Erbium doped bismuth borate glass and prepaation process thereof

An erbium bismuth borate and glass technology, applied in the field of laser glass, can solve the problems of low luminous quantum efficiency and the like

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example 1

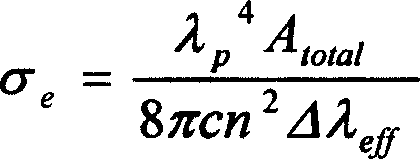

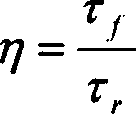

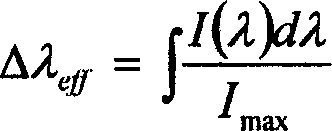

[0019] Example 1: the purity after drying is analytically pure H 3 BO 3 、 Bi 2 o 3 and Er with a purity greater than 99.99% 2 o 3 Powder, according to 0.1Er 2 o 3 : 99.9(45Bi 2 o 3 :55B 2 o 3 ) (molar ratio) ratio Accurately weigh raw materials. After the raw materials are ground and mixed evenly in an agate grinding disc, they are poured into a platinum crucible, and then placed in a temperature-controllable resistance furnace for melting at about 900°C for 10 hours. During the melting process, a stirring rod made of platinum was used to continuously stir the melt at a rate of 30 revolutions per minute. Then pour the molten liquid into a brass mold of a specific shape that has been preheated to 400°C, put it in an annealing furnace and keep it warm for 3 hours, and then anneal the glass sample at a cooling rate of about 35°C per hour. After the obtained glass sample was polished, the measured stimulated emission cross section was about 0.94×10 -20 cm 2 , the lum...

example 2

[0020] Example 2: the purity after drying is analytically pure H 3 BO 3 、 Bi 2 o 3 and Er with a purity greater than 99.99% 2 o 3 Powder, according to 0.5Er 2 o 3 : 99.5(45Bi 2 o 3 :55B 2 o 3 ) (molar ratio) ratio Accurately weigh raw materials. After the raw materials are ground and mixed evenly in an agate grinding disc, they are poured into a platinum crucible, and then placed in a temperature-controllable resistance furnace for melting at about 900°C for 10 hours. During the melting process, a stirring rod made of platinum was used to continuously stir the melt at a rate of 30 revolutions per minute. Then pour the molten liquid into a brass mold of a specific shape that has been preheated to 400°C, put it in an annealing furnace and keep it warm for 3 hours, and then anneal the glass sample at a cooling rate of about 35°C per hour. After the obtained glass sample is polished, the measured stimulated emission cross section is about 0.71×10 -20 cm 2 , the lumin...

example 3

[0021] Example 3: the purity after drying is analytically pure H 3 BO 3 、 Bi 2 o 3and Er with a purity greater than 99.99% 2 o 3 Powder, according to 0.1Er 2 o 3 : 99.9(25Bi 2 o 3 : 75B 2 o 3 ) (molar ratio) ratio Accurately weigh raw materials. The raw materials are ground and mixed evenly in an agate grinding disc, poured into a platinum crucible, and then placed in a temperature-controllable resistance furnace for melting at about 950°C for 13 hours. During the melting process, a stirring rod made of platinum was used to continuously stir the melt at a rate of 30 revolutions per minute. Then pour the molten liquid into a brass mold of a specific shape that has been preheated to 450°C, put it in an annealing furnace and keep it warm for 4 hours, and then anneal the glass sample at a cooling rate of about 40°C per hour. After the obtained glass sample was polished, the measured stimulated emission cross section was about 0.72×10 -20 cm 2 , the luminous quantum e...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com