A bottle automatic straightening device for food filling

An automatic straightening and filling technology, applied in transportation and packaging, rollers, conveyor objects, etc., can solve problems such as affecting production efficiency, low efficiency, and large manpower.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

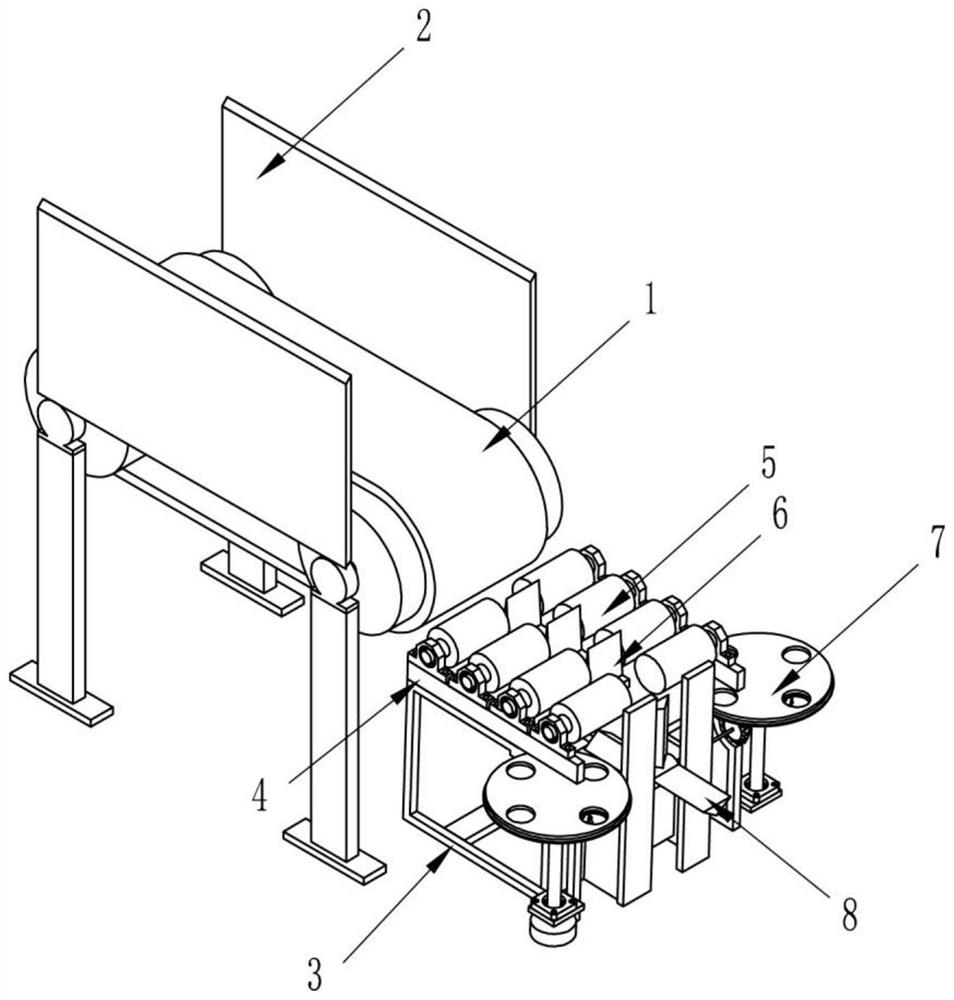

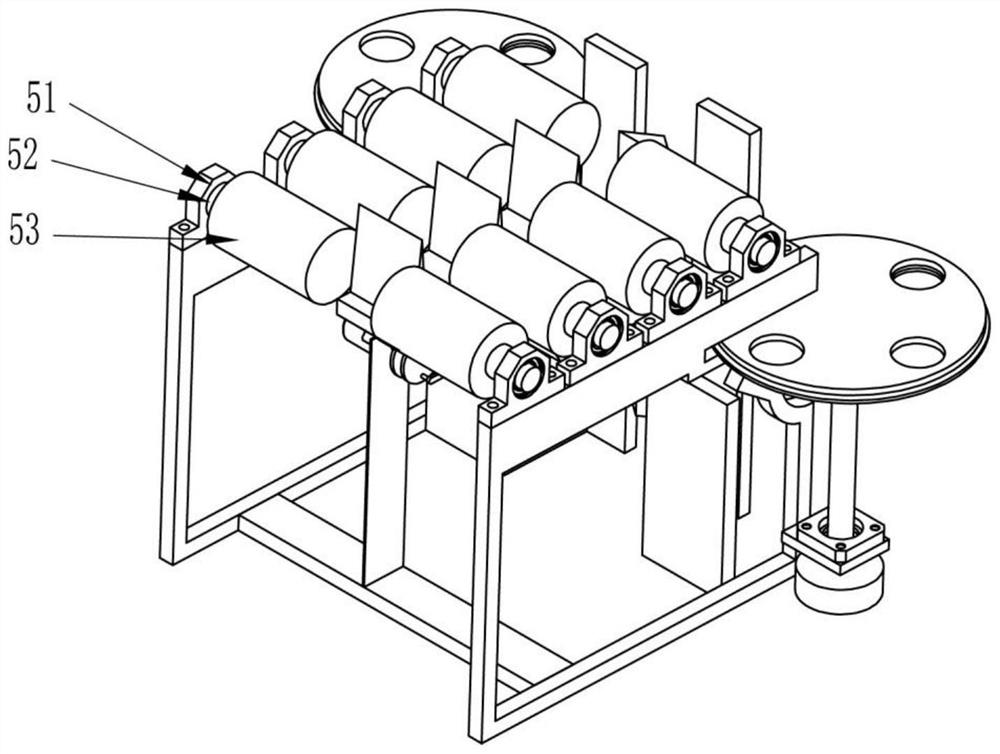

[0021] An automatic bottle straightening device for food filling, such as Figure 1-2 As shown, it includes a belt conveyor 1, a belt baffle 2, a frame 3, a support rod 4, a single discharge mechanism 5, a single conveying mechanism 6, a disc conveying mechanism 7 and a vertical bottle mechanism 8, and the belt conveyor 1 is fixedly installed on both sides. There is a belt baffle 2, a frame 3 is installed on the right part of the belt conveyor 1, support rods 4 are installed on the front and rear sides of the upper part of the frame 3, a single discharge mechanism 5 is fixedly installed on the upper part of the support rod 4, and a single delivery mechanism 5 is installed in the middle of the frame 3. Mechanism 6, single transport mechanism 6 is positioned at single discharge mechanism 5 just below, and frame 3 right portion front and rear sides are equipped with disc transport mechanism 7, and frame 3 right portion middle is equipped with vertical bottle mechanism 8.

[0022]...

Embodiment 2

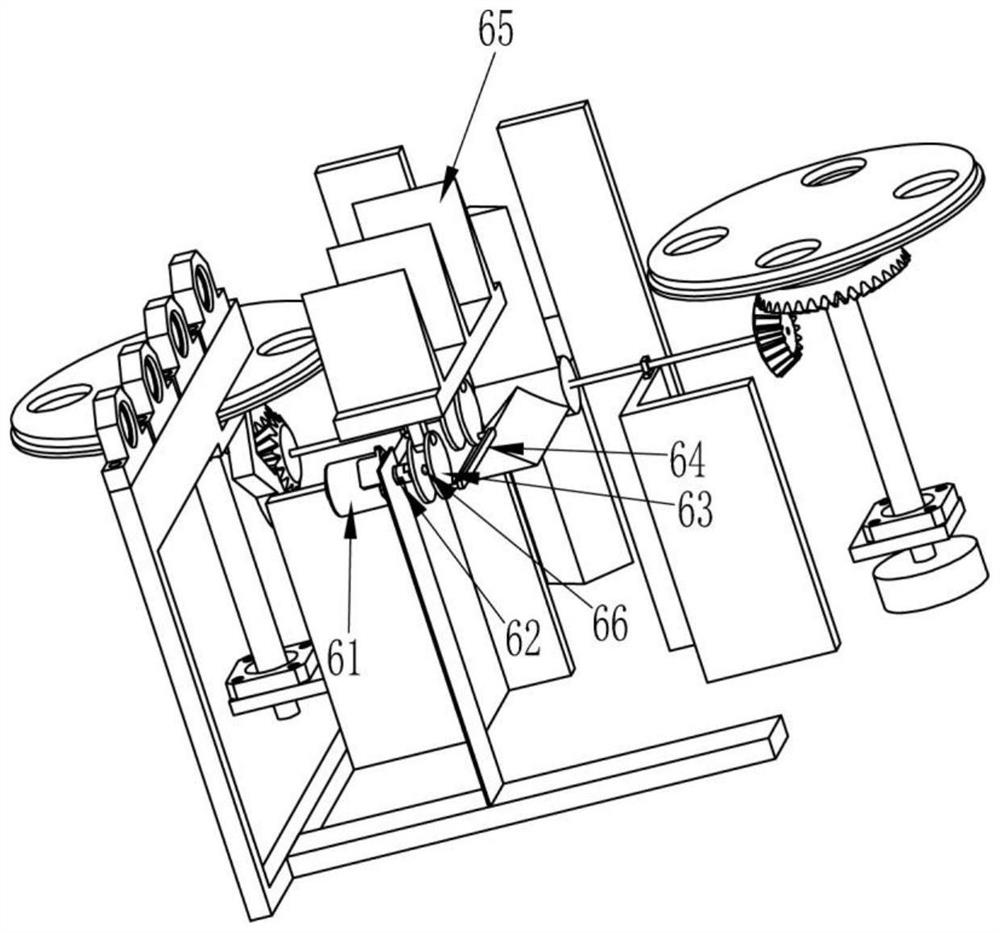

[0026] On the basis of embodiment 1, a kind of bottle automatic straightening device for food filling, such as image 3 As shown, a single transport mechanism 6 includes a motor 61, a shaft coupling 62, a transport disc 63, a connecting rod 64, a discharge plate 65 and a transport shaft 66, and the motor 61 is fixedly installed by bolts in the middle of the frame 3, and the motor 61 passes The coupling 62 is equipped with a transport shaft 66, on which a transport disc 63 is installed by welding, and a discharge plate 65 is installed in the transport disc 63 through a pin rotation, and a pin rotation is used between the discs. A connecting rod 64 is provided.

[0027] Manually start the motor 61 to rotate, and the motor 61 drives the transport disc 63 to rotate through the coupling 62, and the transport disc 63 rotates to drive the discharge plate 65 to make a circular motion around a center of a circle. Discharge the distance of the roller 53 to complete the transport work. ...

Embodiment 3

[0029] On the basis of embodiment 2, a kind of bottle automatic straightening device for food filling, such as Figure 4-5 Shown, the disc delivery mechanism 7 includes a hydraulic motor 71, a disc bearing 72, a disc rotating shaft 73, a disc baffle plate 74 and a rotating disc 75, and the frame 3 is equipped with a disc bearing 72 by a bearing seat, and the circle The disc shaft 73 is installed in the disc bearing 72 through an interference connection, the lower part of the disc shaft 73 is equipped with a hydraulic motor 71 through the coupling 62, and the top of the disc shaft 73 is fixedly installed with a rotating disc 75, and the rotating disc 75 Have four bottle transportation holes 76 along the circumferential direction, the frame 3 is fixedly equipped with a disk baffle 74, and a drop hole 77 is arranged on the disk baffle 74, and the position radius of the drop hole 77 is the same as that of the bottle transportation. Holes 76 are equal.

[0030] Manually start the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com