Neodymium doped borate glass with high luminous quantum efficiency and its preparing method

A technology of luminous quantum and neodymium borate, which is applied to furnace types, furnaces, boilers, etc., and can solve problems such as low luminous quantum efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example 1

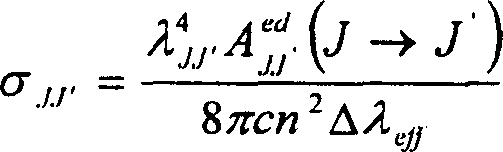

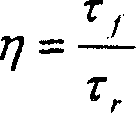

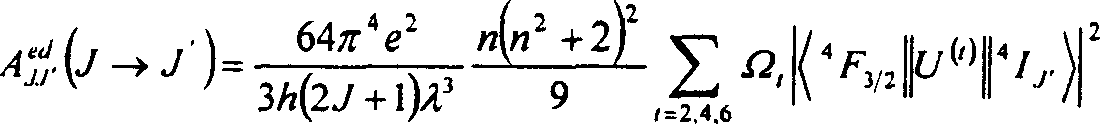

[0017] Example 1: the purity after drying is analytically pure H 3 BO 3 、 Bi 2 o 3 and Al 2 o 3 and Nd with a purity greater than 99.99% 2 o 3 Powder, according to 0.5Nd 2 o 3 : 99.5(40Bi 2 o 3 : 15Al 2 o 3 :45B 2 o 3 ) (molar ratio) ratio Accurately weigh raw materials. After the raw materials are ground and mixed evenly in an agate grinding disc, they are poured into a platinum crucible, and then placed in a temperature-controllable resistance furnace for melting at about 1000°C for 13 hours. During the melting process, a stirring rod made of platinum was used to continuously stir the melt at a rate of 30 revolutions per minute. Then pour the molten liquid into a brass mold of a specific shape that has been preheated to 500°C, put it in an annealing furnace and keep it warm for 4 hours, and then anneal the glass sample at a cooling rate of about 45°C per hour. After the obtained glass sample was polished, the measured stimulated emission cross section was abo...

example 2

[0018] Example 2: the purity after drying is analytically pure H 3 BO 3 、 Bi 2 o 3 and Al 2 o 3 and Nd with a purity greater than 99.99% 2 o 3 Powder, according to 1Nd 2 o 3 :99(40Bi 2 o 3 : 10Al 2 o 3 :50B 2 o 3 ) (molar ratio) ratio Accurately weigh raw materials. After the raw materials are ground and mixed evenly in an agate grinding disc, they are poured into a platinum crucible, and then placed in a temperature-controllable resistance furnace for melting at about 900°C for 13 hours. During the melting process, a stirring rod made of platinum was used to continuously stir the melt at a rate of 30 revolutions per minute. Then pour the molten liquid into a brass mold of a specific shape that has been preheated to 450°C, put it in an annealing furnace and keep it warm for 4 hours, and then anneal the glass sample at a cooling rate of about 45°C per hour. After the obtained glass sample was polished, the measured stimulated emission cross section was about 3.9...

example 3

[0019] Example 3: the purity after drying is analytically pure H 3 BO 3 、 Bi 2 o 3 and MgCO3 and Nd with a purity greater than 99.99% 2 o 3 Powder, according to 0.5Nd 2 o 3 : 99.5(40Bi 2 o 3 :5MgO:55B 2 o 3 ) (molar ratio) ratio Accurately weigh raw materials. After the raw materials are ground and mixed evenly in an agate grinding disc, they are poured into a platinum crucible, and then placed in a temperature-controllable resistance furnace for melting at about 950°C for 10 hours. During the melting process, a stirring rod made of platinum was used to continuously stir the melt at a rate of 40 revolutions per minute. Then pour the molten liquid into a brass mold of a specific shape that has been preheated to 450°C, put it in an annealing furnace and keep it warm for 3 hours, and then anneal the glass sample at a cooling rate of about 30°C per hour. After the obtained glass sample is polished, the measured stimulated emission cross section is about 4.4×10 -20 cm ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com