Leak detection device for pump body and leak detection equipment

A pump body and leak detection technology, which is used in mechanical equipment, pump testing, liquid variable capacity machinery, etc. Good, convenient and fast detection, the effect of saving water resources

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

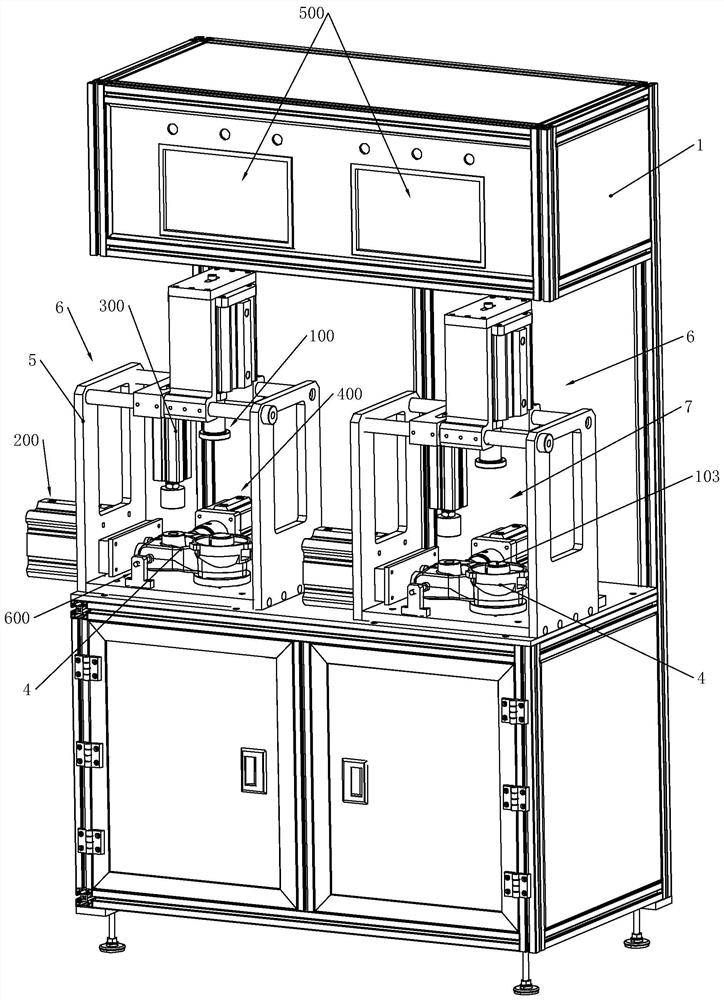

[0085] Such as figure 1 As shown, a leak detection device includes a body 1 on which two sets of pump body leak detection devices are installed, which can work simultaneously to perform leak detection operations on two pump bodies 4 . .

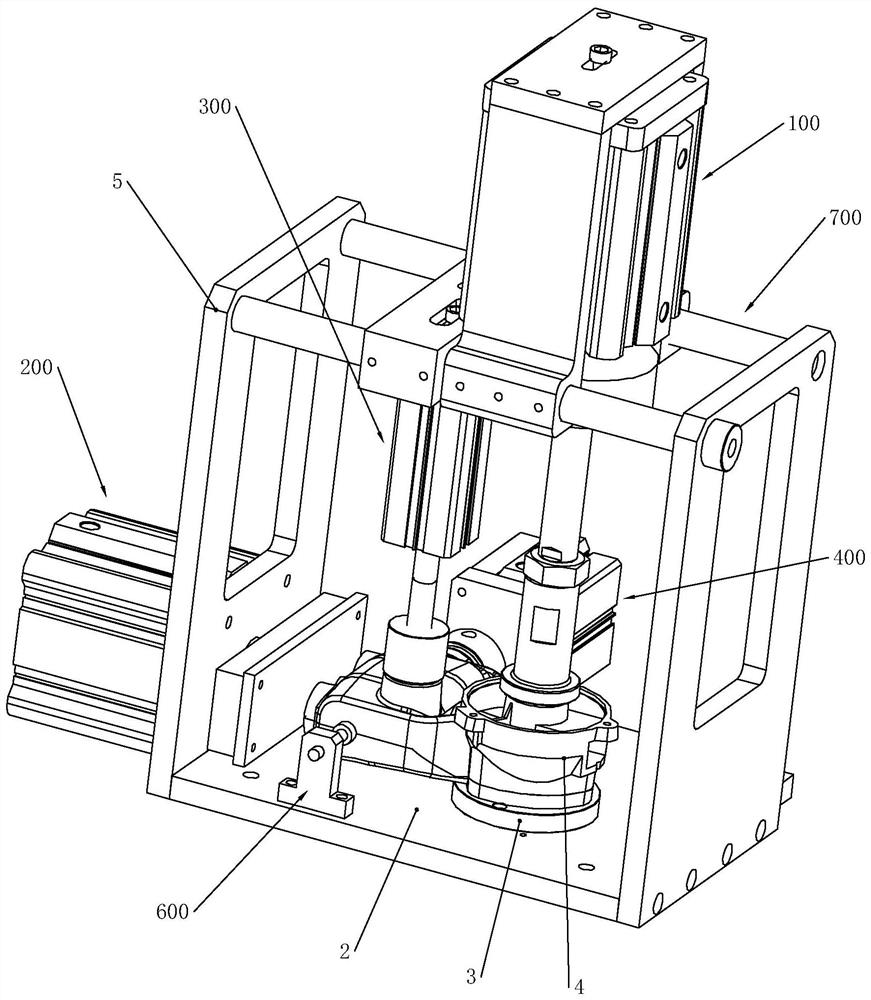

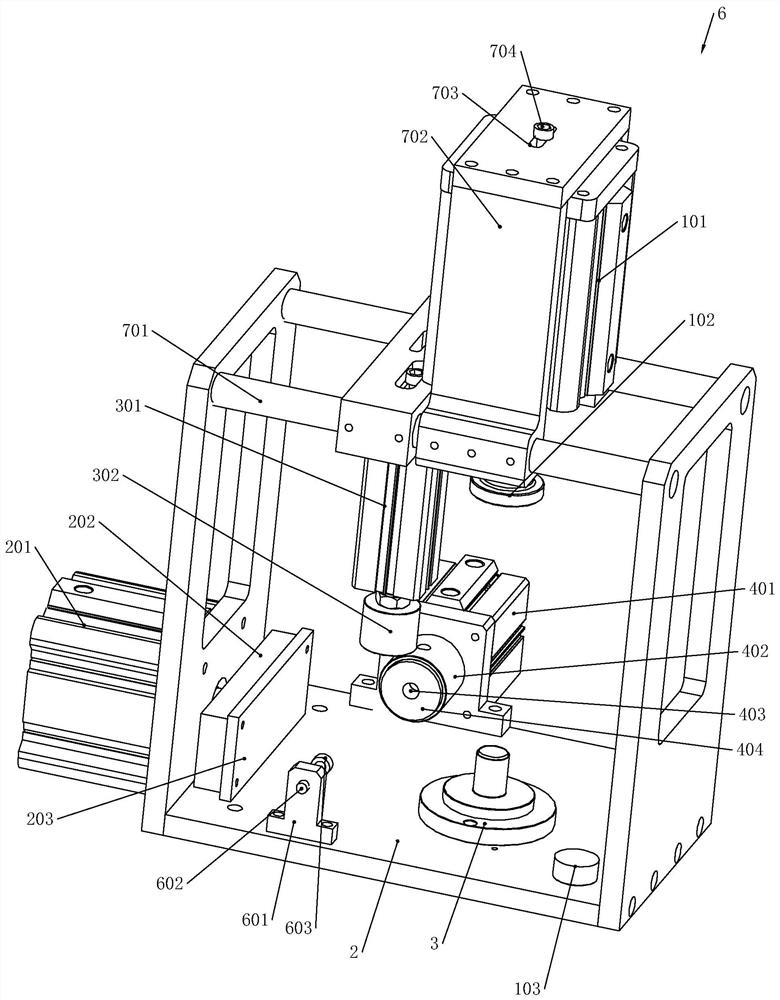

[0086] Such as figure 2 with image 3 As shown, the leak detection device 6 includes a frame 5, a pressing mechanism 100, a sealing mechanism 7, an inflation detection mechanism 400 and an adjustment mechanism 1 600; the inflation detection mechanism 400 includes an air tightness detector 500.

[0087] The sealing mechanism 7 includes a sealing assembly 1 200 and a sealing assembly 2 300

[0088] The ports of the pump body 4 mainly include port one 41, port two 42, port three 43, port four 44, and port five 45, and the ports are on different sides.

[0089] The frame 5 is installed on the body 1, the bottom of the frame 5 is a leak detection platform, a positioning die 3 is installed on the leak detection table 2 by screws, and the press...

Embodiment 2

[0115] The technical scheme of this embodiment is substantially the same as that of Embodiment 1, because the models of the pump body are different, and the pump body 4 of this embodiment is as Figure 8 shown.

[0116] Therefore, a new sealing assembly 2300 is designed for this pump body model, and the specific scheme is as follows.

[0117] Such as Figure 9-Figure 12 As shown, the sealing assembly 2 300 includes a tooling plate 305 , a positioning mandrel 306 , a balancing mandrel 307 , an adjustment plate 308 , several springs 309 and a lock ring 310 that cooperates with the spring 309 .

[0118] The tooling plate 305 is fastened on the detection table by bayonet pins, which is convenient for removal or installation. The positioning die 3 is installed on the tooling plate 305, and the structure of the positioning die 3 is slightly changed due to the difference of the pump body. Compared with the embodiment 1, the positioning die 3 has increased the overall height.

[01...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com