Experimental device and method for accurately measuring core characteristic parameters of wall activation

A feature parameter, accurate measurement technology, applied in the field of refinement, can solve problems such as poor measurement accuracy, and achieve the effect of avoiding huge deviation and good scalability.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

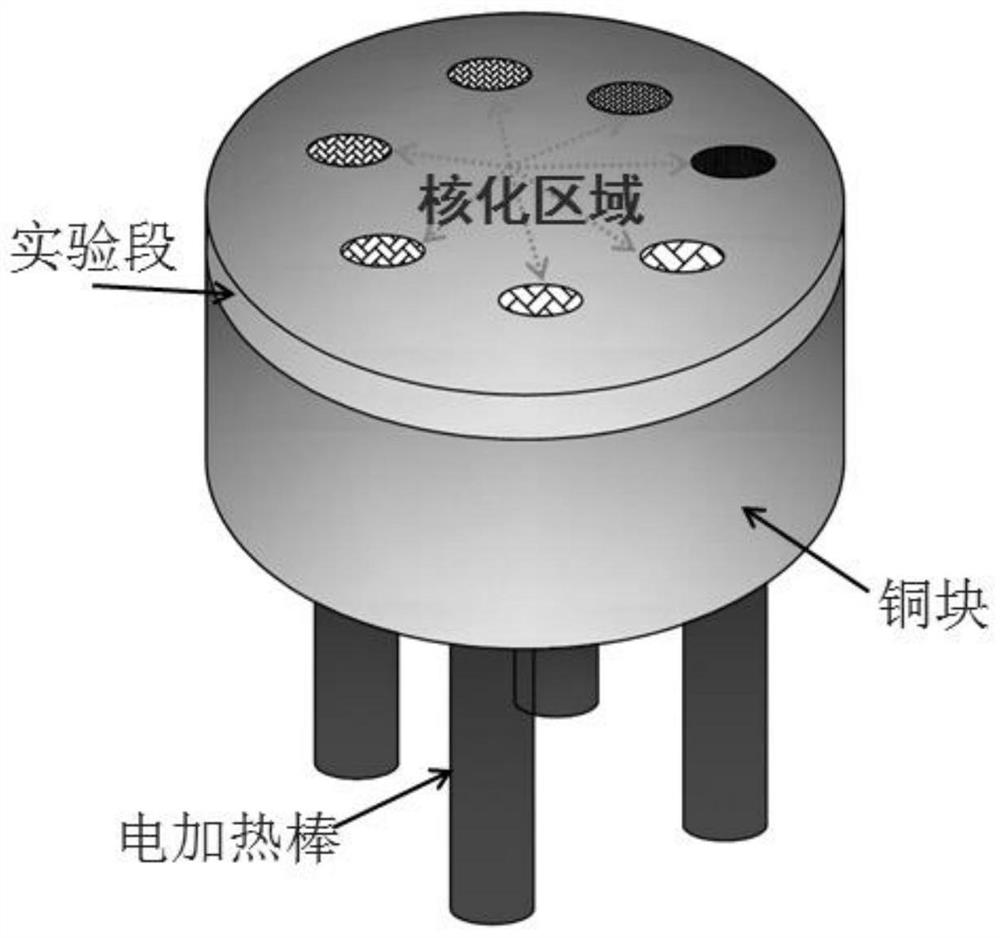

[0039] This embodiment proposes an experimental device for accurately measuring the characteristic parameters of the core of the wall surface activation. Using micro-nano processing technology, nucleated regions with different characteristic sizes are precisely processed on the same characteristic surface, and the characteristic size of the wall surface of each nucleated region is accurate. Controllable, supplemented by visualization technology, effectively avoids the huge deviation caused by the roughness characterizing the radius of the vaporization core, so as to accurately measure the characteristic parameters of the wall activation core.

[0040] Specific as figure 1 As shown, the experimental device of this embodiment is composed of an experimental section, a copper block and an electric heating rod; the experimental section is arranged on the upper end surface (upper surface) of the copper block, and the electric heating rod is arranged on the lower end surface (lower su...

Embodiment 2

[0047] This embodiment proposes an experimental method based on the experimental device proposed in the above-mentioned embodiment, specifically as Figure 4 As shown, the method includes the following steps:

[0048] Step S1, Copper Block Uniformity Design Check Calculation

[0049] Use the CFD method to calculate the upper surface temperature of the copper block with electric heating rods. At the maximum power level, the difference between the maximum and minimum temperature of the copper block upper surface does not exceed 0.5°C, which is qualified.

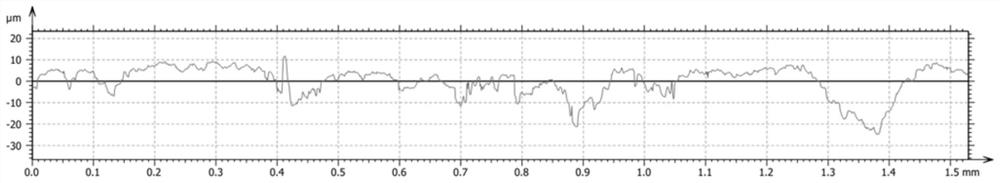

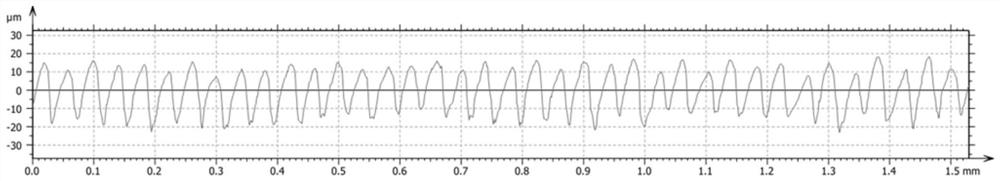

[0050] Step S2, precalculation of the feature size of the kernelized region

[0051] Before the precise measurement of the activated core feature size, the feature size needs to be pre-calculated, and the pre-calculation method can be used:

[0052]

[0053] In the formula, σ is the surface tension, v fg is the difference between the vapor-liquid two-phase volume, r c is the core feature size, p f is the liquid phase p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com