Nose prosthesis

A nasal prosthesis and nose dorsum technology, applied in the field of nasal prosthesis, can solve the problems of not being able to maintain a high height and collapse of the nose, and achieve the effects of reducing weight, improving softness, and good stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

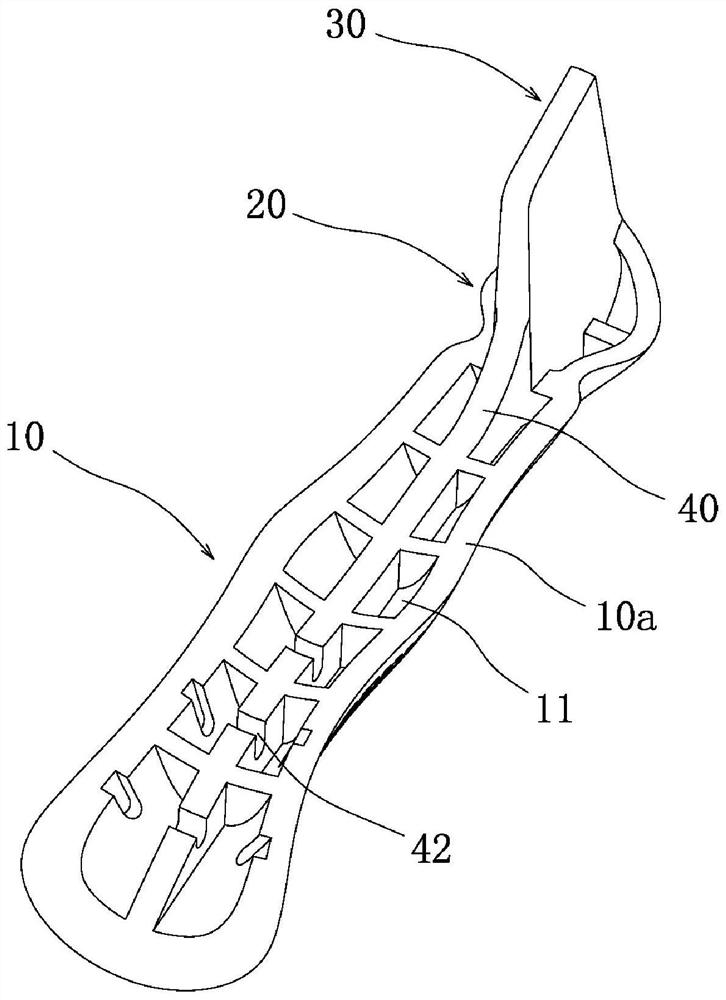

[0031] This embodiment provides a nasal prosthesis, such as figure 1 As shown in -3, it includes the dorsum part 10, the tip part 20 and the columella part 30, the dorsum part 10 is connected with the columella part 30 through the tip part 20 as a whole.

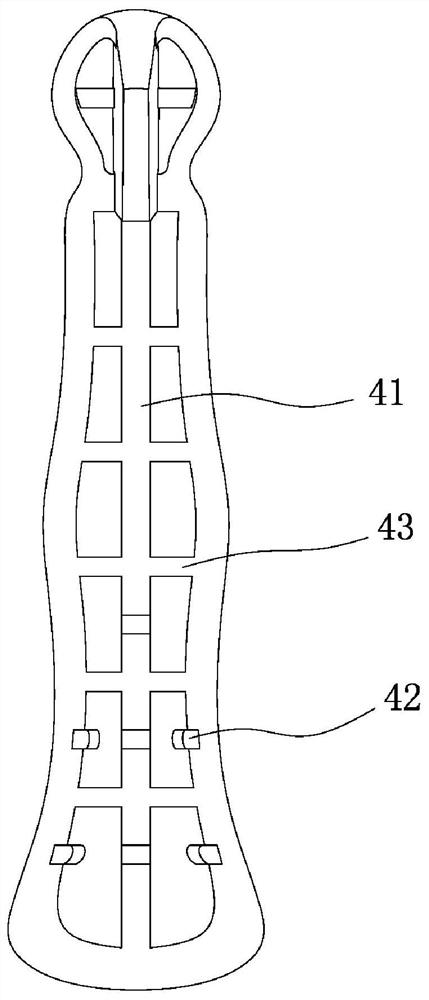

[0032] The inner surface 10a of the nasal dorsal portion 10 is recessed inwardly based on the outer surface 10b of the nasal dorsal portion 10 to form a pit 11 , wherein a support portion 40 is provided in the pit 11 .

[0033] Specifically, the back of the nose part 10 is formed into an arc shape with uniform thickness or close to uniformity, and achieves a uniform transition. The distance between the inner side 10a and the outer side 10b of the back of the nose 10 is not more than 5mm, such as 3mm, where the nose The distance between the inner side 10a and the outer side 10b of the back portion 10 does not include the thickness of the support portion 40 in the recess 11, and mainly refers to the thickness of the thin arc f...

Embodiment 2

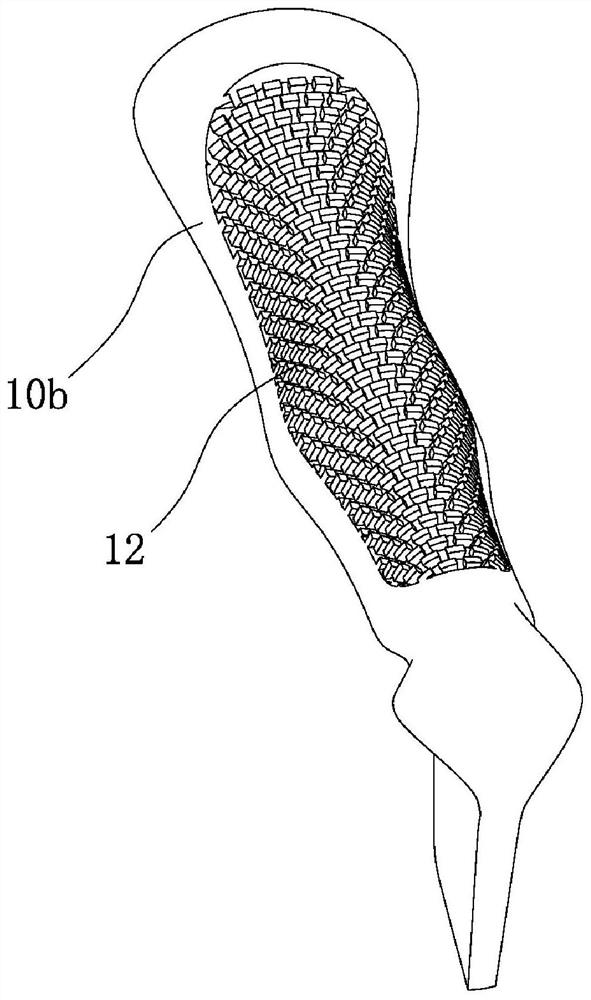

[0040] This embodiment provides a nasal prosthesis, such as Figure 4 As shown in -5, on the basis of Embodiment 1, the dorsal part of the nose 10 is provided with a through hole 13 passing through the inner surface 10a and the outer surface 10b for tissue growth to form a stable structure.

[0041] Correspondingly, a through hole 13 may also be provided on the nose tip portion 20 .

[0042] Everything not involved above is applicable to the prior art.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com