Iron-manganese-based positive electrode material, preparation method and application thereof

A cathode material, iron-manganese-based technology, applied in the field of iron-manganese-based cathode materials and their preparation, can solve problems such as poor first-efficiency of iron-manganese-based cathode materials, and achieve the effects of improving electrical performance, first effect and cycle performance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

[0035] According to another typical embodiment of the present application, a method for preparing an iron-manganese-based positive electrode material, the preparation method includes: combining an inorganic compound of lithium and Fe x mn y (OH) 2 The precursor is oxidized and sintered to obtain an iron-manganese-based positive electrode material, wherein, 0x mn y (OH) 2 The ratio of the total molar amounts of Fe and Mn in the precursor is 0.1:1˜0.5:1.

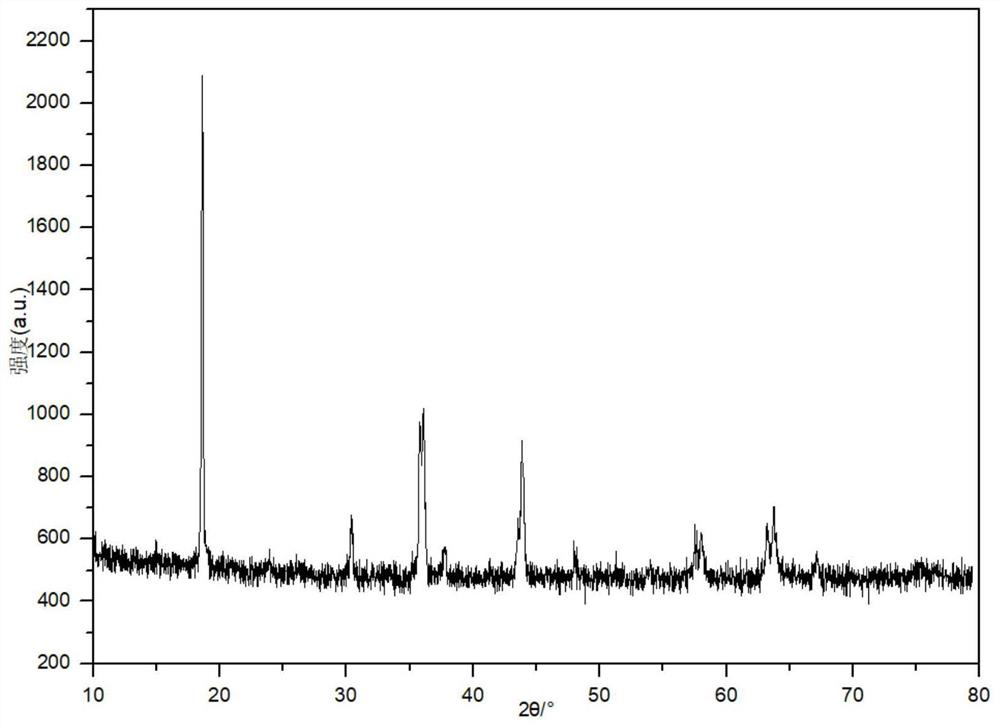

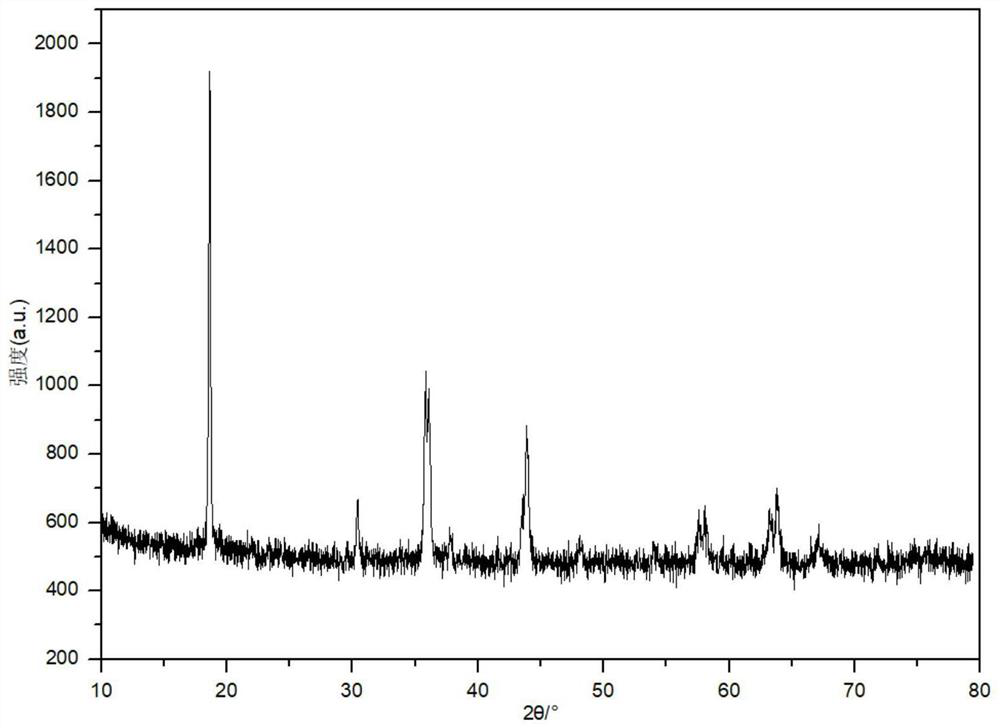

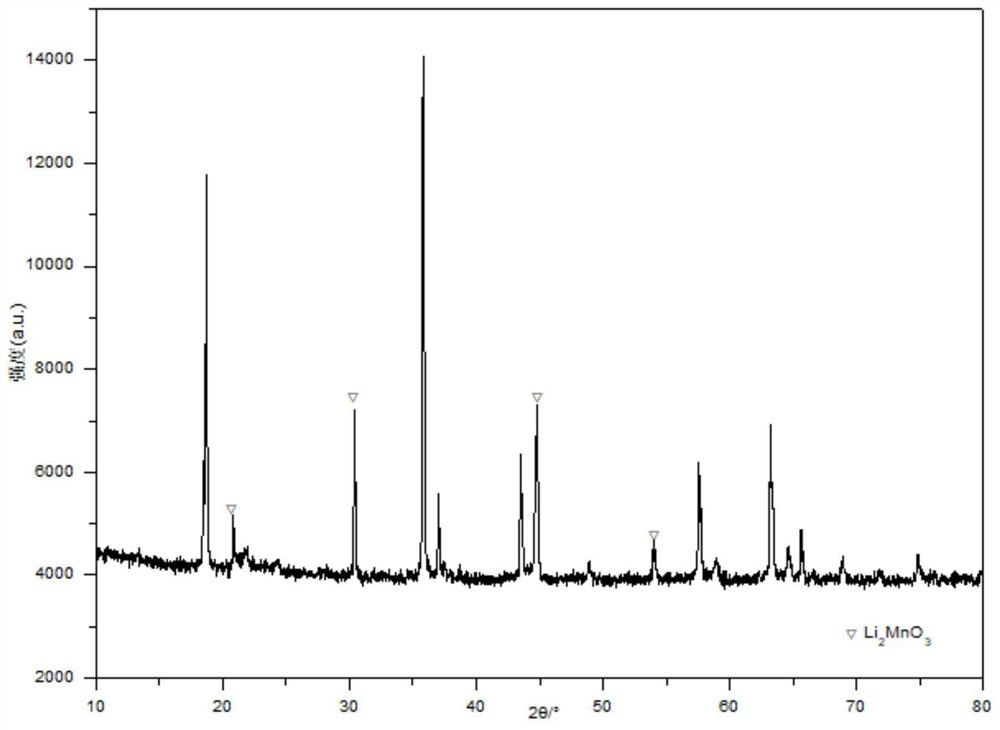

[0036] This application uses less lithium inorganic compounds and Fe x mn y (OH) 2 The precursor is oxidized and sintered, so that the finally prepared iron-manganese-based positive electrode material forms a lithium-poor structure. The lithium-poor structure not only ensures that the lithium content in the material is low, but also controls the valence state and crystal form of manganese well. On the one hand, part of the manganese in the material is positive tetravalent manganese. In the XRD spectrum of the iron-manga...

Embodiment 1

[0046] 1) Mix 500g ferrous chloride, 500g manganese acetate and 2000mL water in the reactor, add 300g ammonia complexing agent to the reactor, feed nitrogen into the reactor at a speed of 3L / min, heat the reactor When the dispersion liquid reaches 45°C, add sodium hydroxide solution to the reaction kettle to adjust the pH of the dispersion liquid to 12, and stir the dispersion liquid at 300rpm to carry out coprecipitation reaction. washed, and dried in an oven at 100 °C to obtain Fe 0.5 mn 0.5 (OH) 2 Precursor.

[0047] 2) In a dry environment, 100gFe 0.5 mn 0.5 (OH) 2 Precursor and 18.8g lithium hydroxide (n Li :( Fe +n Mn )=0.4) ball milled until uniform.

[0048] 3) Place the uniformly mixed material in a Nabertherm box furnace, and feed air into the box furnace at a flow rate of 4L / min, and raise the temperature to 700°C at a heating rate of 2°C / min, and keep it warm for 9 hours. Cool down to 100°C at a cooling rate of 3°C / min to obtain Li 0.4 Fe 0.5 mn 0.5 o ...

Embodiment 2

[0050] 1) Mix 500g ferrous chloride, 500g manganese acetate and 2000mL water in the reactor, add 300g ammonia complexing agent to the reactor, feed nitrogen into the reactor at a speed of 3L / min, heat the reactor When the dispersion liquid reaches 45°C, add sodium hydroxide solution to the reaction kettle to adjust the pH of the dispersion liquid to 12, and stir the dispersion liquid at 300rpm to carry out coprecipitation reaction. washed, and dried in an oven at 100 °C to obtain Fe 0.5 mn 0.5 (OH) 2 Precursor.

[0051] 2) In a dry environment, 100gFe 0.5 mn 0.5 (OH) 2 Precursor and 18.8g lithium hydroxide (n Li :( Fe +n Mn )=0.4) ball milled until uniform.

[0052] 3) Place the uniformly mixed material in a Nabertherm box furnace, and feed air into the box furnace at a flow rate of 4L / min, and raise the temperature to 700°C at a heating rate of 2°C / min, and keep it warm for 9 hours. An intermediate product is obtained.

[0053] 4) Under the above-mentioned air vent...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap