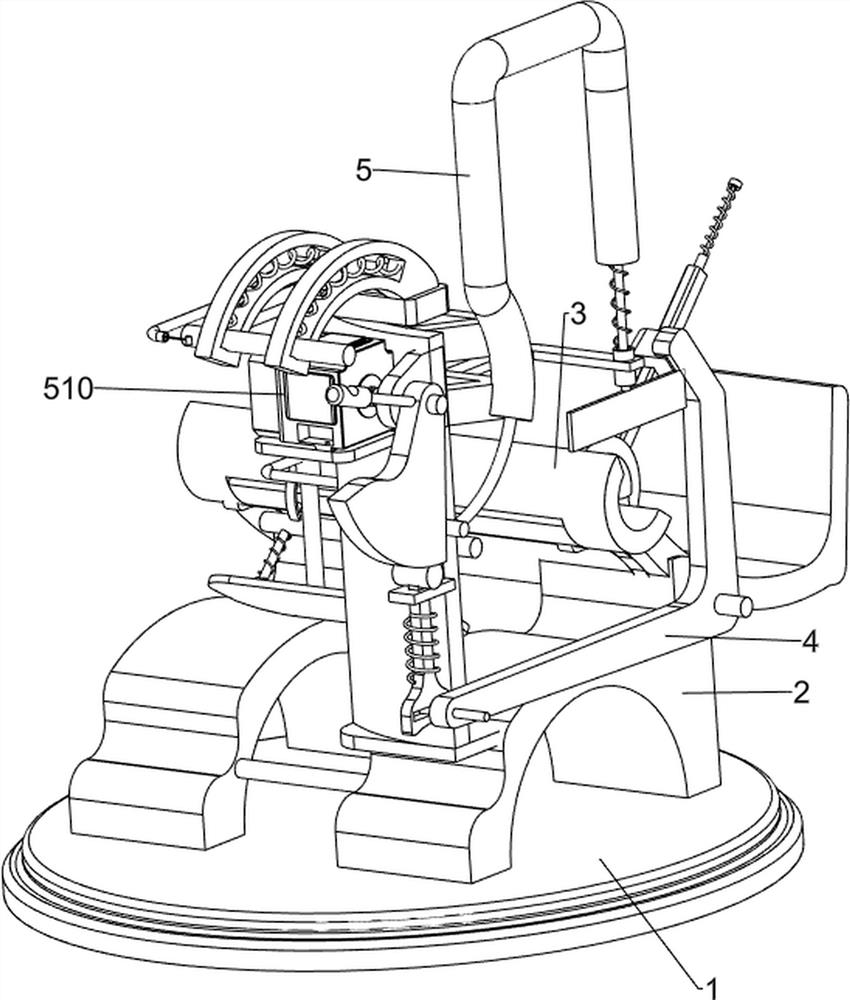

[0026] like figure 1 , figure 2 and image 3 As shown, a celery rod auxiliary cutting machine includes a base 1, a worktable 2, a placing table 3, a pressing mechanism 4 and a cutting mechanism 5. The top of the base 1 is symmetrically provided with a worktable 2, and the top of the worktable 2 is provided with There is a placing table 3 , a pressing mechanism 4 is arranged on the right side wall of the right working table 2 , and a cutting mechanism 5 is arranged on the front side wall of the right working table 2 .

[0027] The pressing mechanism 4 includes a fixed shaft 401, a folding frame 402, a mounting block 403, a fixed rod 404 and a pressing block 405. A fixed shaft 401 is provided on the right side wall of the right table 2, and the fixed shaft 401 is rotatably arranged There is a folding frame 402 , a mounting block 403 is provided on the upper end side wall of the folding frame 402 , a fixing rod 404 is fixed on the mounting block 403 , and a pressing block 405 ...

Embodiment 2

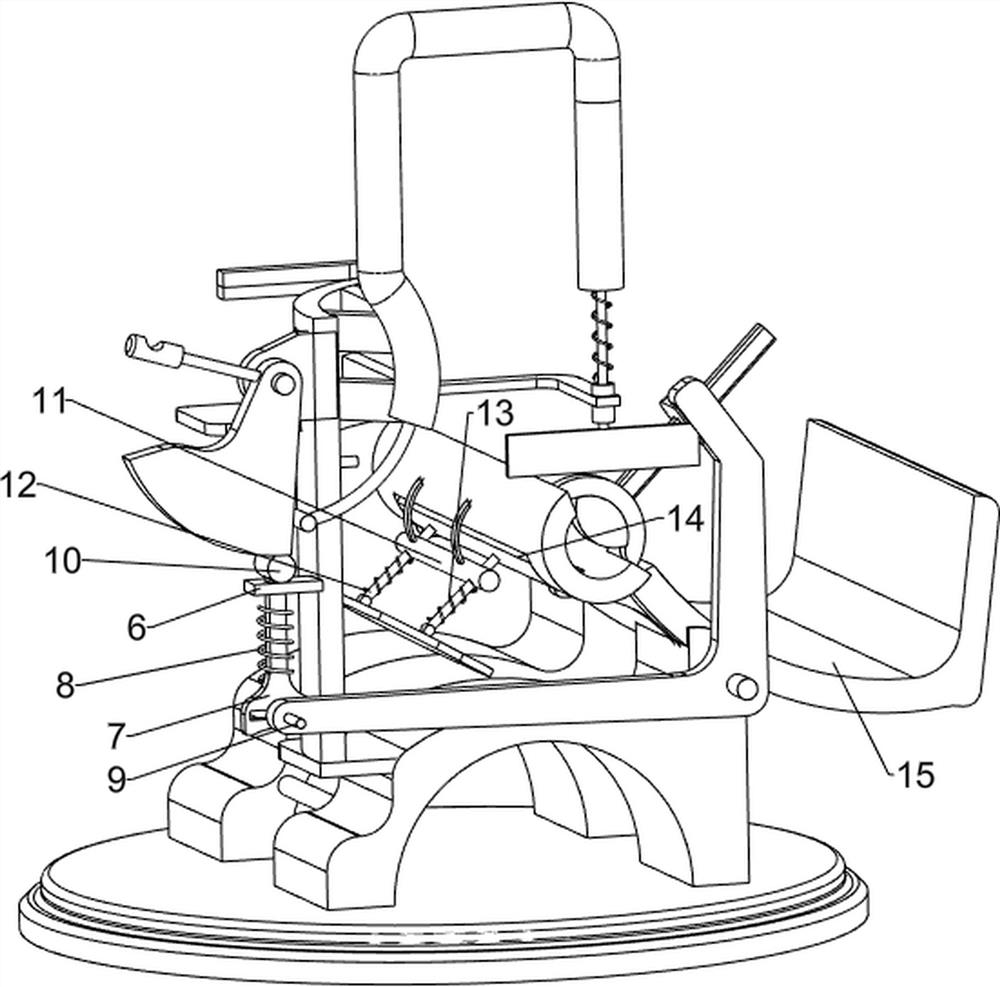

[0031] like Figure 4 , Figure 5 and Image 6As shown, on the basis of Embodiment 1, it also includes a guide block 6, a guide rod 7, a second elastic member 8, a first sliding shaft 9 and a top column 10. The lower part of the fixing frame 501 is provided with a guide block 6, which guides the A guide rod 7 is slidably arranged in the block 6, a character slot is formed at the bottom of the guide rod 7, a second elastic member 8 is connected between the guide rod 7 and the guide block 6, and the front end of the folding frame 402 is provided with a first sliding shaft 9 , the first sliding shaft 9 is slidingly matched with the slot of the guide rod 7, the top of the guide rod 7 is provided with a top column 10, the top column 10 is matched with the arc surface of the special-shaped top block 509, and the special-shaped top block 509 rotates counterclockwise. Push the top post 10 down.

[0032] The staff controls the servo motor 510 to drive the special-shaped top block 50...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com