Plate turnover machine for machining

A technology of mechanical processing and turning machine, which is applied in the direction of conveyors, conveyor objects, transportation and packaging, etc. It can solve the problems of noise caused by turning over, failure to fix the plate, and damage to the plate, so as to avoid shaking, improve the versatility of the device, The effect of increasing stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

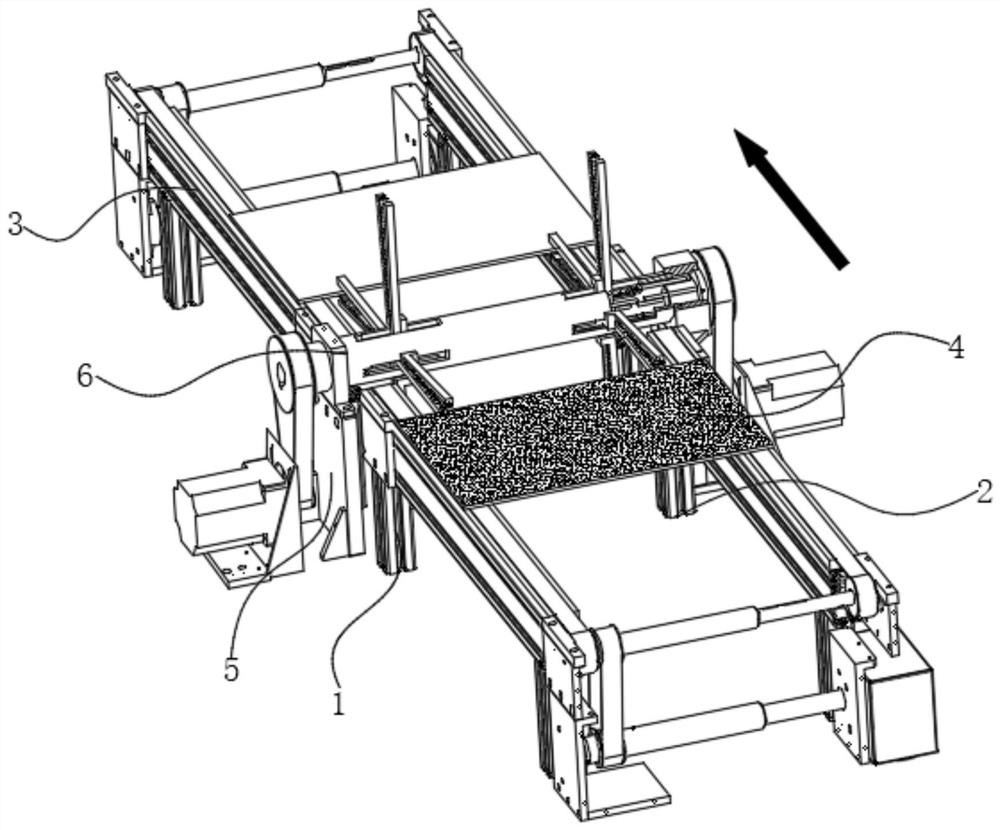

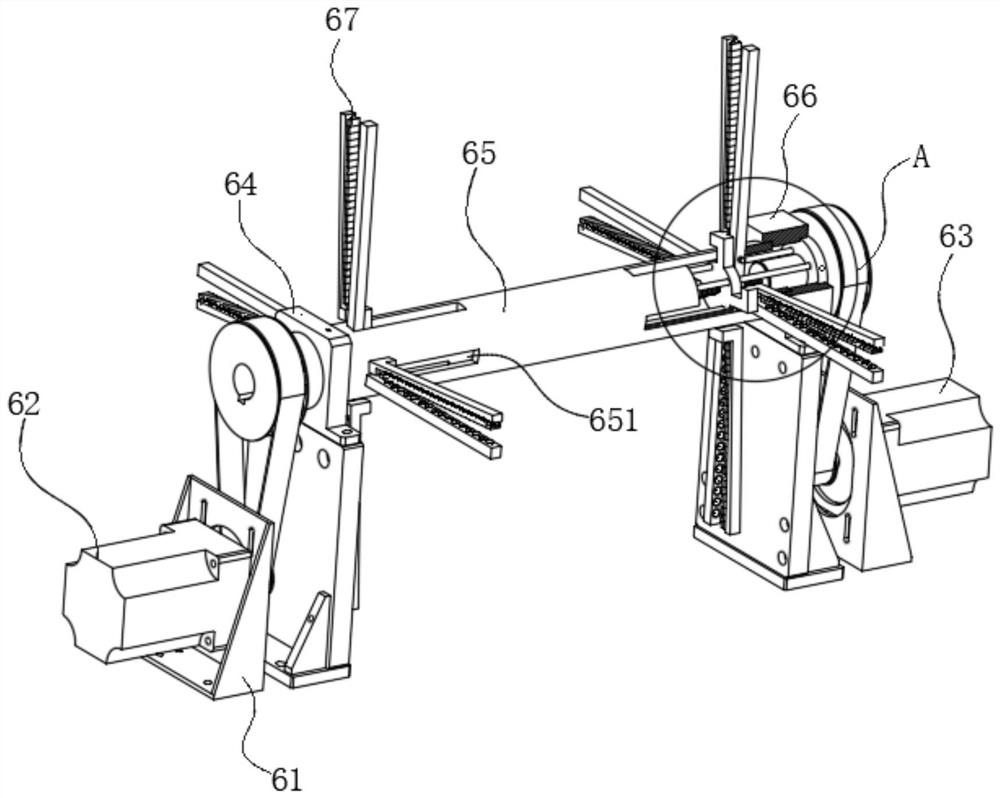

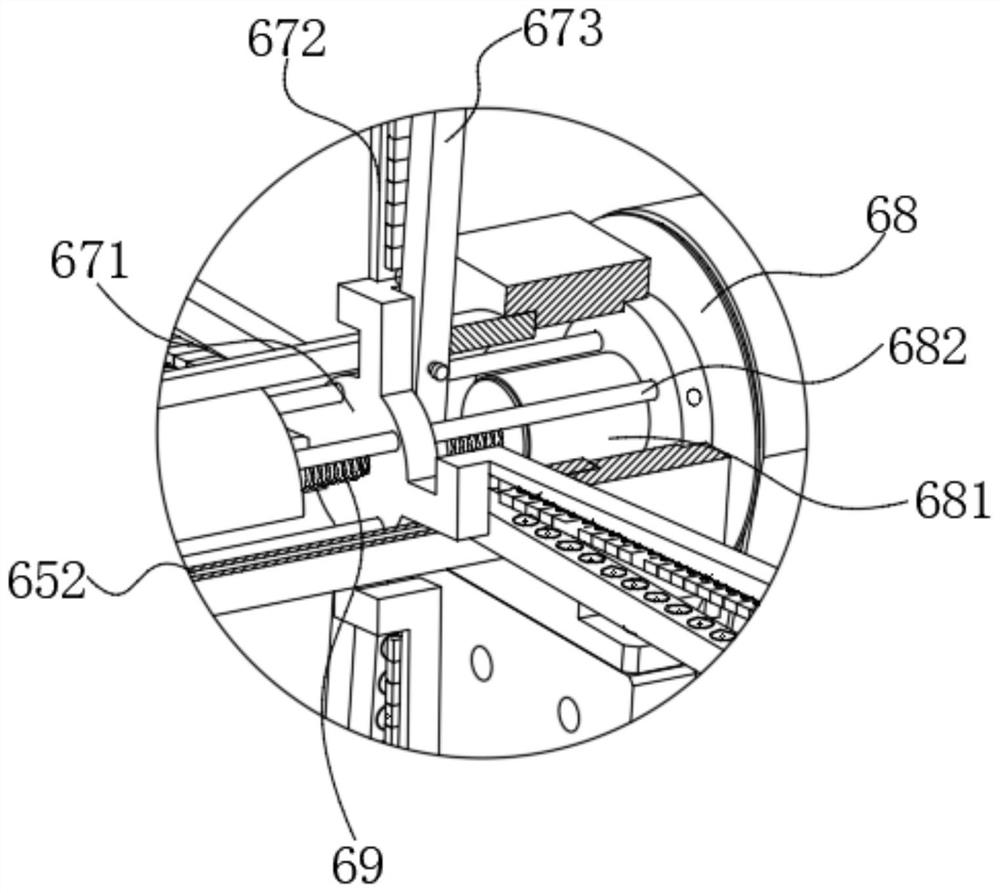

[0029] refer to Figure 1~2 , the present invention provides a technical solution: a plate turning machine for mechanical processing, including a support frame 1, a conveyor belt 3, a support plate 5 and a turning assembly 6, wherein the lower end surface of the conveyor belt 3 is symmetrically arranged with A plurality of support frames 1, the bottoms of the plurality of support frames 1 are provided with adjustable foot cups 2 for adjusting the height of the conveyor belt 3, it should be noted that the height of the conveyor belt 3 needs to be slightly higher than the height of the turning assembly 6 , so that the plate 4 enters into the turning assembly 6;

[0030] The conveyor belt 3 can continuously transport the plates 4, and the overturning assembly 6 adopts two support plates 5 to be erected on both sides of the conveyor belt 3, and the conveyor belt 3 is a double-track conveyor belt with a hollow middle, which is convenient for the overturning assembly 6 to pair the p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com