Punching device for intelligently manufacturing motor rotor iron core

A technology of rotor core and punching device, which is applied in the manufacture of stator/rotor body, feeding device, positioning device, etc., which can solve the problems of increasing the risk of operation, being unfavorable for transportation and post-processing, and occupying a large space

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

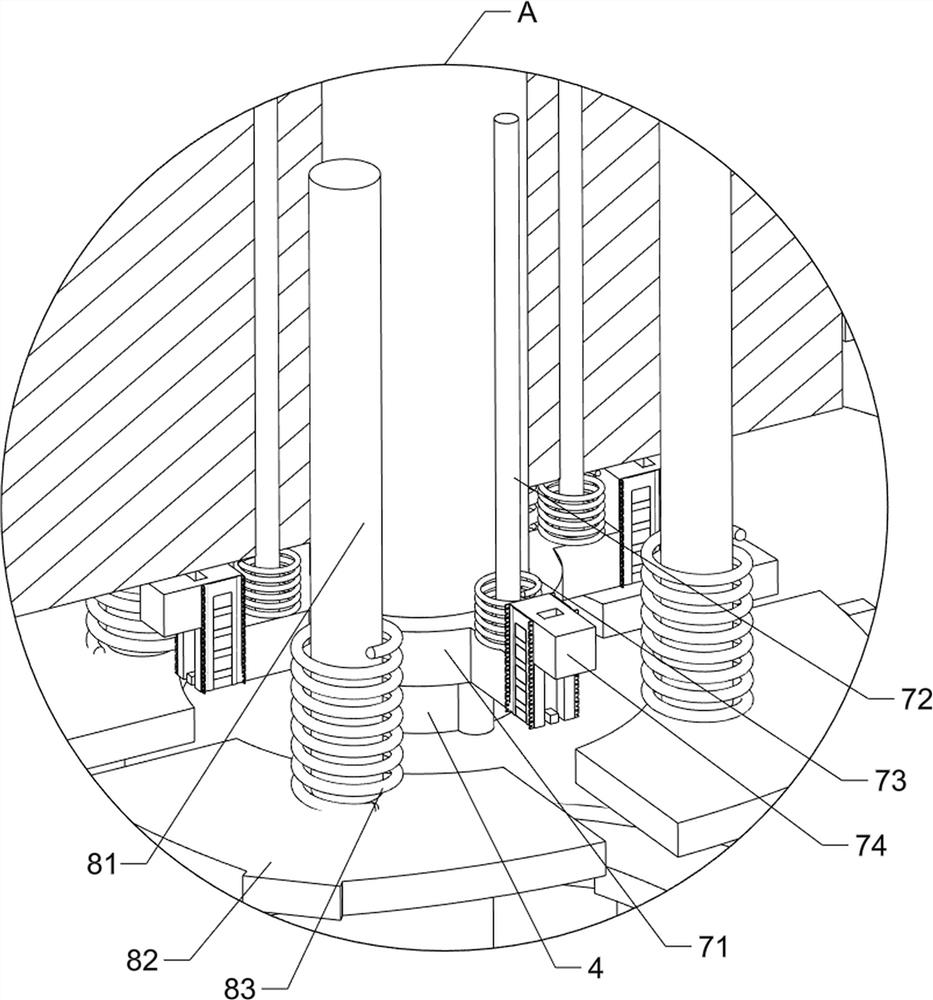

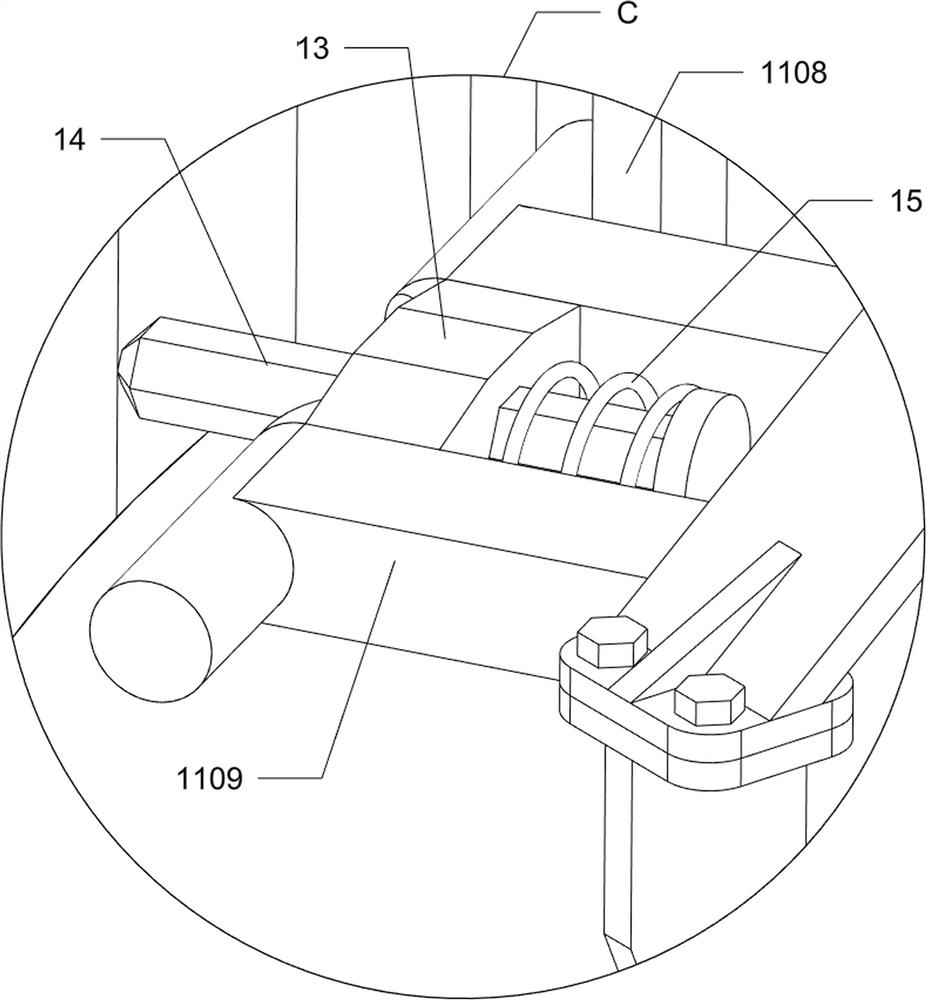

[0027] A punching device for motor rotor cores for intelligent manufacturing, such as Figure 1-4 As shown, it includes a support frame 1, a frame 2, a first connecting block 21, a cylinder 3, a stamping die 4, a support plate 5, a stamping pad 6, a pressing assembly 7 and a stamping assembly 8, and the bottom three of the frame 2 Both sides are equipped with a support frame 1, the top of the frame 2 is provided with a first connecting block 21, the upper part of the first connecting block 21 is provided with a cylinder 3, the bottom of the telescopic rod of the cylinder 3 is provided with a stamping die 4, and the upper part of the frame 2 is provided with a support The plate 5 and the support plate 5 are placed with a stamping block 6 , a primary pressing assembly 7 is connected between the stamping die 4 and the first connecting block 21 , and a stamping assembly 8 is arranged between the stamping die 4 and the first connecting block 21 .

[0028] The primary compression as...

Embodiment 2

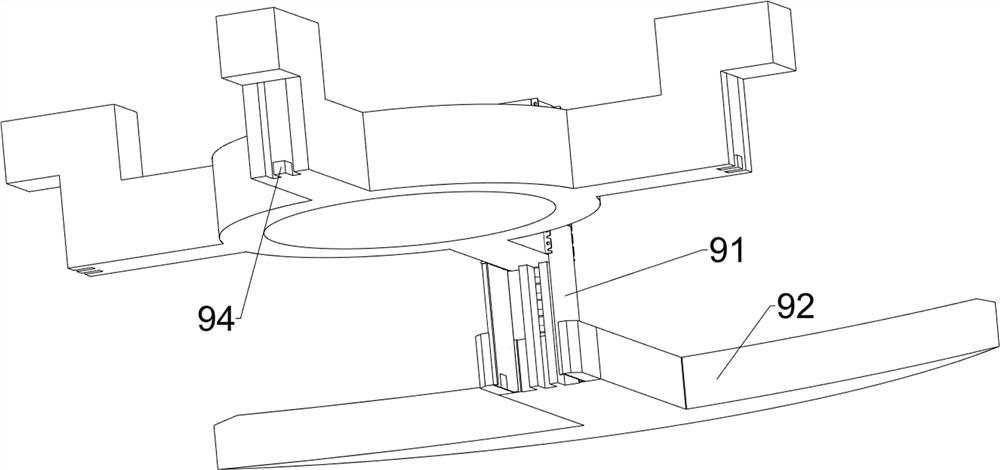

[0032] On the basis of Example 1, such as Figure 5-9 As shown, a secondary pressing assembly 9 is also included, and the secondary pressing assembly 9 includes a guide sleeve 91, a T-shaped block 92, a third spring 93 and a second limit block 94, and the bottom of the L-shaped guide block 74 is provided with There is a third spring 93, the bottom of the third spring 93 is provided with a T-shaped block 92, the top of the T-shaped block 92 is provided with two guide sleeves 91, and the two guide sleeves 91 are slidably connected with the L-shaped guide block 74. Second limiting blocks 94 are provided on four sides of the collar 71 .

[0033] When the L-shaped guide block 74 and the second limit block 94 move downward, the third spring 93 is compressed, so that the guide sleeve 91 and the T-shaped block 92 move downward, and the T-shaped block 92 clamps and fixes the material. The L-shaped guide block 74 and the second limit block 94 move upwards and reset, and the third sprin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com