A turntable mechanism with pre-screening function in a bottle unscrambler

A technology of turntable mechanism and bottle unscrambler, applied in the field of bottle unscrambler, can solve problems such as increased cost, high screening pressure, cumbersome operation, etc., and achieve the effect of reducing screening pressure and ensuring stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

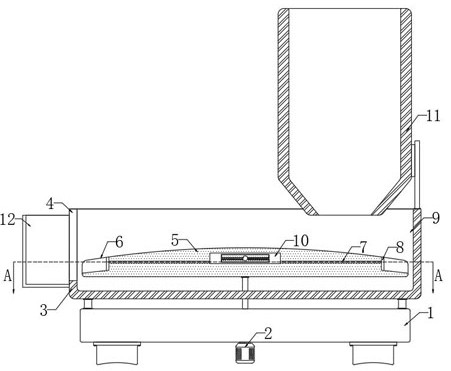

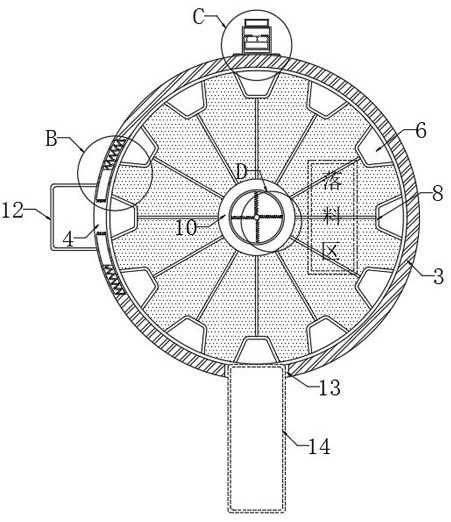

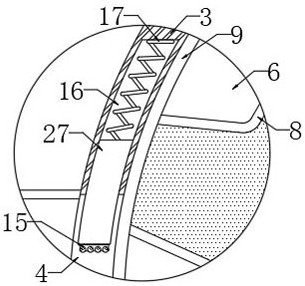

[0033] refer to Figure 1-5 , a turntable mechanism with a pre-screening effect in a bottle unscrambler, including a support base 1, a plurality of connecting columns are installed on the upper end of the supporting base 1, and a housing 3 is fixedly connected to the upper ends of the plurality of connecting columns. The housing 3 The upper end of the upper end is provided with a processing tank 9, the processing tank 9 is provided with a rotating plate 5, the upper end of the rotating plate 5 is provided with a plurality of finishing grooves 6, the rotating plate 5 is provided with a columnar cavity 10, and the lower end of the support seat 1 is equipped with multiple The base, the upper end of the housing 3 is provided with a feeding hopper 11, and the upper end surface of the rotating plate 5 is a circular arc surface, which ensures that the bottles falling from the feeding hopper 11 on the rotating plate 5 can slide into the corresponding finishing groove 6, and more The i...

Embodiment 2

[0046] refer to Figure 6-7 The difference between this embodiment and Embodiment 1 is that the upper end of the rotating plate 5 is fixedly connected with the installation rod 24, and the upper end of the installation rod 24 is fixedly connected with the rotating disk 25, and the rotating disk 25 is uniformly provided with a plurality of blanking Port 26, a plurality of blanking ports 26 are all matched with the discharge end of the feed hopper 11.

[0047] In this embodiment, when in use, the rotation of the rotating plate 5 will drive the rotating disk 25 to rotate, so that the multiple blanking ports 26 on the rotating disk 25 can be connected to the blanking end of the feeding hopper 11 intermittently, realizing Intermittent blanking, at this time, the user does not need to put the bottles that need to be sorted into the feed hopper 11 for a small number of times, and can put more bottles at one time. The intermittent blanking can make the bottles that fall into the blank...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com