Device capable of quickly replacing and clamping for chip tube shell engraving

A chip and card mounting technology, used in positioning devices, manufacturing tools, metal processing machinery parts, etc., can solve the problems of many installation movements and poor consistency, and achieve the effect of flexible installation, light weight and strong scalability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

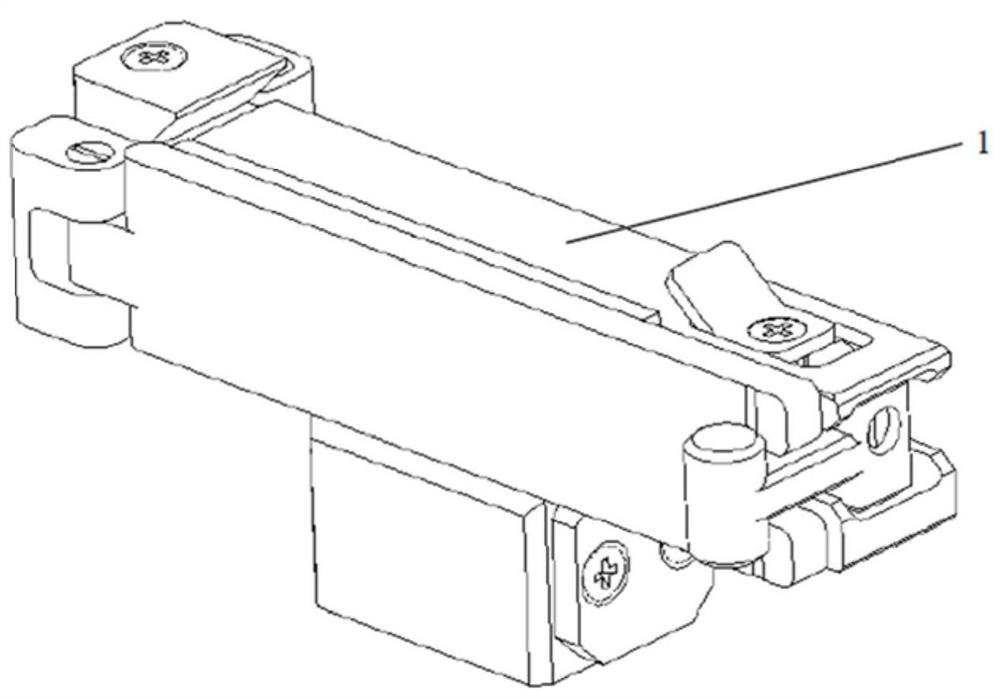

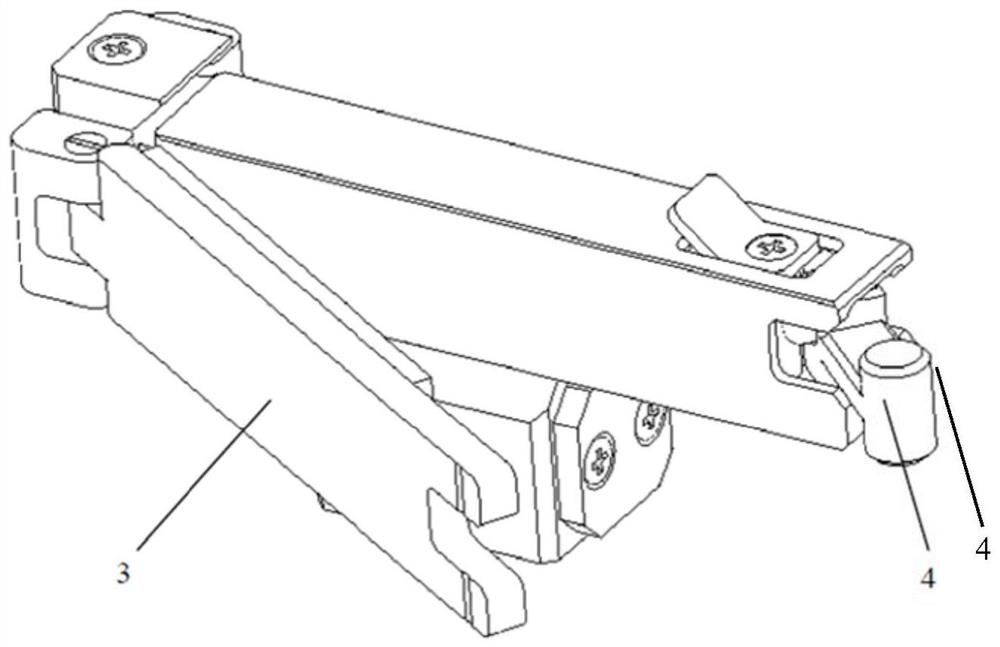

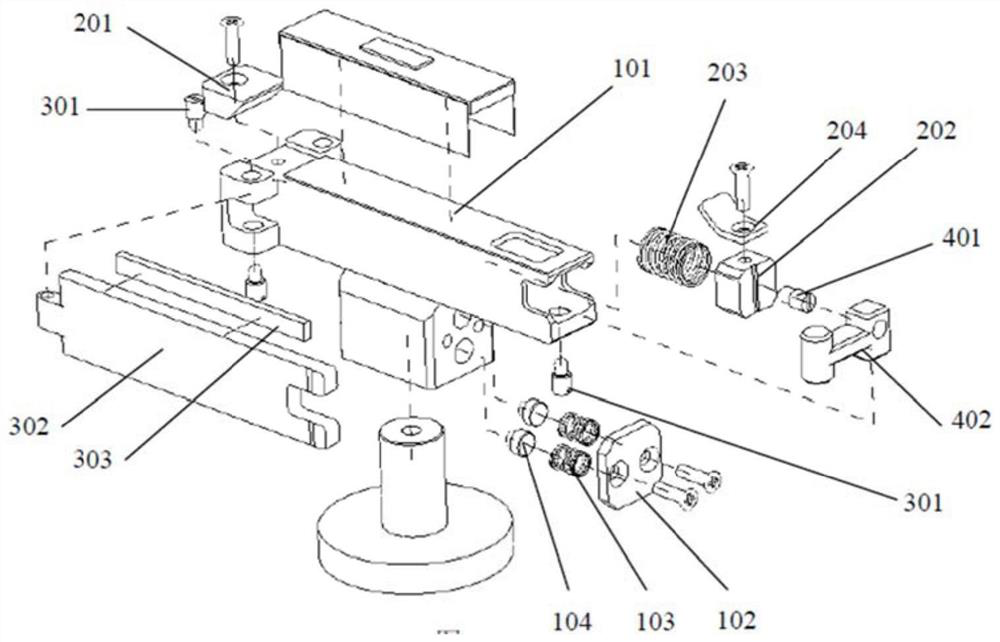

[0040] Such as figure 1 , figure 2 As shown, the present invention provides a quick replacement and clamping device for engraving chip shells, including a mounting body structure 1 , an end surface clamping structure 2 , a chip pin pressing structure 3 and a quick lock structure 4 .

[0041] Install the main structure 1, including the base and the operating table. The base and the operating table are perpendicular to each other and fixedly connected as one. The base is used to provide the installation interface with the platform shaft of the engraving machine, so that the main structure 1 is self-positioned and mechanically locked on the engraving machine platform. On the top, the console is used to place the chip. When in use, the chip shell straddles the console, and the pins on both sides are located on both sides of the console;

[0042] The clamping structure 2 on the end surface is a movable compression structure, which initially limits the length and height of the chi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com