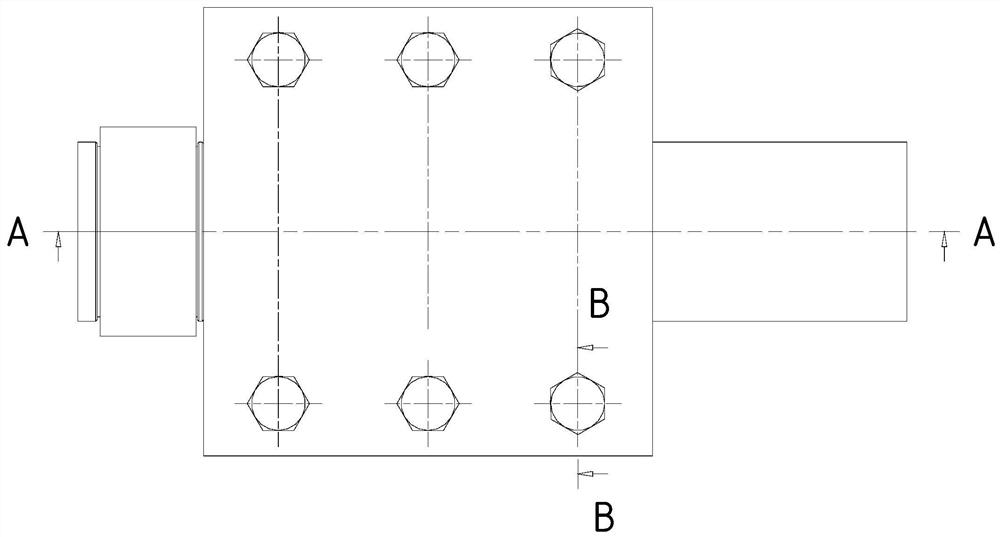

Maintenance-free transverse moving bearing seat with vibration reduction and automatic aligning functions

A self-aligning, bearing seat technology, applied in the direction of shafts and bearings, sliding contact bearings, bearing components, etc., can solve the problems of inconvenient maintenance and limited installation space

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

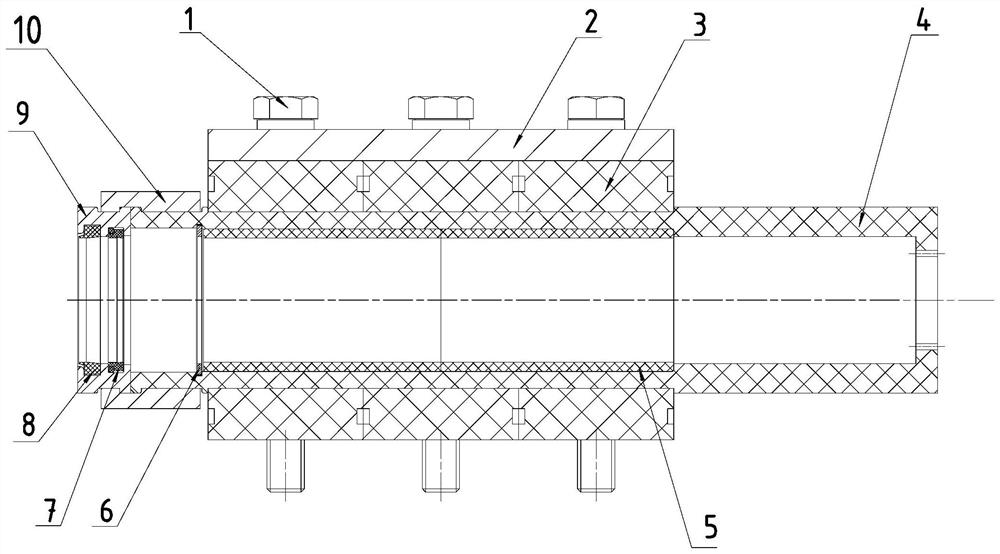

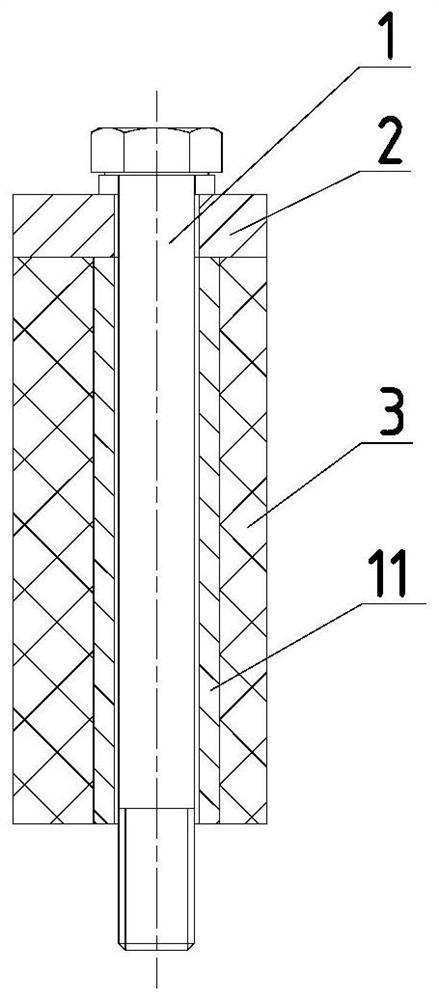

[0052] As shown in the figure, the sleeve 4 is installed in the inner hole of the rubber blocks 3, and the three rubber blocks 3 are connected in series, and the sleeve 4 and the rubber blocks 3 cannot have relative movement.

[0053] The linear bearing 5 is installed in the inner hole of the sleeve 4, and there is no relative movement with the sleeve 4.

[0054] One side end surface of the linear bearing 5 is in contact with the sleeve 4, and the other side is in contact with the end surface of the elastic circlip 6, and the elastic circlip 6 is installed in the groove of the inner hole of the sleeve 4, so that the linear bearing 5 moves along the axial direction. Inability to exercise.

[0055] There are two grooves on the inner hole of the dust-proof cover 9, and the dust-proof ring A7 and the dust-proof ring B8 are installed in these two grooves respectively.

[0056] The fixed sleeve 10 is made up of two half-rings, and there is a groove on the inner hole, and the dustpr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com