Power cable and cable core alignment method and device

A power cable and cable core technology, which is applied in the field of power cable and cable core alignment methods and devices, can solve the problems of low efficiency of secondary electrical connection alignment, reduce manual labor, simplify the alignment process, and improve accuracy and work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

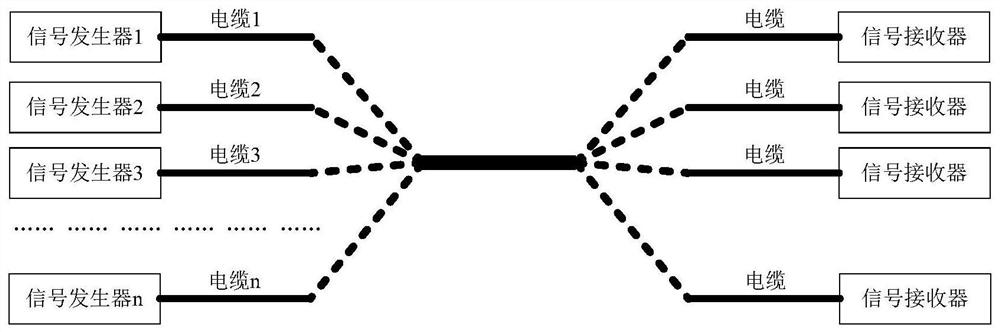

Problems solved by technology

Method used

Image

Examples

Embodiment 1

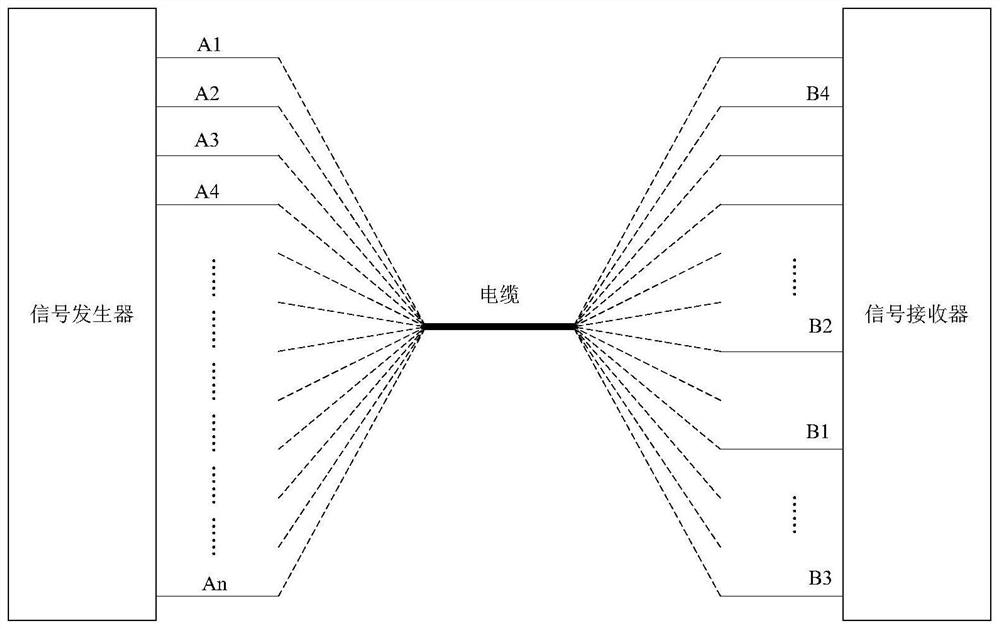

[0074] The wiring device is divided into signal generating device (14-core number T1~T14), receiving device (14-core number R1~R14), all of which have working indicator lights. When the indicator light of the occurrence port is on, it means sending a high level; when the indicator light of the receiving port is on, it means it is receiving a high level. Assume that the generator is at end A of the cable and the receiver is at end B.

[0075] The line device works periodically:

[0076] (1) In each cycle, the terminal indicator light will be fully lit m times at the same time (according to the cable number setting, in fact, at this time, the fixed T1 is set to be low and not lit to ensure that other ports form a loop to work without affecting the logical judgment. The following "full “on” means T2~T14 are all on); if the receiving device is randomly connected on the other side of the cable, its indicator lights will also be all on for m times.

[0077] (2) After all lights ar...

Embodiment 2

[0086] 1. Place the generator;

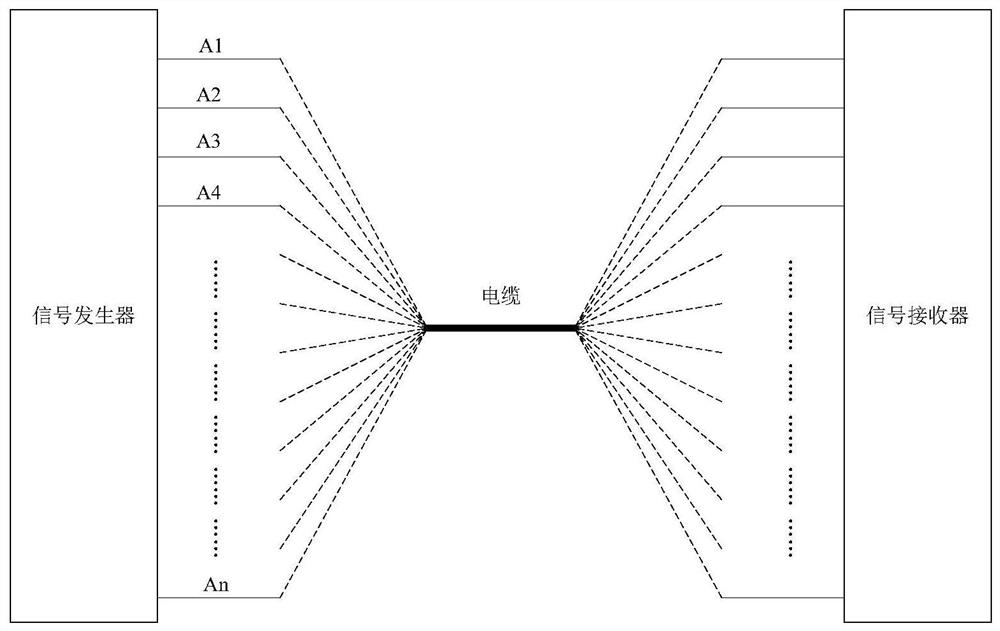

[0087] (1) Connect the A end of the cable to the generating device: mark the core of the 10-core cable, put on the sleeve and insert the cable into the cable core slots A1, A2, A3..., A14 corresponding to the generating end in sequence, And record the corresponding relationship between the bushing name and the generating end, the table is as follows:

[0088] Alignment record sheet

[0089]

[0090]

[0091] (2) Set the number of the cable: the default setting is cable No. 1 when the power is turned on, and the digital tube displays 1; if you want to mark the cable as a No. m cable (this device can be set to No. The number of times the core sends signals at the same time, so that the digital tube displays the number m. Press and hold the cable identification button again to confirm the start of the signal generation step.

[0092] When entering the signal generation step, first, the signal generation indicators of all cable cores except ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com