A prefabricated building cold-formed thin-walled light steel skeleton transfer device

A technology of cold-formed thin-walled and transfer devices, which is applied in construction, building construction, tool storage devices, etc., and can solve problems such as prolonged construction time, inconvenient transportation of skeletons, and multiple site areas

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

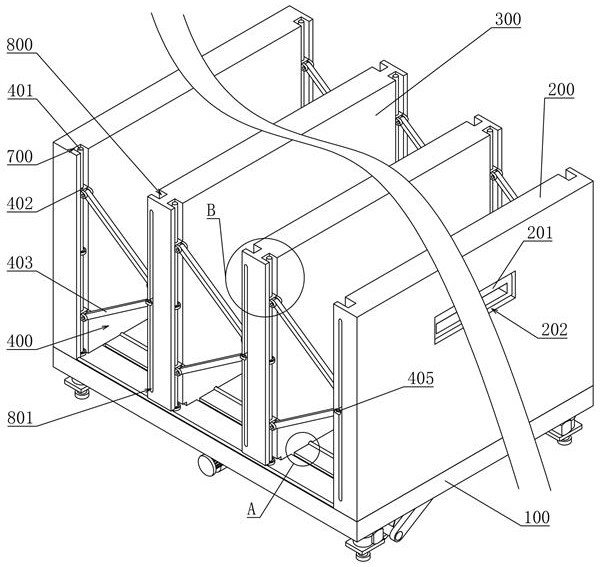

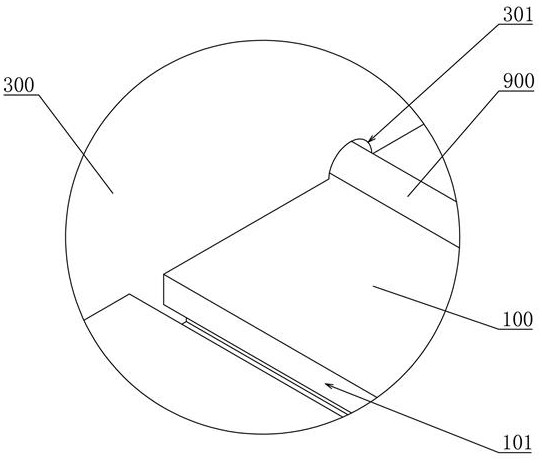

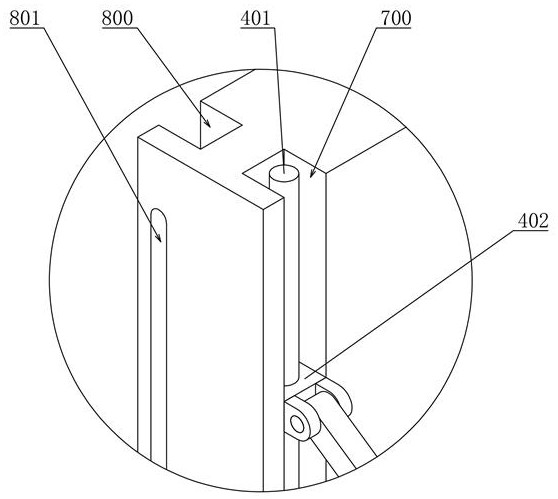

[0025] Such as Figure 1-8 As shown, it is a prefabricated building cold-formed thin-walled light steel framework transfer device disclosed by the present invention, which includes a base plate 100, and the upper end of the base plate 100 is fixedly connected with two side plates 200 arranged in parallel, and the side plates 200 are located in the length direction of the base plate 100 On both sides of the bottom plate 100, there are sliding grooves 101 on the upper end surface of the bottom plate 100. The sliding grooves 101 are located at both ends of the bottom plate 100 in the length direction. The plate 300, the isolation plate 300 is placed parallel to the side plate 200, the blocking assembly 400 is arranged between the side plate 200 and the adjacent isolation plate 300, and between two adjacent isolation plates 300, and the lower end surface of the bottom plate 100 is provided with a moving assembly 500 There are two sets of supporting components 600 and moving compon...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com