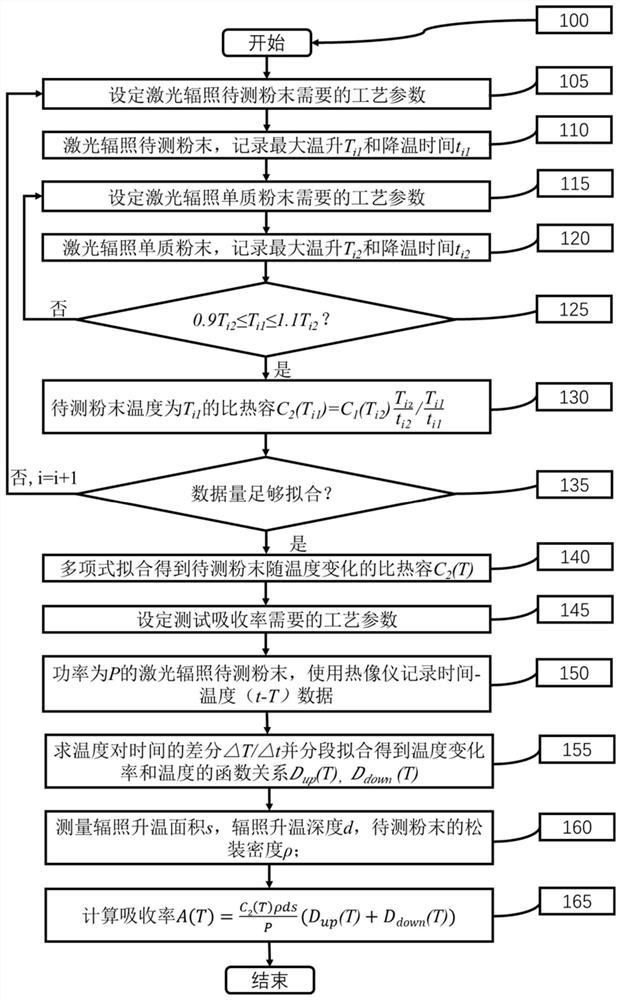

Method for measuring ultrafast laser absorptivity of powder material

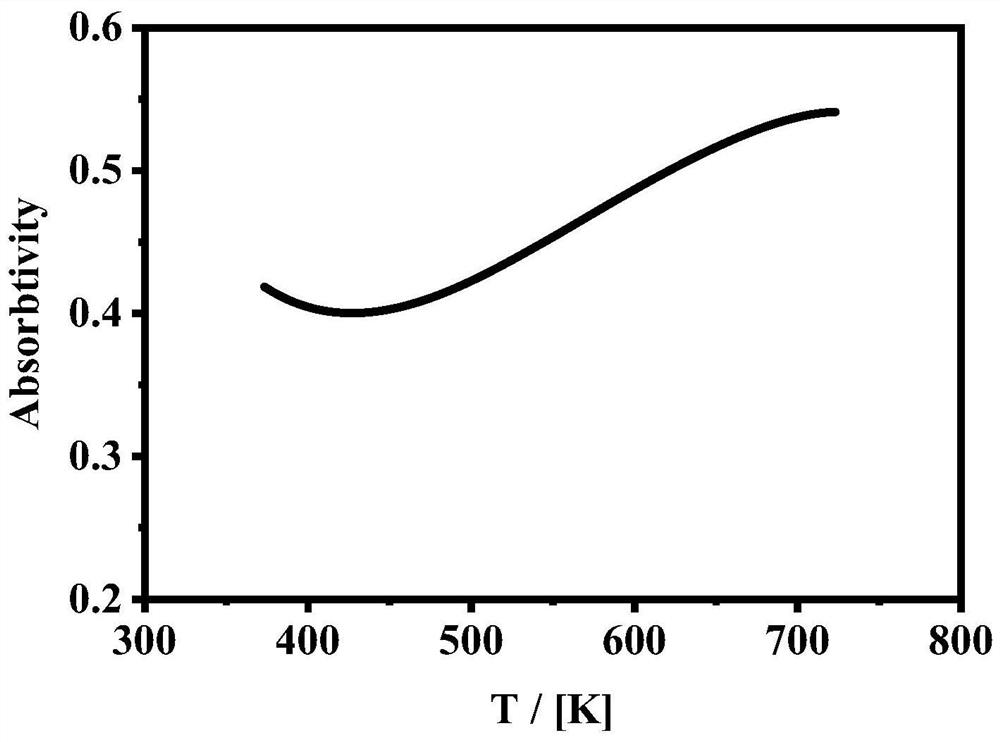

A powder material and ultrafast laser technology, which is applied in the direction of measuring devices, analyzing materials, and material thermal development, etc., can solve the problem of large error in test values, inability to provide reference for ultrafast laser absorption rate testing, inaccurate test absorption rate, etc. problems, to achieve the effect of avoiding huge deviations

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0032] The present invention is used for testing the absorptivity test of femtosecond laser NbMoTaWZr mixed powder, and the specific embodiment is:

[0033] Step 100 starts the ultrafast laser absorptivity testing method of a powder material in the present invention.

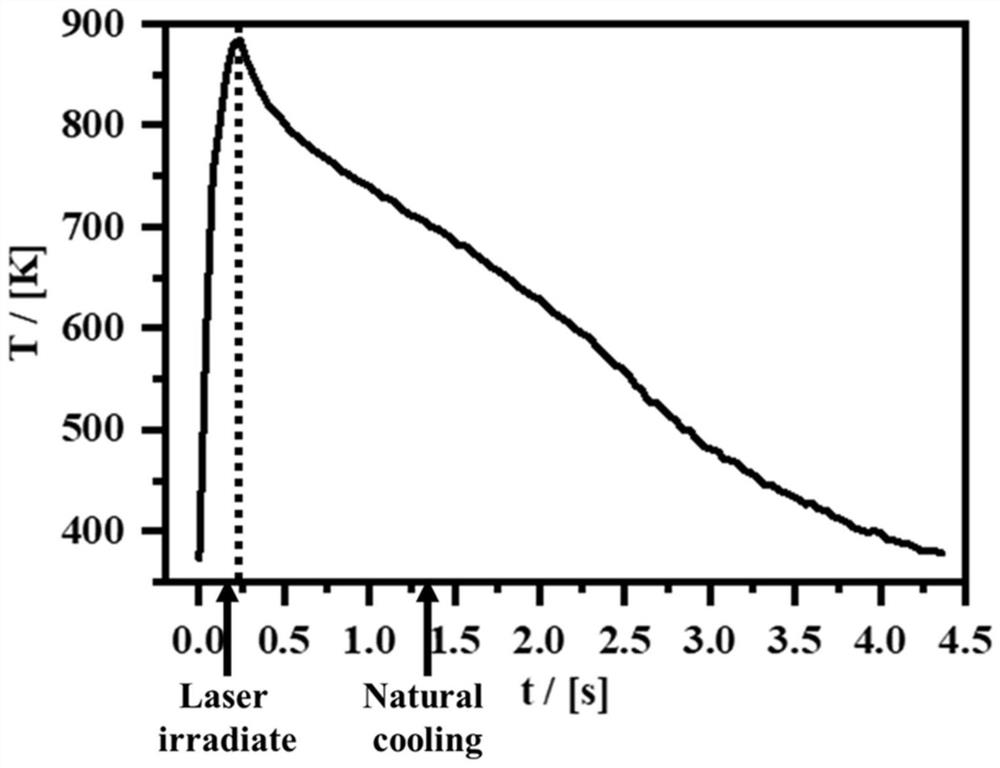

[0034] Step 105 spread the NbMoTaWZr mixed powder in the crucible and place it in the vacuum chamber, set the laser power P=9W, irradiation time t=0.15s, repetition frequency f=750kHz, defocus h=35mm, pressure D= 4000Pa, so that all parts are in working condition.

[0035] Step 110 starts laser irradiation, uses a thermal imager to test the time-temperature data from the start of irradiation to the powder cooling to room temperature, and records the maximum temperature T of laser irradiation NbMoTaWZr mixed powder i1 = 119°C and the time t required for the temperature to cool down to room temperature after the laser irradiation is stopped i1 = 0.52s.

[0036] Step 115 Take the same volume of high-purity tungs...

Embodiment 2

[0050] The present invention is used for testing the absorptivity test of femtosecond laser alumina ceramic powder, and the specific implementation method is:

[0051] Step 100 starts the method for testing the ultrafast laser absorption rate of a powder material according to the present invention

[0052] Step 105 Spread the alumina ceramic powder in the crucible and place it in the vacuum chamber, set the laser power P=20W, irradiation time t=0.2s, repetition frequency f=1mHz, defocus h=15mm, pressure D =101kPa, make each part in working condition.

[0053] Step 110 starts laser irradiation, uses a thermal imager to test the time-temperature data from the start of irradiation to the cooling of the powder to room temperature, and records the maximum temperature T of the laser irradiation alumina ceramic powder i1 = 107°C and the time t required for the temperature to cool down to room temperature after the laser irradiation is stopped i1 = 2.12s.

[0054] Step 115 spread t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| bulk density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com