The clamping device for clamping the enzyme plate in the chemiluminescence immunoassay analyzer

A chemiluminescence immune and clamping device technology, applied in the field of clamping devices, can solve the problems of long time, can not be automatically adjusted, affect the analysis results, etc., to achieve easy opening and closing, good sealing, and reduce leakage. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

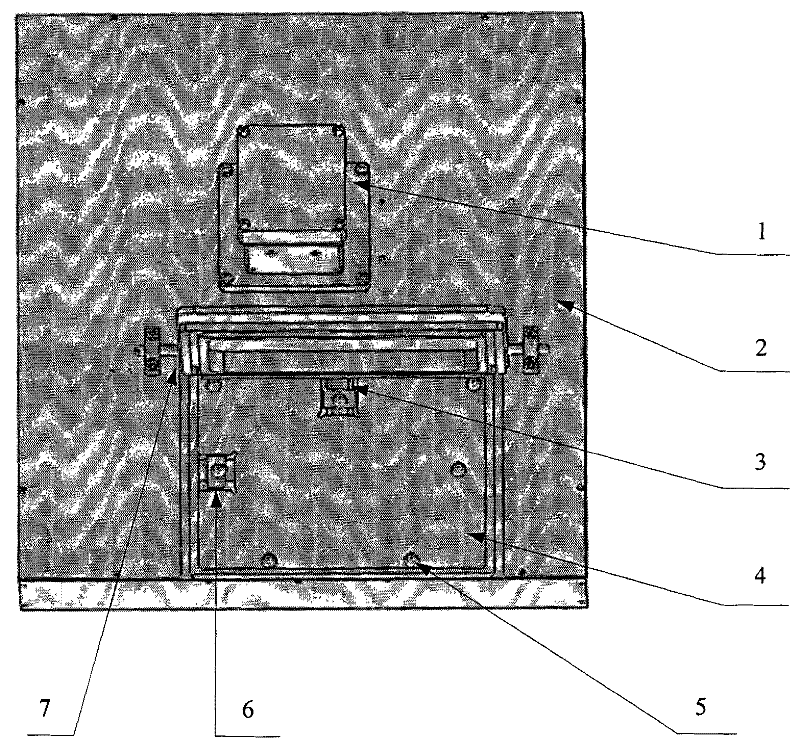

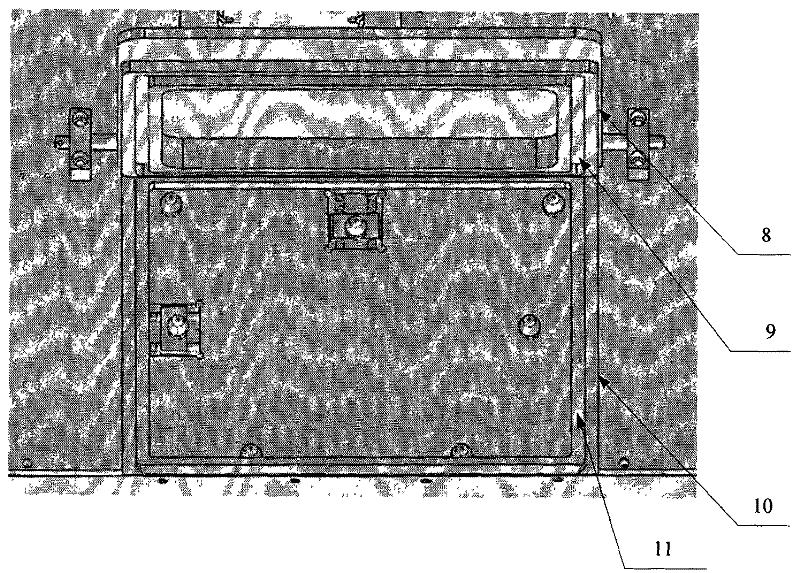

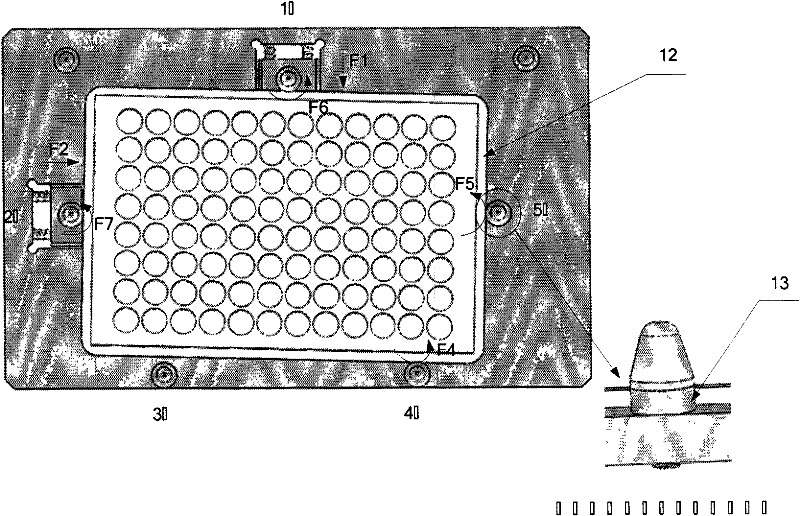

[0017] The names of the components shown in the accompanying drawings are as follows:

[0018] 1. Photon counting probe 2, box body 3, spring and polished rod 4, tray 5, positioning pin 6, slider 7, flip door 8, boss of flip door 9, back-shaped sealing groove of flip door 10, box door frame The groove 11, the edge of the box door frame 12, the microplate 13, the bearing

[0019] figure 1 It is the appearance diagram of the invention. The outer surface of the box body 2 is treated with matt black, and its top surface is provided with a circular opening for installing the photon counting probe 1. One side of the top surface is provided with a flip door 7 for taking and placing enzymes. Standard plate; there is a clamping device inside the box for clamping and automatically aligning the microplate.

[0020] Such as figure 2 As shown, the inwall of the flip door 7 is provided with a return-shaped sealing groove 9 and a boss 8, and the three sides of the door frame are provided...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com