Laser glass containing silver nanoparticles and its manufacturing method

A technology of laser glass and silver nano, which is applied in the field of laser glass

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0109] In order to further clearly illustrate and illustrate the technical solution of the present invention, the following non-limiting examples are provided. Efforts have been made to ensure accuracy with respect to values (eg, amounts, temperature, etc.) in the embodiments of the invention, but some errors and deviations must be accounted for.

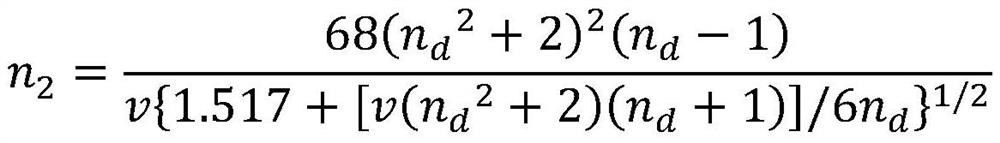

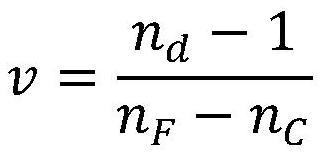

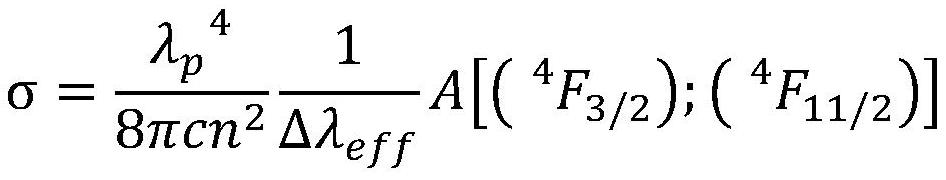

[0110] In Examples 1 to 14, glass compositions having the components shown in Table 1 to Table 2 were obtained by using the manufacturing method of the above glass composition. Examples 15-28 in Table 3-Table 4 adopt the glass compositions of the components shown in Examples 1-14, and obtain silver-containing nano-particle laser glass through the manufacturing method of silver-containing nano-particle laser glass, and adopt the above-mentioned test Methods To test the properties of laser glass containing silver nanoparticles.

[0111] Table 1.

[0112]

[0113]

[0114] Table 2.

[0115]

[0116] table 3.

[0117] ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| wavelength | aaaaa | aaaaa |

| refractive index | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com