Control method of four-axis mechanical arm for grabbing explosives

A technology for robotic arms and explosives is applied in the control field of four-axis robotic arms, which can solve the problems of complex and unintuitive operation, and achieve the effect of reducing the difficulty of operation, simplicity of automation, and reduction of computing time.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0034] The present invention will be described in detail below with reference to the accompanying drawings and examples.

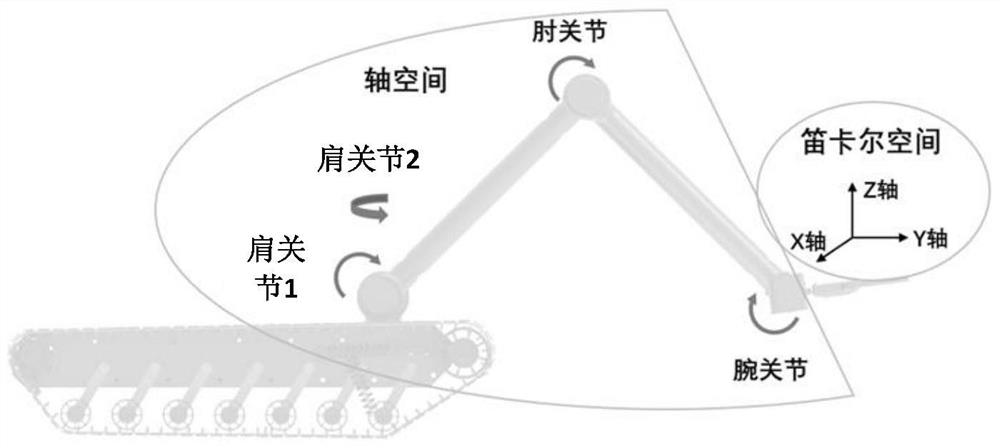

[0035] The invention provides a method for controlling a four-axis robotic arm for grabbing explosives. The four-axis robotic arm includes four joints, which are respectively the first shoulder joint, the second shoulder joint, the elbow joints and wrist joints, wherein the first shoulder joint is connected to the platform, the flow of the control method is as follows Figure 6 shown, including the following steps:

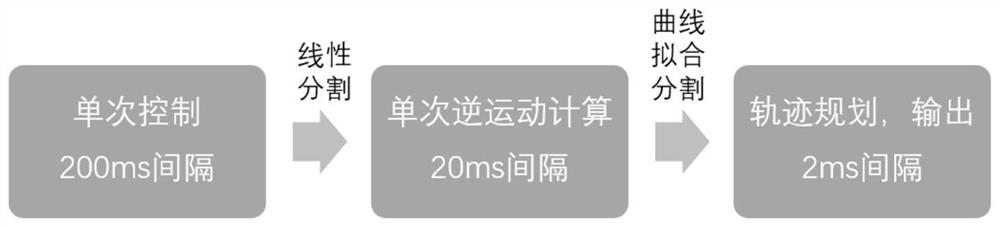

[0036] Step 1. According to the initial position P of the end of the robot arm 1 and the target point P 2 , for line segment P 1 P 2 Carry out the average division of the position points, the divided position points and P 1 ,P 2 Makes up the end trajectory of the robotic arm.

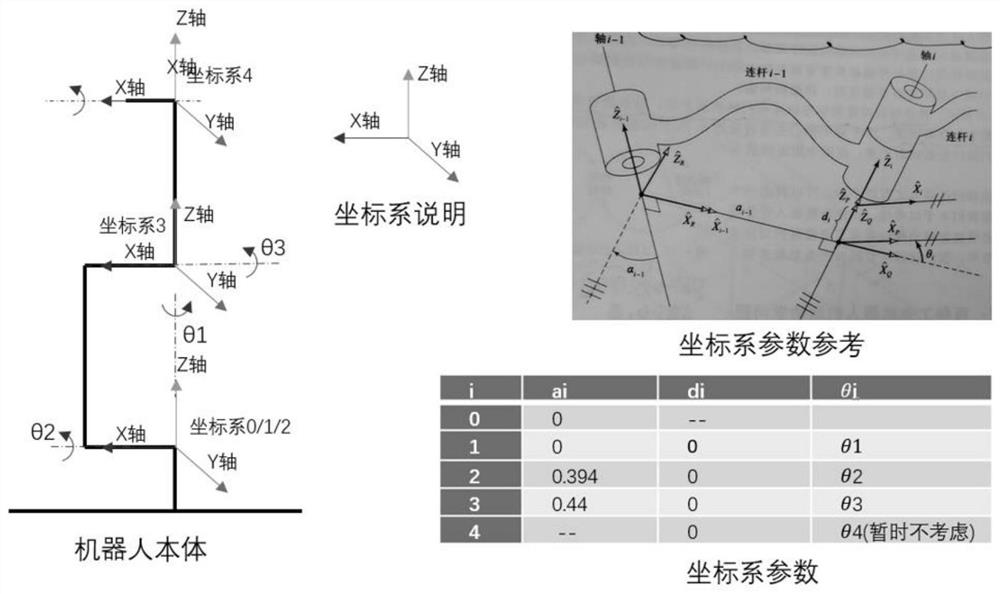

[0037] Step 2. Obtain the coordinates (px py pz) of the end position of the robotic arm in sequence, and use the inverse motion calculation process to calculate ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com