A kind of municipal curb stone construction equipment and using method thereof

A construction equipment and curb stone technology, which is applied in the field of municipal curb stone construction equipment, can solve the problems of large weather impact, reduced curb stone quality, and impact on the appearance of laying.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0039] The following are specific embodiments of the present invention and the accompanying drawings to further describe the technical solutions of the present invention, but the present invention is not limited to these embodiments.

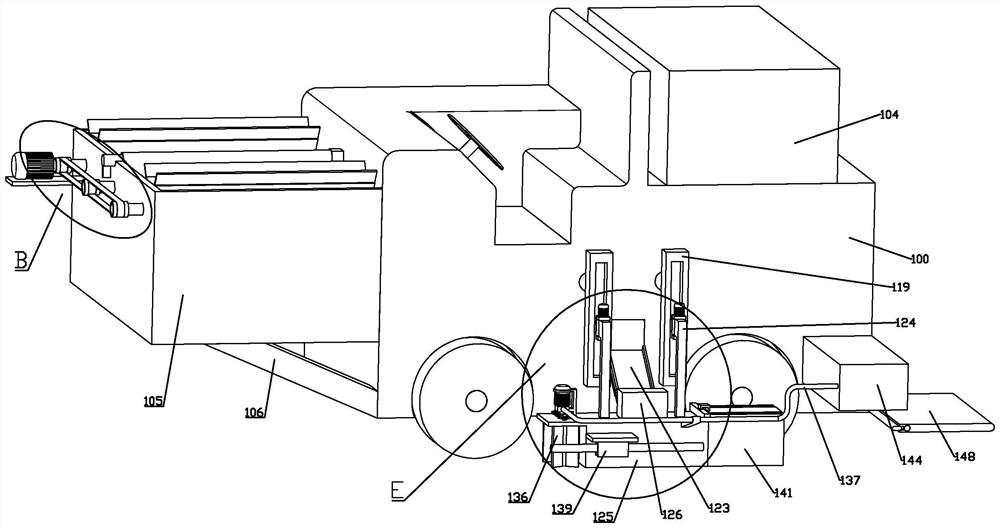

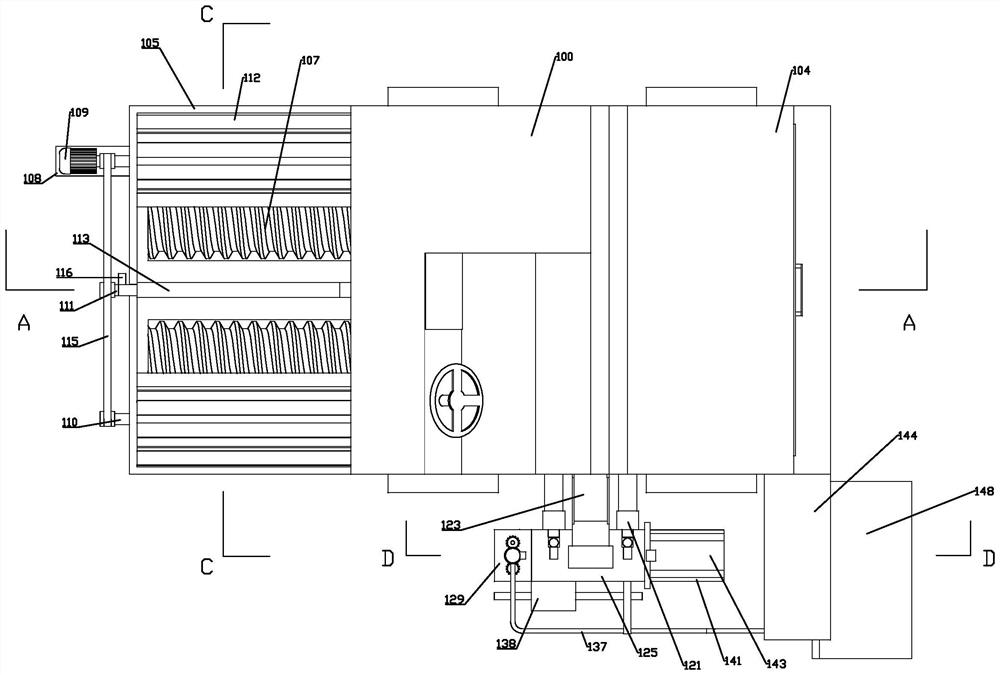

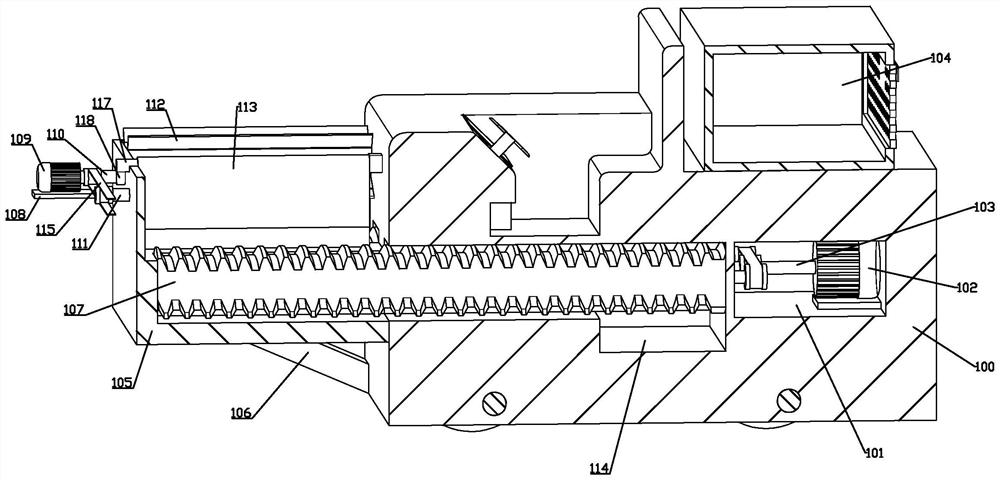

[0040] like figure 1 , figure 2 and image 3 As shown, a municipal curb stone construction equipment includes a working car 100, a motor cavity 101 is defined in the working car 100, a feeding cavity 114 is defined on the left side of the motor cavity 101 in the working car 100, and the upper end surface of the working car 100 is provided with The electric control box 104, the left end face of the working car 100 is provided with a feeding hopper 105, two support rods 106 are arranged between the lower end of the feeding hopper 105 and the left end of the working car 100, and a shaping mechanism, a plastic mechanism, which is communicated with the feeding mechanism is provided. The left end is provided with an impurity removal mechanism, the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com